Dynamic liquid level height measuring device and dynamic liquid level height measuring method as well as closed-loop control system and closed-loop control method

A technology of liquid level height and measuring device, which is applied in liquid level control, non-electric variable control, control/adjustment system, etc., can solve the problems of measurement accuracy, increase device loss, easy damage, etc., and achieve simple and accurate calculation methods. , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

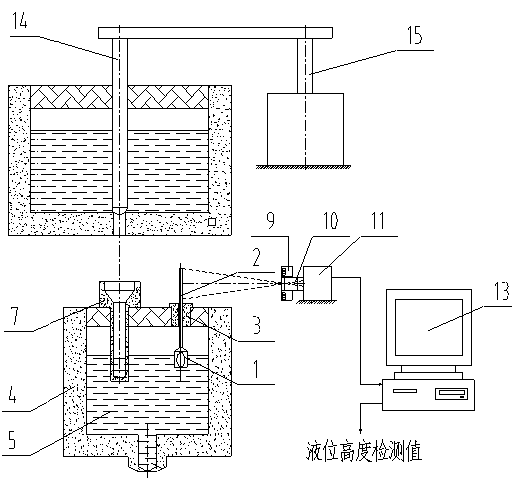

[0041] This embodiment provides a dynamic liquid level height measuring device, which includes a container to be measured 4, which is a device for measuring the height of molten steel in this embodiment. Therefore, the container to be measured 4 is a ladle, and the liquid to be measured 5 is molten steel . A float 1 is provided on the molten steel in the container 4 to be tested. One end of the float 1 is set in the molten steel, floats on the molten steel, and floats up and down as the liquid height changes. The other end is connected to a float rod 2. The float rod 2 extends outward through the guide mechanism 3 . The guide mechanism 3 here is made of high-temperature-resistant metal, which passes through the wall of the container to be tested 4 and has a through hole in the middle, and the inner wall of the through hole is smooth. The guiding mechanism 3 moves with the movement of the float 1. The float 1 adopts a refractory material with a density lower than that of the l...

Embodiment 2

[0046] The measurement and calculation method using the dynamic liquid level height measurement device described in Embodiment 1 of the present invention includes the following steps:

[0047] The float rod 2 and the float 1 float on the molten steel, the front end of which protrudes out of the guide mechanism 3 , the light source 9 illuminates the float rod 2 to make the float rod 2 clearer, and the lens 10 will be exposed on the upper part of the guide mechanism 3 The height of the float rod 2 is imaged on the photosensitive element CCD of the camera device 11 , and the camera device 11 transmits the real image formed by the float rod 2 on the photosensitive element CCD to the data processor 13 in real time.

[0048] After the device is installed, it is necessary to calculate the calibration coefficient C under the working conditions at this time, measure the length L0 of the extension section located outside the guide mechanism 3 at this time, and then the data processor 13 ...

Embodiment 3

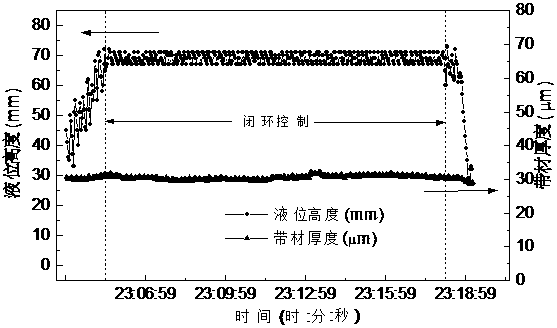

[0052] In this embodiment, a closed-loop control system is provided, including a container to be tested 4 and a liquid replenishment container. The container to be tested 4 is provided with a liquid to be tested 5 , and the liquid replenishment container is provided with a supplementary liquid. In this implementation, the In practical application of the container to be tested 4 and the liquid replenishment container, the preferred ones are the molten steel ladle to be tested and the liquid replenishment ladle, the liquid is preferably molten steel, the liquid replenishment container is arranged above the container to be tested 4, and the liquid replenishment port of the liquid replenishment container is The plug rod 14 is controlled by the plug rod actuator 15 to open or close, and the liquid replenishment port is aligned with the drainage port 7 in the container 4 to be tested. The drainage port 7 is preferably a funnel-shaped mechanism. The above-mentioned dynamic liquid leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com