Hot-pressing printing method

A printing method and technology of printed matter, applied in the directions of printing, post-processing of printing, printing device, etc., can solve the problems of lower product quality, high production cost and high loss, achieve environmental protection, solve the problem of inaccurate positioning, and improve the performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

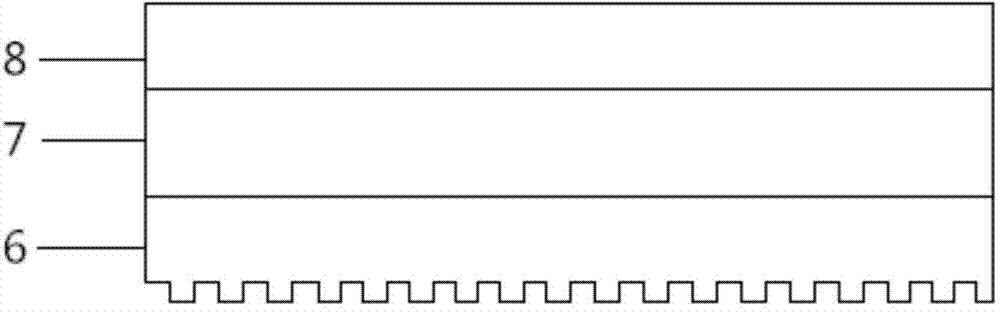

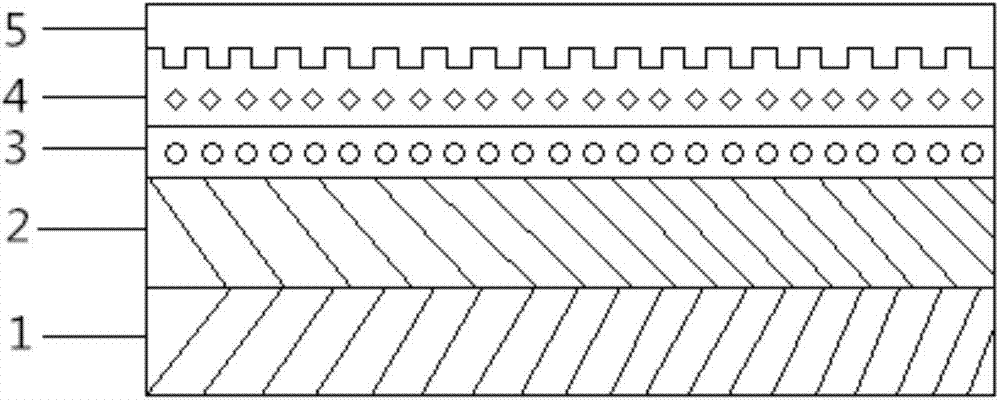

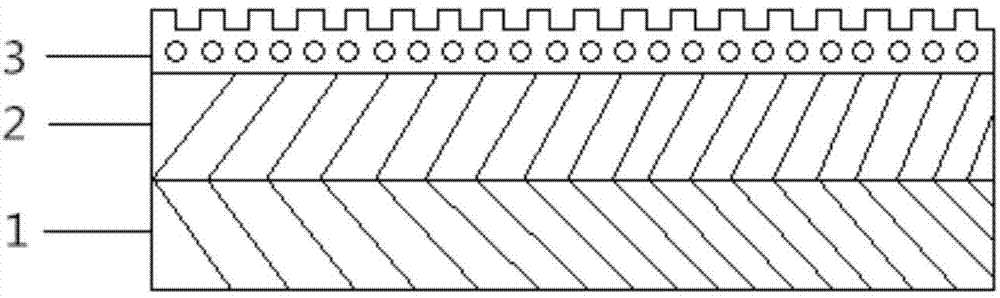

[0038] In the existing laser holographic process, the embossed holographic pattern on the nickel plate is transferred to the PET film by hot pressing, and the PET film with the laser holographic pattern is obtained. Its microstructure is as follows: figure 1 As shown, it consists of an aluminum coating layer 6, a release layer 7 and a PET film layer 8. There are two main types of laser holographic technology applied to printed matter: self-adhesive and transfer film. The self-adhesive process is to coat the laser holographic PET film with a layer of water-based glue and combine it with the release paper. After die-cutting, peel off the PET film and paste it on the printed matter. The transfer film process is to apply a layer of hot melt adhesive on the back of the laser holographic PET film, and use a hot stamping machine to heat and press the PET film to peel off and iron the printed matter. The microstructure of this printed matter is paper layer 1, ink layer 2, varnish lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com