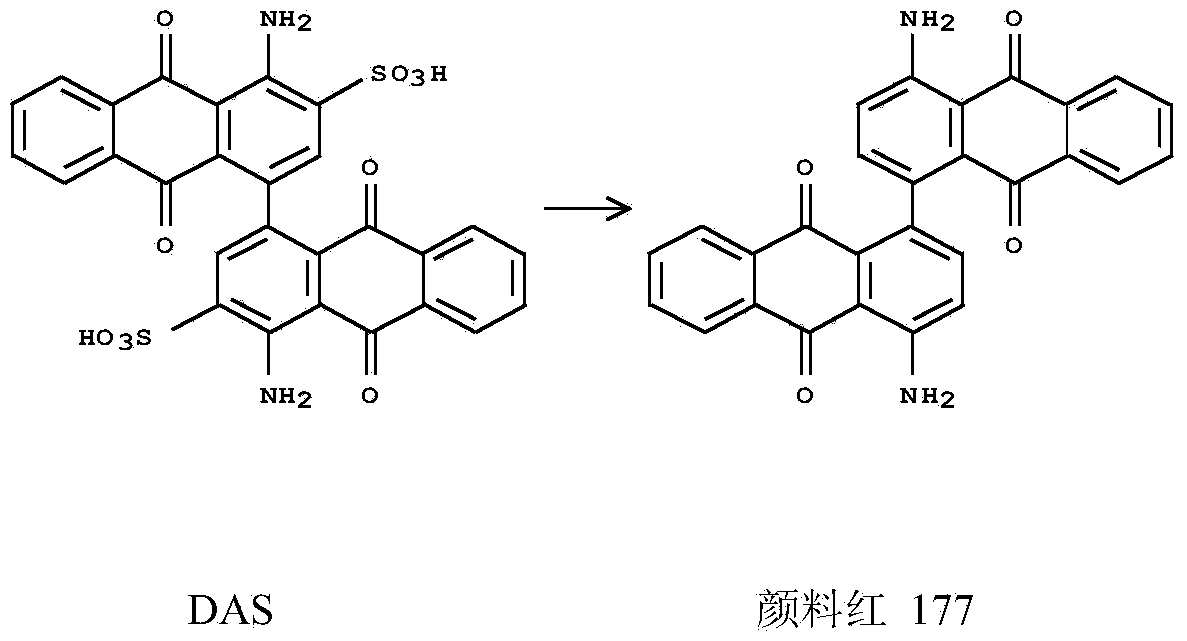

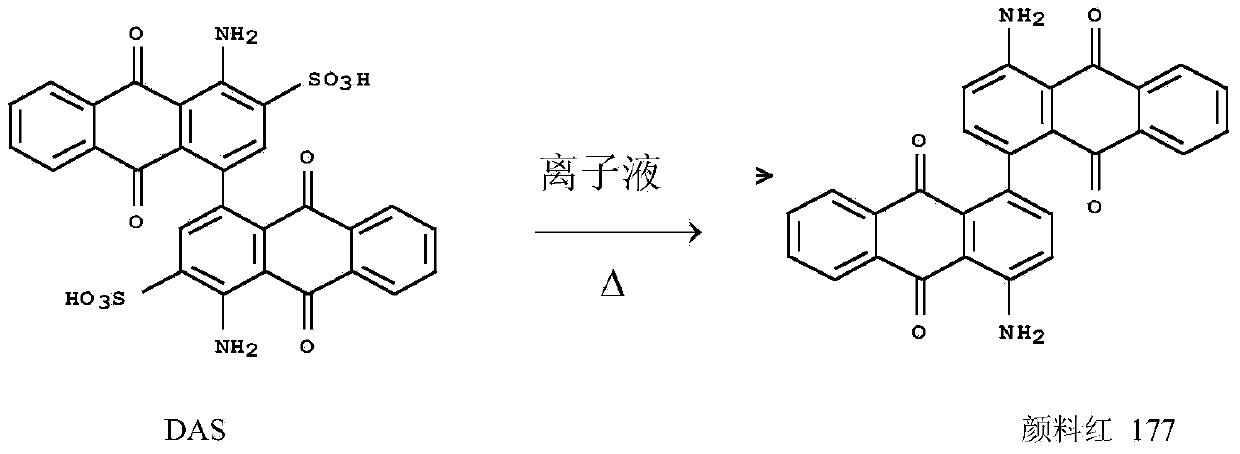

Method for preparing pigment red 177 in ionic liquid

An ionic liquid, pigment red technology, applied in chemical instruments and methods, anthracene dyes, organic dyes, etc., can solve problems such as intractability and recycling, restricting the production of pigment red 177, environmental protection issues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The weight ratio of BSMTF to DAS is 6:1;

[0017] The weight ratio of methanol solvent to DAS is 40:1;

[0018] Weigh 5 g of DAS and 30 g of BSMTF ionic liquid, and add them into a 300 mL four-neck flask. The flask was placed in an oil bath, stirred and heated to 140°C, and kept for reaction for 11 hours. Then the reaction mixture was cooled to below 50°C (methanol does not boil), and 200g of methanol solvent was added, stirred, and Pigment Red 177 was precipitated. The diluted mixture was filtered with suction, and the filter cake was dried at 80°C for 12 hours to obtain Pigment Red 177 in a yield of 97.9%. The methanol in the filtrate is recovered by distillation, and the ionic liquid obtained after the methanol is distilled is also recovered.

Embodiment 2

[0020] The weight ratio of BSMTF to DAS is 4:1;

[0021] The weight ratio of methanol solvent to DAS is 35:1;

[0022] Weigh 5 g of DAS and 20 g of BSMTF ionic liquid, and add them into a 300 mL four-neck flask. The flask was placed in an oil bath, stirred and heated to 150° C., and kept for 9 hours for reaction. Then the reaction mixture was cooled to below 50° C., diluted with 175 g of methanol solvent, stirred, and Pigment Red 177 was precipitated. After suction filtration, the filter cake was dried at 80°C for 12 hours to obtain Pigment Red 177 in a yield of 96.8%. The methanol in the filtrate is recovered by distillation, and the ionic liquid obtained after the methanol is distilled off is recovered.

Embodiment 3

[0024] The weight ratio of BSMTF to DAS is 8:1;

[0025] The weight ratio of methanol solvent to DAS is 45:1;

[0026] Weigh 5 g of DAS and 40 g of BSMTF ionic liquid, and add them into a 300 mL four-neck flask. The flask was placed in an oil bath, stirred and heated to 135° C., and kept for 6 hours for reaction. Then the reaction mixture was cooled to below 50° C., 225 g of methanol solvent was added to dilute the reaction mixture, stirred, and Pigment Red 177 was precipitated. After suction filtration, the filter cake was dried at 80°C for 12 hours to obtain Pigment Red 177 in a yield of 96.2%. The methanol in the filtrate is recovered by distillation, and the ionic liquid obtained after the methanol is distilled off is recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com