Multifunctional protective material for space environment of space station and preparation method thereof

A space environment and protective material technology, applied in the field of multifunctional protective materials, can solve the problem of increasing the weight quota of space environment protective materials in space stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of Multifunctional Protective Material Based on Aluminum and Carbon Nanotube Arrays

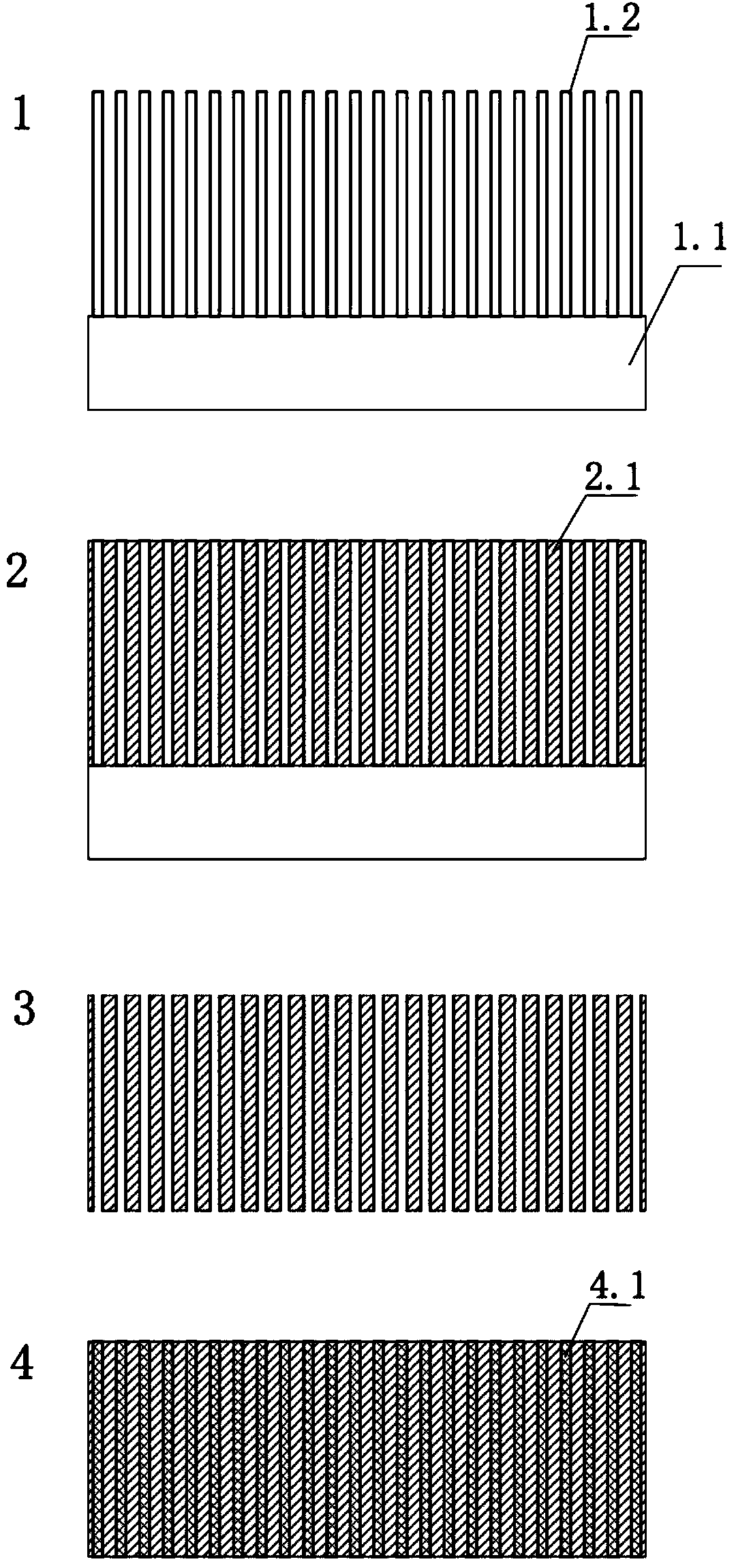

[0026] First, a carbon nanotube array sample (1) is prepared using known prior art (existing steps), carbon nanotubes are grown on a substrate (1.1), and each of the vertically aligned carbon nanotube arrays (1.2) The growth direction of carbon nanotubes is basically perpendicular to the substrate.

[0027] Secondly, the carbon nanotube array is heated to a high temperature of 650-700°C under Ar gas or vacuum conditions, and aluminum chips are placed on the surface of the carbon nanotubes in advance. The weight of the aluminum chips is based on the volume of the carbon nanotube array × (80%-90%) × Calculated from the density of aluminum. Keep the high temperature at 650-700° C. for 20 minutes, then cool down to room temperature, take out the sample, and obtain the carbon nanotube metal composite material.

Embodiment 2

[0030] Example 2 Preparation of multifunctional protective material of copper base and carbon nanotube array

[0031] First, a carbon nanotube array sample (1) is prepared using known prior art (existing steps), carbon nanotubes are grown on a substrate (1.1), and each of the vertically aligned carbon nanotube arrays (1.2) The growth direction of carbon nanotubes is basically perpendicular to the substrate.

[0032] Secondly, the carbon nanotube array is heated to a high temperature of 1100°C under Ar gas or vacuum conditions, and copper scraps are placed on the surface of the carbon nanotubes in advance. The weight of the copper scraps is calculated according to the volume of the carbon nanotube array × (80%-90%) × copper The density is calculated. Keep at a high temperature of 1100° C. for 30 minutes, then cool down to room temperature, and take out a sample to obtain a carbon nanotube metal composite material.

[0033] Thirdly, using mechanical cutting, grinding or lase...

Embodiment 3

[0035] Example 3 Preparation of multifunctional protective material of iron-based and carbon nanotube arrays

[0036]First, a carbon nanotube array sample (1) is prepared using known prior art (existing steps), carbon nanotubes are grown on a substrate (1.1), and each of the vertically aligned carbon nanotube arrays (1.2) The growth direction of carbon nanotubes is basically perpendicular to the substrate.

[0037] Secondly, the carbon nanotube array is heated to a high temperature of 1550°C under Ar gas or vacuum conditions, and iron filings are placed on the surface of the carbon nanotubes in advance, and the weight of the iron filings is calculated according to the volume of the carbon nanotube array × (80%-90%) × iron The density is calculated. Keep at a high temperature of 1550° C. for 30 minutes, then cool down to room temperature, and take out a sample to obtain a carbon nanotube metal composite material.

[0038] Thirdly, using mechanical cutting, grinding or laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com