Infrared liquefied gas furnace and infrared gas furnace end

A gas stove, infrared technology, which is applied to household stoves/stoves, gas fuel burners, burners, etc., can solve the problems of nitrogen monoxide gas overflow, low thermal efficiency, poor wind resistance, etc., and achieves obvious effects, compact and reasonable structure. , the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A liquefied gas infrared gas stove, comprising an infrared gas burner 2, a support 1 and a gas delivery pipe 3, the infrared gas burner 2 is embedded in the middle and upper part of the support 1, the gas delivery pipe 3 is connected with the infrared gas The center of the bottom of the burner 2 is connected.

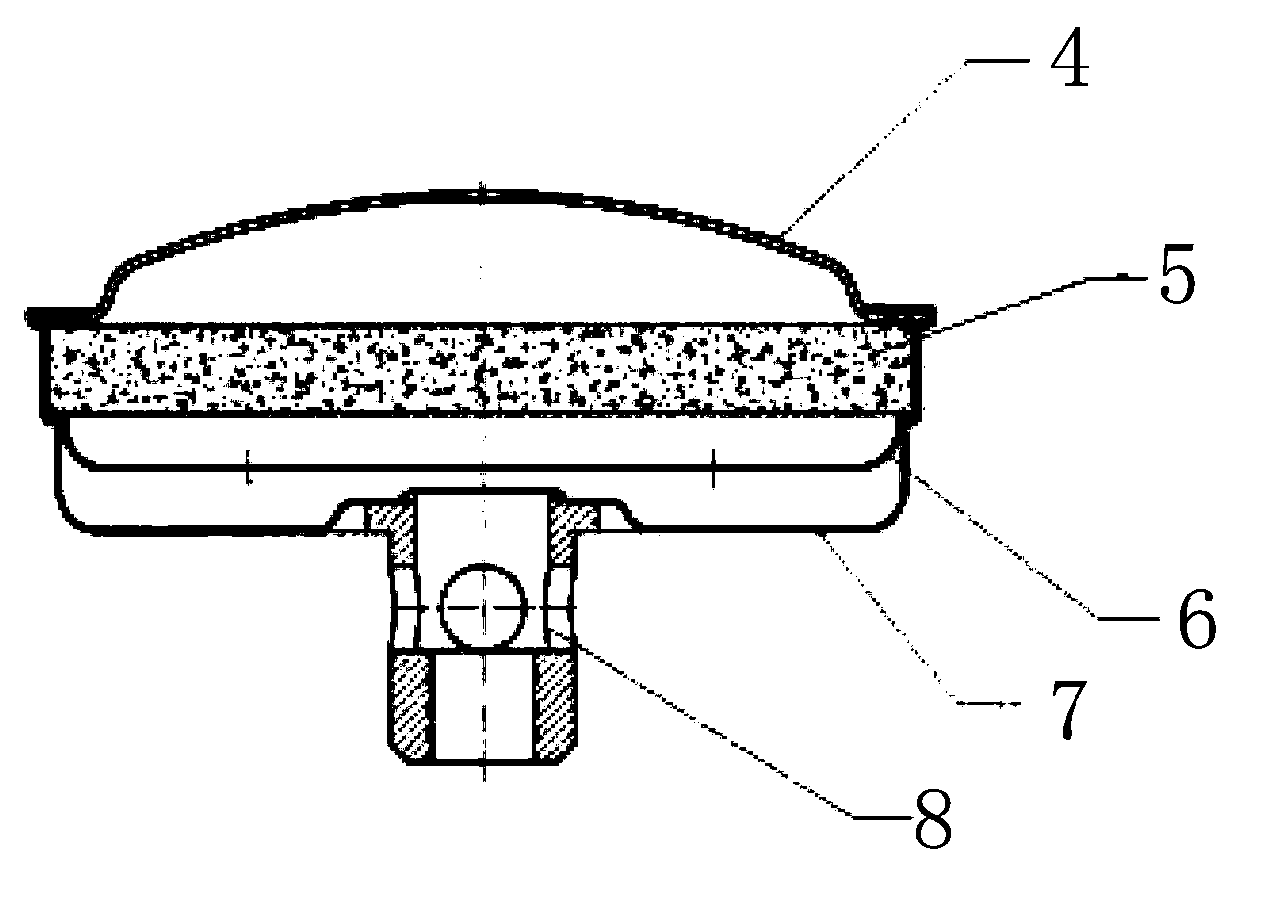

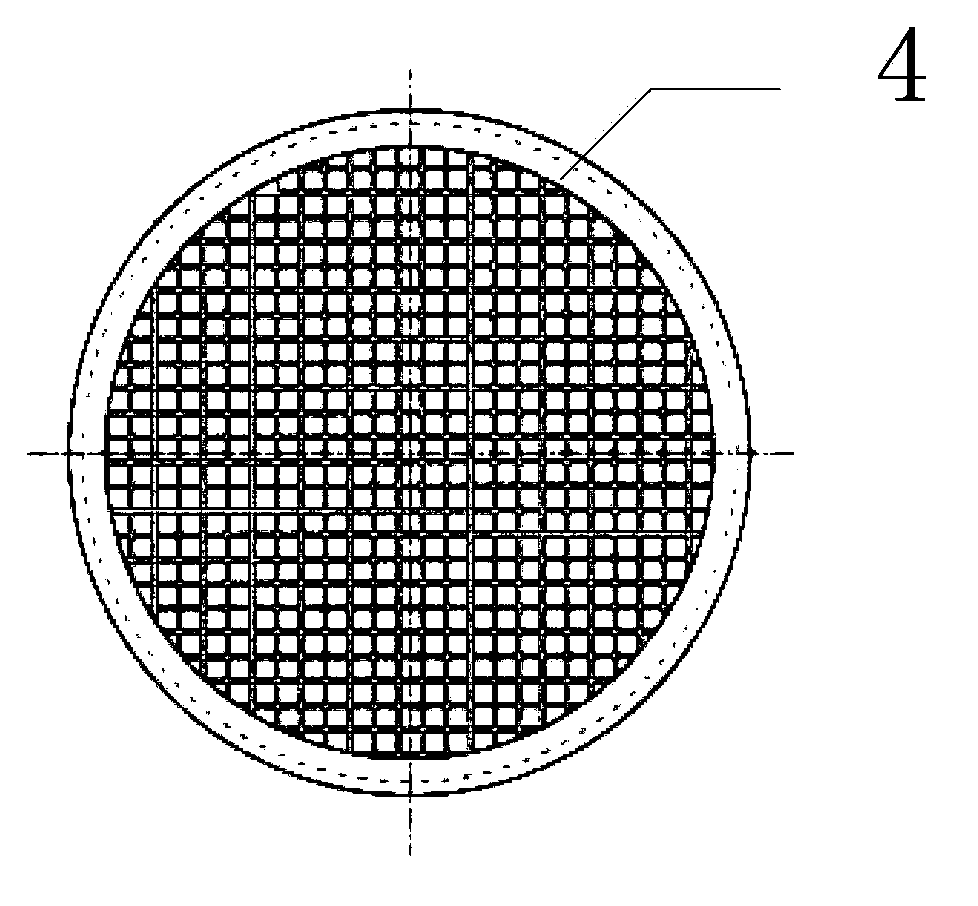

[0037] The infrared gas burner head 1 includes a bowl-shaped metal mesh cover 4, a metal gas block 5, a gas rectifying bowl 6, a casing 7 and an air intake pipe 8;

[0038] The metal mesh cover 4 is covered on the upper surface of the metal gas block 5, the gas rectifying bowl 6 is covered on the lower surface of the metal gas block 5, and the outer shell 7 is covered on the outside of the gas rectifying bowl 6, so One end of the intake pipe 8 is fixed to the middle part of the casing 7 and communicates with the cavity between the metal gas block 5 and the casing 7 , and the other end communicates with the gas delivery pipe 3 .

[0039] The material of the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com