A kind of preparation method of fine spherical sm-fe-n series permanent magnetic powder

A technology of sm-fe-n, permanent magnet powder, applied in the field of preparation of fine spherical Sm-Fe-N permanent magnet powder, can solve the problems of low oxygen content, low raw material cost, long cycle, etc., and achieve controllable nitrogen content , the effect of low oxygen content and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

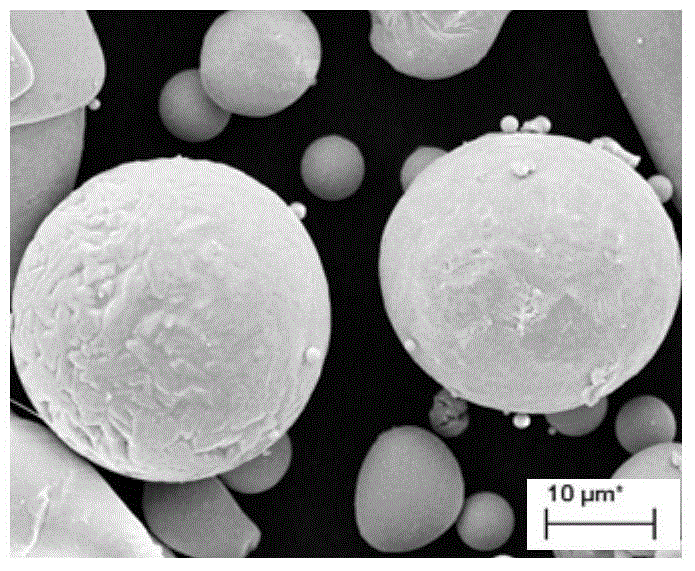

[0021] Embodiment 1: the preparation of Sm2Fe17N3 powder (prepared Sm2Fe17N3 powder SEM photo as figure 1 shown):

[0022] Design the Sm10.6Fe89.4 (wt%) alloy composition, considering the 15wt% loss of samarium element ingredients, put the prepared Sm and Fe raw materials into the melting crucible, after vacuuming, under the protection of high-purity argon, heat up to 1400 -1600℃, induction smelting samarium-iron alloy; pour the refined samarium-iron alloy liquid into the heat preservation crucible, and enter the guide tube and nozzle, the samarium-iron alloy liquid coming out of the guide tube nozzle is atomized and broken into a large number of small pieces by 5MPa argon gas During the rapid solidification of the droplets into spherical or sub-spherical particles, nitrogen gas of 0.4MPa is quickly applied to make it nitriding, so as to obtain Sm-Fe-N fine spherical powder, which is settled in the atomization tower. Fall into the powder collection tank, the powder particle ...

Embodiment 2

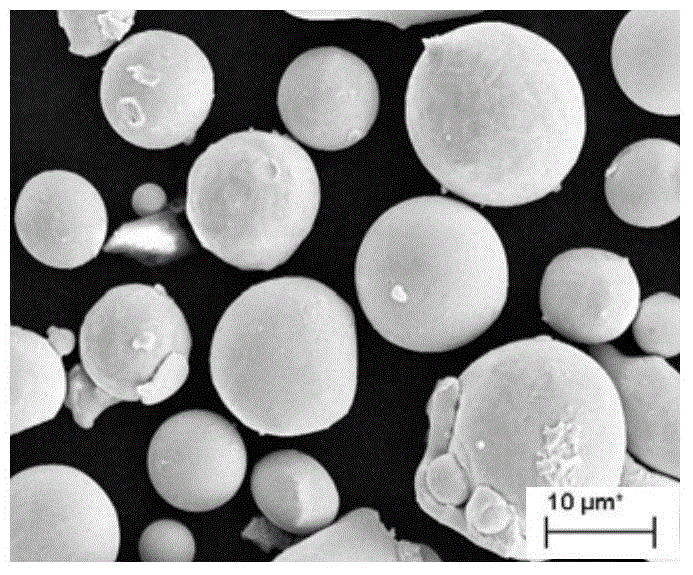

[0023] Example 2: Preparation of Sm1Fe9N2.8 powder (the SEM photo of the prepared Sm1Fe9N2.8 powder is as follows figure 2 shown):

[0024]Design the composition of Sm10.1Fe89.9 (wt%) alloy, considering the 15wt% loss of samarium element ingredients, put the prepared Sm and Fe raw materials into the melting crucible, after vacuuming, in a vacuum environment, heat up to 1400-1600°C , induction melting of samarium-iron alloy; pour the refined samarium-iron alloy liquid into the heat preservation crucible, and enter the guide tube and nozzle, and the samarium-iron alloy liquid coming out of the guide tube nozzle is atomized and broken into a large number of fine droplets by 8MPa argon gas , in the process of rapid solidification of droplets into spherical or sub-spherical particles, 0.4MPa nitrogen gas is quickly applied to make it nitriding, so as to obtain Sm-Fe-N fine spherical powder, which settles in the atomization tower and falls into the collection In the powder tank, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com