Automatic variable diameter hole forming device installed on the drilling machine

A hole former, automatic technology, applied in drill bits, drilling equipment, earthwork drilling and other directions, can solve the problems of large friction resistance between the hole former and the soil, increased consumption of oil and other materials, and high equipment purchase costs, and achieves high The effect of labor productivity, consumption reduction, and purchase cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

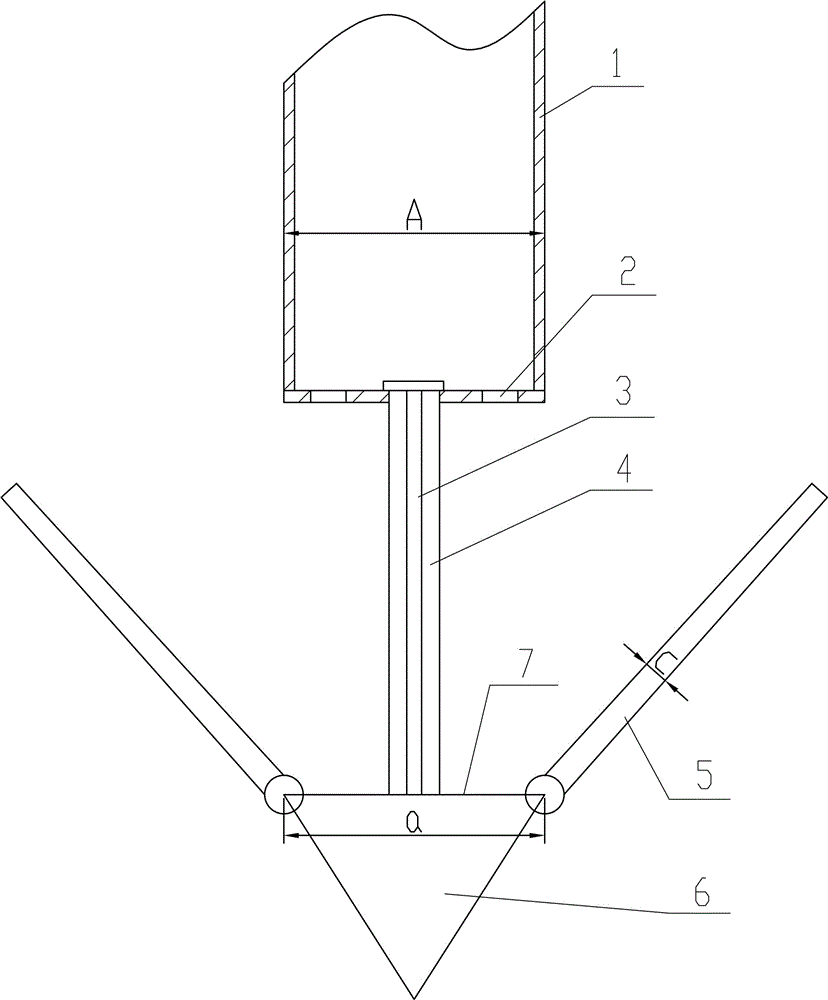

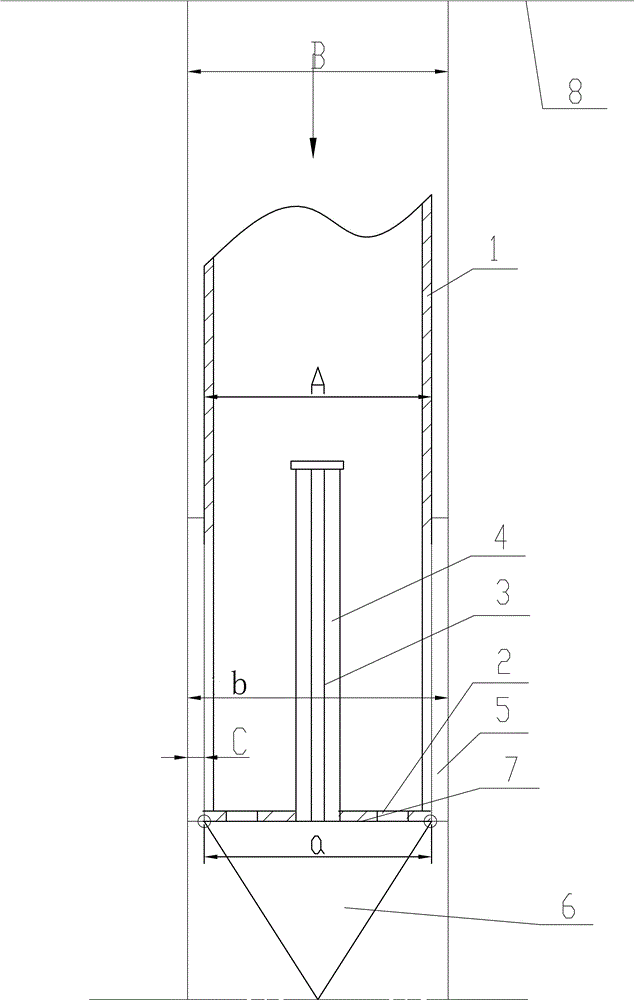

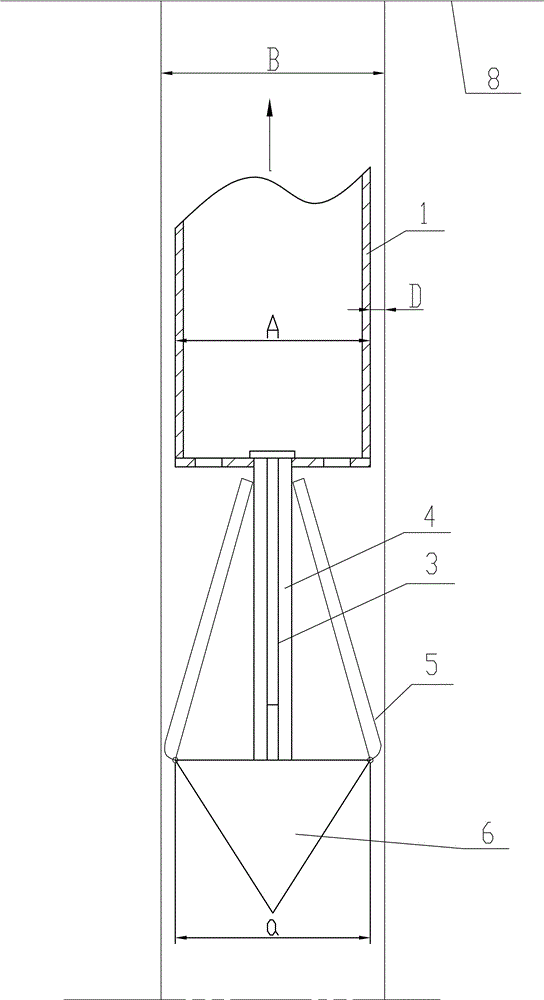

[0022] See attached figure 1 , the present invention comprises a pile pipe 1, a guide rod 4, a flap 5 and an inverted cone pile tip 6, the guide rod 4 is movably connected to the bottom of the pile pipe 1, and the lower end of the guide rod 4 is fixedly connected to the pile tip 6 3-6 flaps 5 are hinged on the edge of the upper end surface 7 of the pile point 6, and the flaps 5 are arranged side by side. When the hole is opened, the flaps 5 are closed and hold the pile pipe 1 tightly. After closing, there is a distance of 5-6 cm between two adjacent flaps 5, and a slender iron sheet or iron plate is welded on the pile pipe 1. (Its shape is also an arc matching the outer wall of the pile pipe 1). The iron sheet is located in the gap between the two flaps 5, and its length is basically the same as that of the flap 5; the diameter a of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com