Method for producing high-viscosity-index lubricant base oil by hydrocracking-isodewaxing combination

A technology for hydroisomerization dewaxing and lubricating base oil, which is applied in the field of heavy lubricating base oil and light production, can solve the problems of increasing energy consumption and operating cost, reducing reaction efficiency, increasing equipment investment, etc., and reducing construction costs. Investment and operation difficulty of the device, simple process flow, low operating cost and low investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

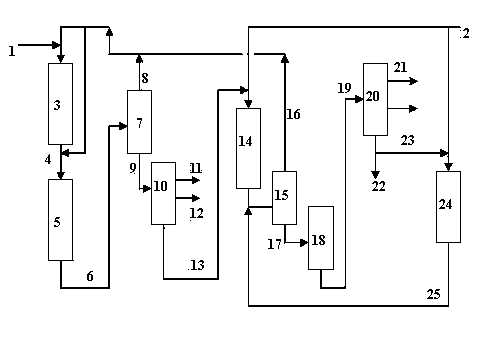

Image

Examples

Embodiment 1

[0049] This example introduces that the hydrocracking unit and the hydroisomerization dewaxing unit respectively use the catalysts in Table 2 to process the raw materials listed in Table 1. The hydrogen in the hydroisomerization dewaxing unit passes through once, and the tail hydrogen is used as supplementary hydrogen for hydrocracking. The reaction conditions and reaction results of the hydrocracking reaction zone and the hydroisomerization dewaxing unit are shown in Table 3. The vacuum fractionation column after the first hydroisomerization dewaxing reaction zone is provided with two side lines, which produce No. 4 base oil and No. 6 base oil respectively, and the bottom product of the tower produces No. 10 base oil. The split point of light lubricating oil base oil and heavy lubricating oil base oil is controlled at 480°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com