Biomembrane unit and membrane bioreactor

A biofilm and membrane cloth technology, applied in the field of new flat-type biofilm units, can solve the problem of low circulation efficiency of flat-plate membrane units, and achieve the effects of smooth water circulation and stable water output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

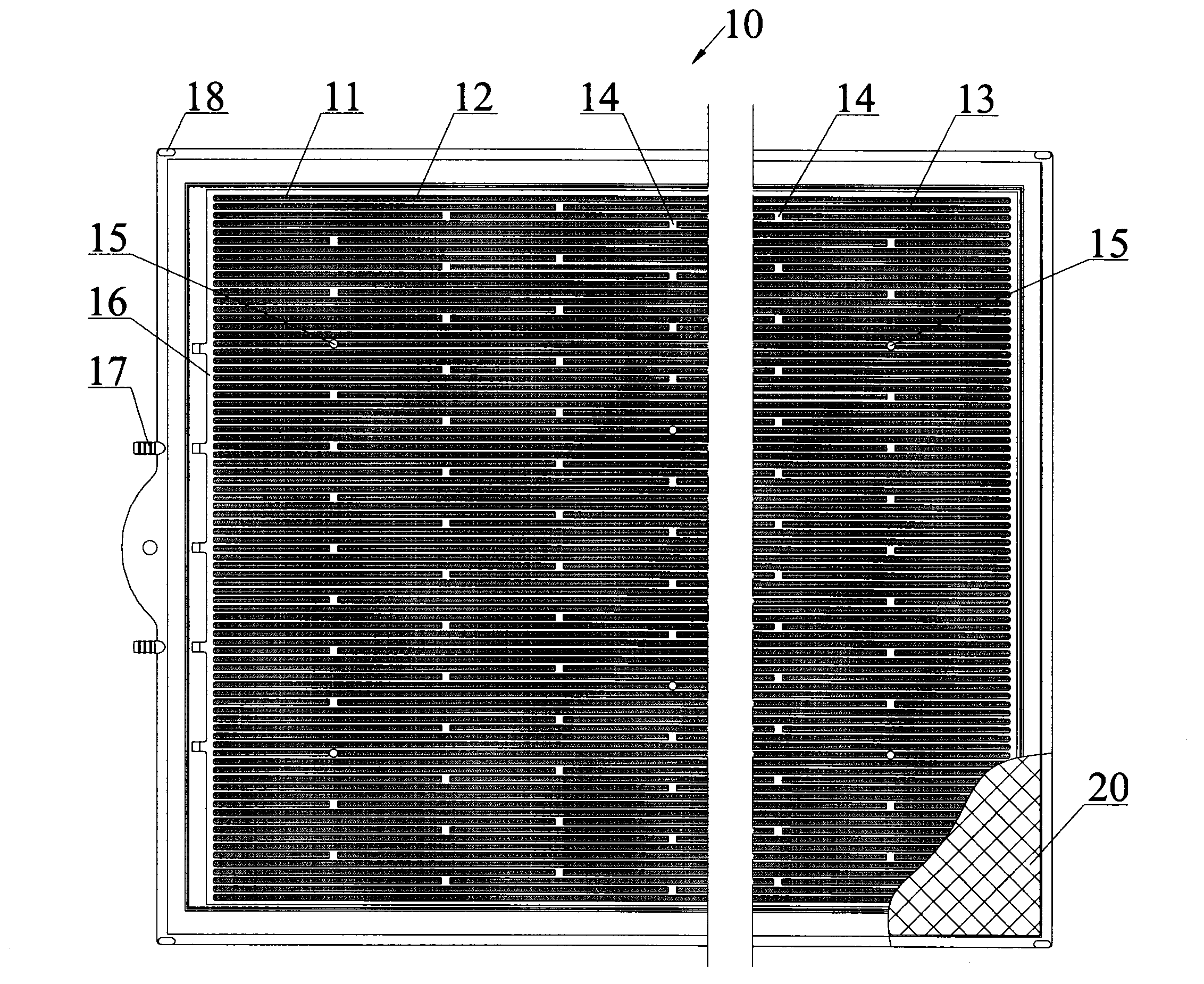

[0015] Such as figure 1 As shown, the present invention provides a kind of biofilm unit that can be put into the sewage pond to be treated. The biofilm unit includes a support plate 10, a film cloth 20 suitable for the size of the support plate 10, and fixes the two sides of the support plate 10 by hot-melt welding respectively. On the welding pattern, a film cloth 20 is fixed on the front side of the support plate 10 , and a film cloth 20 is fixed on the back side of the support plate 10 . The water outlet 17 of the support plate 10 is connected to the water pump to pump water. Under the action of the water pump, a negative pressure is formed inside the biofilm unit, and the sewage penetrates from the outside of the biofilm unit to the inside under the action of the negative pressure; under the separation of the membrane cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com