Manufacturing method of reticle

A manufacturing method and reticle technology, which is applied to the photoplate-making process, optics, instruments, etc. of the patterned surface, can solve problems such as complex processes, and achieve the effects of simple process, improved production efficiency, and improved alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

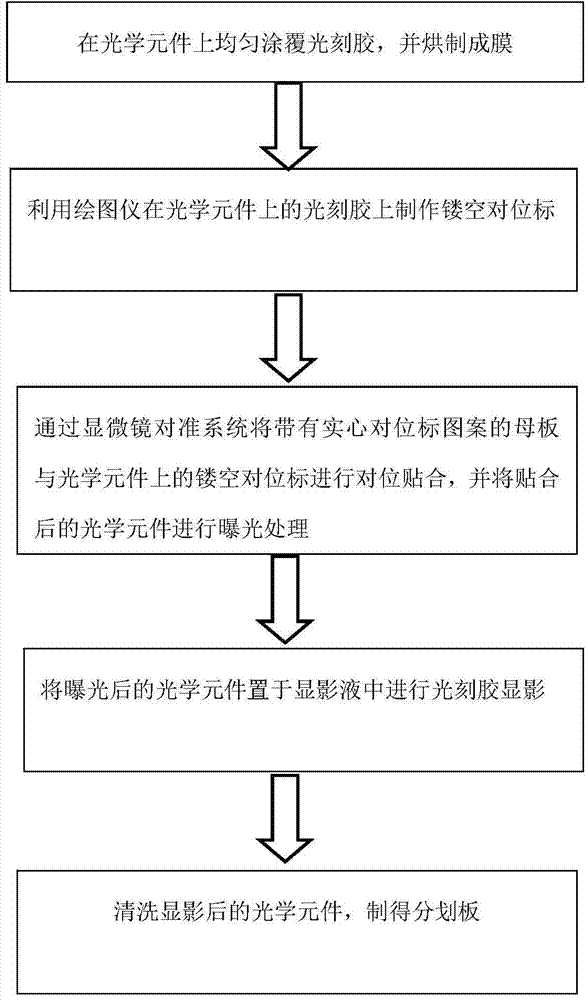

[0036] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

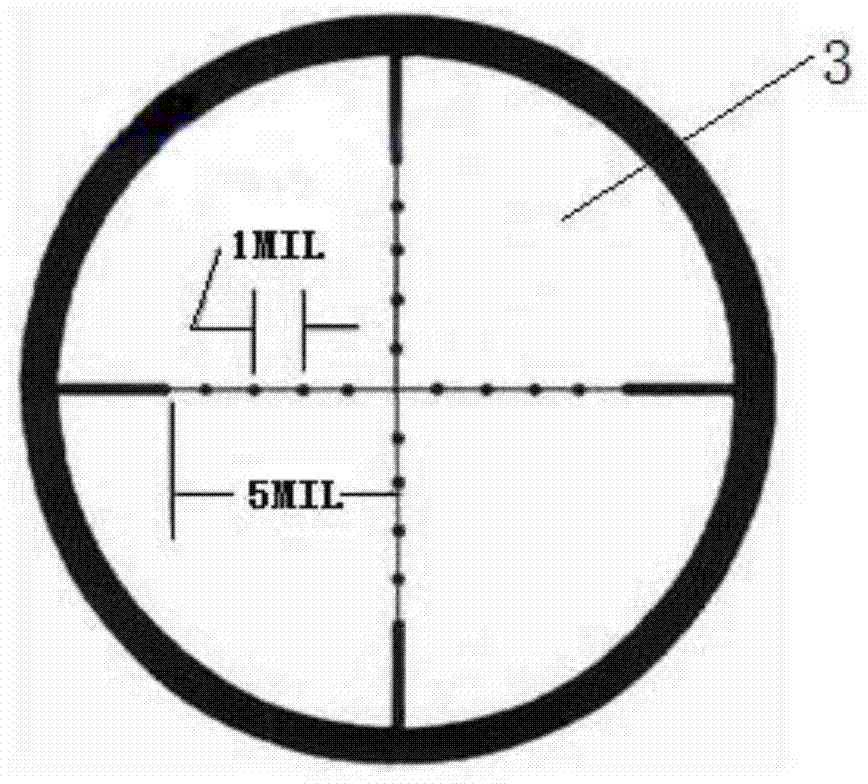

[0037] like figure 1 As shown, the present invention provides a manufacturing method of a reticle, wherein the manufacturing method comprises the following steps:

[0038] Step 1, uniformly coat the photoresist on the optical element, and bake it into a film; here, the thickness of the photoresist coating is 1 μm-10 μm, and the thickness of the photoresist film after baking is 1 μm~ 10 microns;

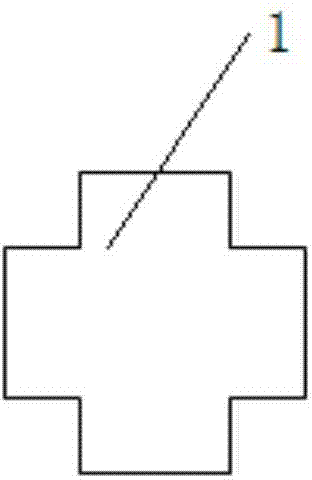

[0039] Step 2, using a laser plotter to make a hollow alignment mark on the photoresist on the optical element;

[0040] Step 3, aligning and bonding the motherboard with the solid alignment mark pattern and the hollow alignment mark on the optical element through the microscope alignment system, and exposing the bonded optical element;

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com