Extensible swinging device for crushing, impacting and tunneling for underground coal mine

A telescopic swing, coal mine technology, used in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of small tunnel excavation section, non-mechanized operation, low safety factor, etc., to improve the level of single entry, improve the level of mechanization, safety Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

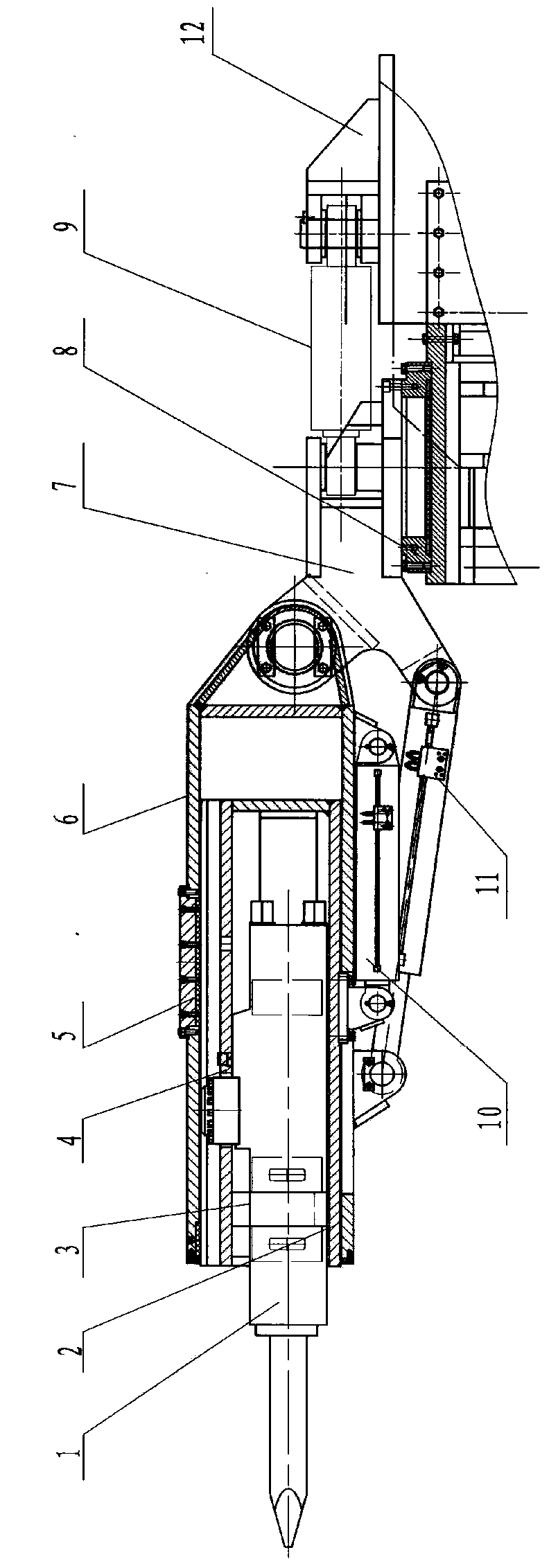

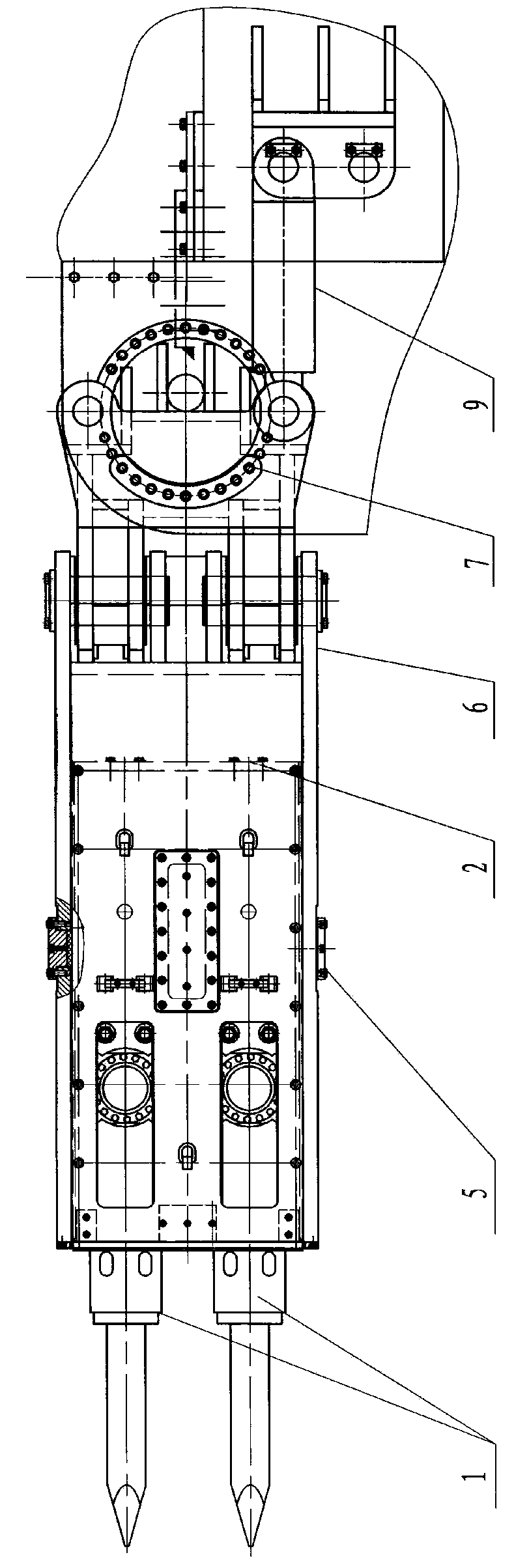

[0017] Such as figure 1 , figure 2 As shown, a telescoping and swinging device for crushing impact excavation in underground coal mines includes a fixed seat 12, wherein two sets of telescopic arms are installed on the fixed seat 12, and each set of telescopic arms is composed of two breaking hammers 1 and inner sleeves 2 , briquetting block 3, cover plate 4, adjusting pad 5, outer sleeve 6, slewing seat 7, slewing bearing 8, slewing cylinder 9, telescopic cylinder 10 and lifting cylinder 11, the two breaking hammers 1 are pressed The block 3 is loaded into the inner sleeve 2 and fixed with bolts through the cover plate 4. The inner sleeve 2 is installed in the outer sleeve 6 and the outer sleeve 6 and the outer sleeve 6 are adjusted through the adjustment block 5 provided on the outer sleeve 6. In the gap between the inner sleeves 2, one end of the telescopic cylinder 10 is connected to the outer sleeve 6, and the other end of the telescopic cylinder 10 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com