A two-pass radiation section furnace tube for ethylene cracking furnace

An ethylene cracking furnace and process radiation technology, which is applied in cracking, non-catalytic thermal cracking, petroleum industry and other directions, can solve the problems of shortened operation period of cracking furnace, shortened service life of furnace tubes, uneven heating of furnace tubes, etc., and achieves remarkable heating effect. , Improve production capacity, the effect of small furnace tube spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

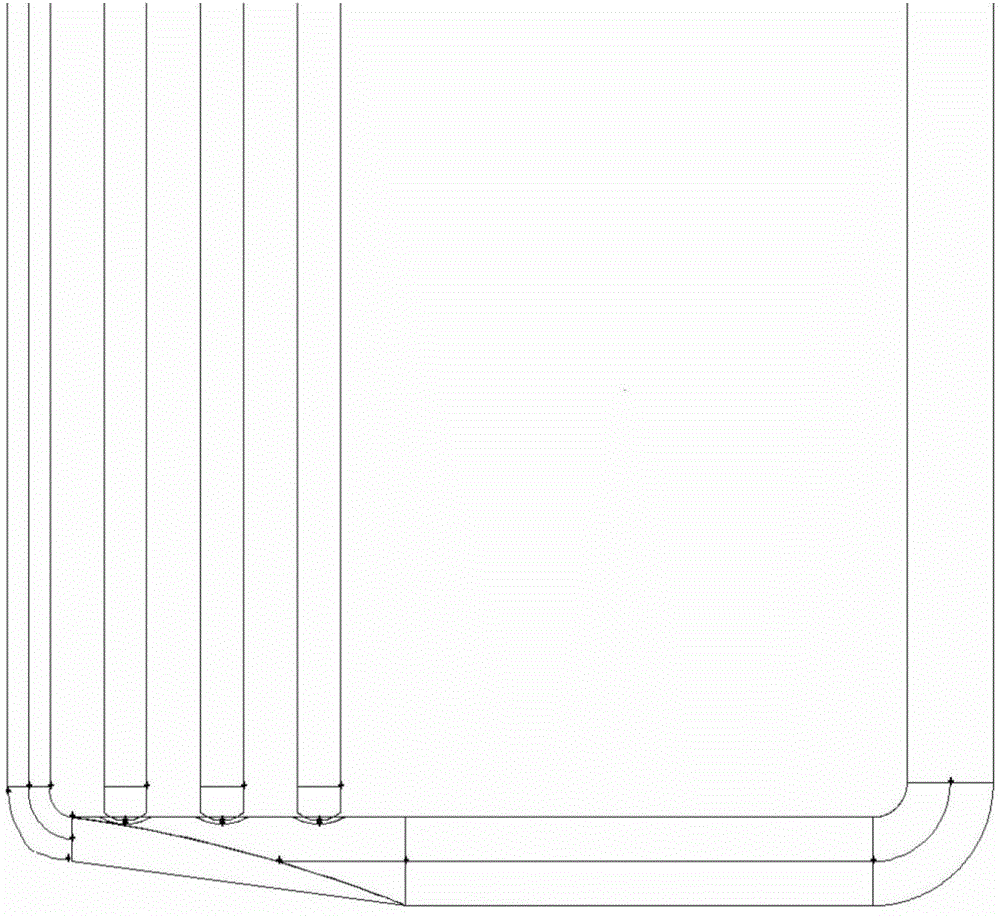

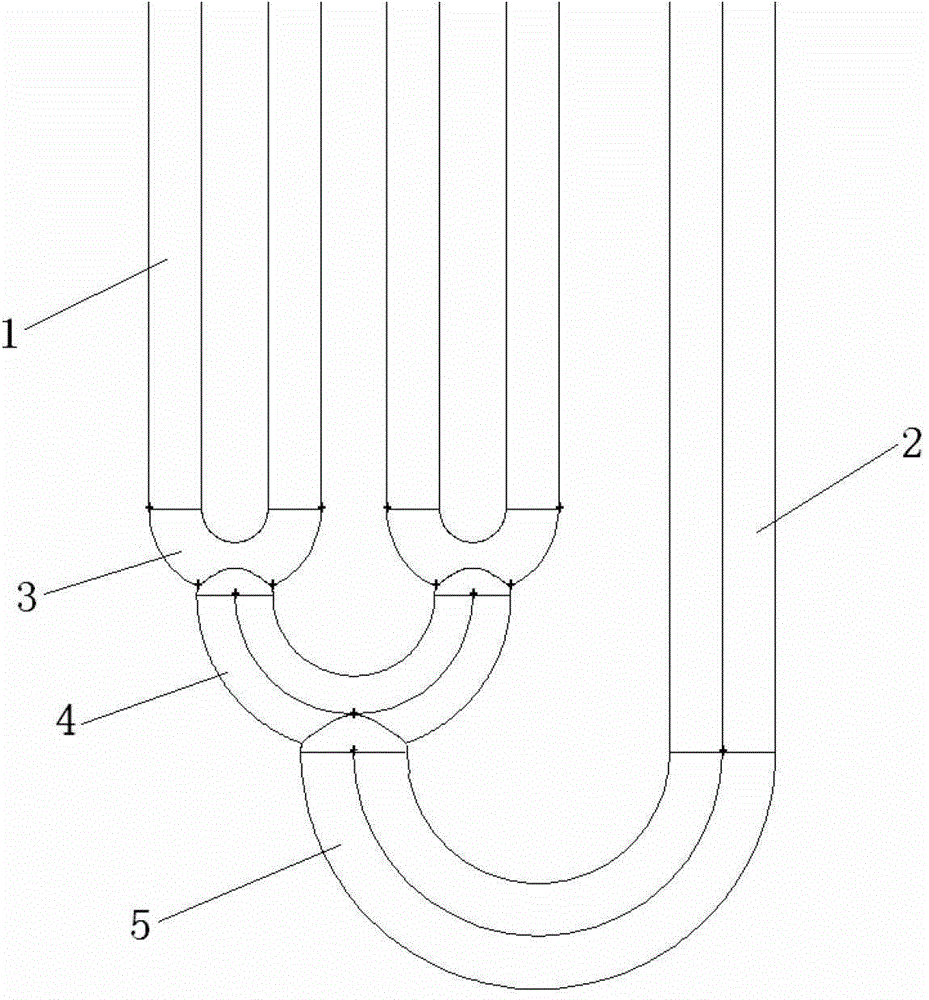

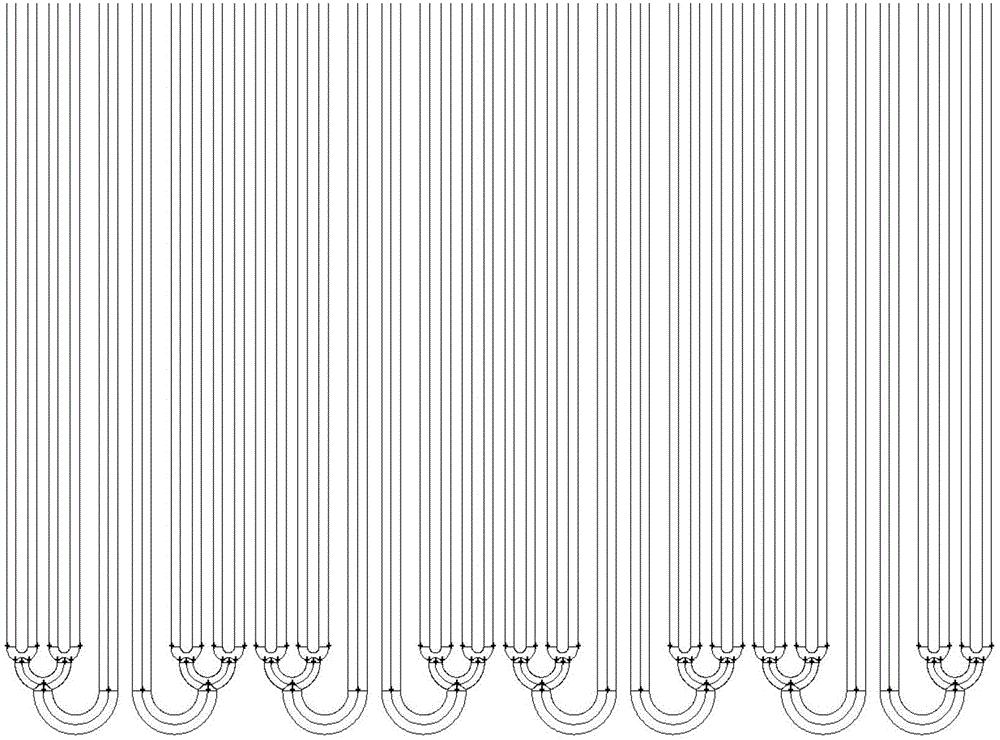

[0034] Such as figure 2 Shown, a two-pass radiant section furnace tube for ethylene cracking furnace.

[0035] The furnace tube is a two-pass vertical furnace tube. The number of the first-pass furnace tube is 4, and the second-pass furnace tube is 1 furnace tube. Every two first-pass furnace tubes 1 pass through an arc-shaped first-stage The collection pipe 3 is connected, and the two nozzles at the upper end of the first-stage collection pipe 3 are respectively connected to two first-stage furnace tubes 1, and the two first-stage collection pipes 3 are connected to an arc-shaped second-stage collection pipe 4, and the second The two nozzles at the upper end of the first stage collecting pipe 4 are respectively connected to the lower end nozzle of the first stage collecting pipe 3, the nozzle at the lower end of the second stage collecting pipe 4 is connected to the elbow 5, and the other end of the elbow 5 is connected to the second furnace pipe 2 .

[0036] The radian of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com