Water recovery system for cooling equipment

A technology for cooling equipment and water recovery, applied in the direction of water shower coolers, lighting and heating equipment, direct contact heat exchangers, etc., can solve the problems of high power consumption in four seasons, increased coal consumption, and evaporation loss. Recycling power and other issues to achieve the effect of reducing costs and reducing water damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

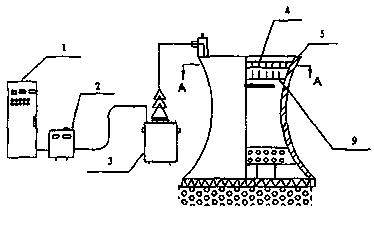

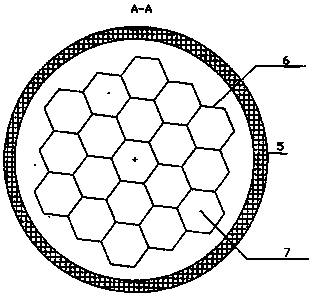

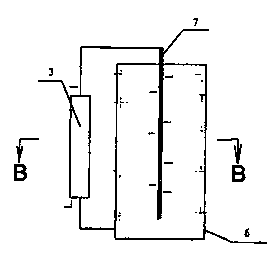

[0020] Such as figure 1 , shown in 2, 3, and 4, the input voltage of the control cabinet 1 of the power input is 220-380V alternating current, and the power supply is electrically connected with the high voltage generator 3 through the safety control cabinet 2, because the working voltage of the present invention is 1-120KV High-voltage direct current, the safety control cabinet 2 monitors the safety of the working environment. When a fault occurs, the safety control cabinet 2 can immediately cut off the power to ensure the safety of equipment and personnel. The high-voltage generator 3 outputs high-voltage direct current and is connected to the water recovery device 4 The water recovery device 4 is composed of a water collecting electrode 6 and a corona electrode 7. The positive pole of the high-voltage direct current is connected to the water collecting electrode 6, and the negative pole is connected to the corona electrode 7. The water recovery device 4 is fixed on the top...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap