Transfusion soft bag heat-seal strength on-line detecting device and transfusion soft bag production line

A technology for infusion soft bags and detection devices, which is applied in the field of on-line detection devices for heat sealing strength of infusion soft bags and infusion soft bag production lines. Labor intensity, simple and reliable detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

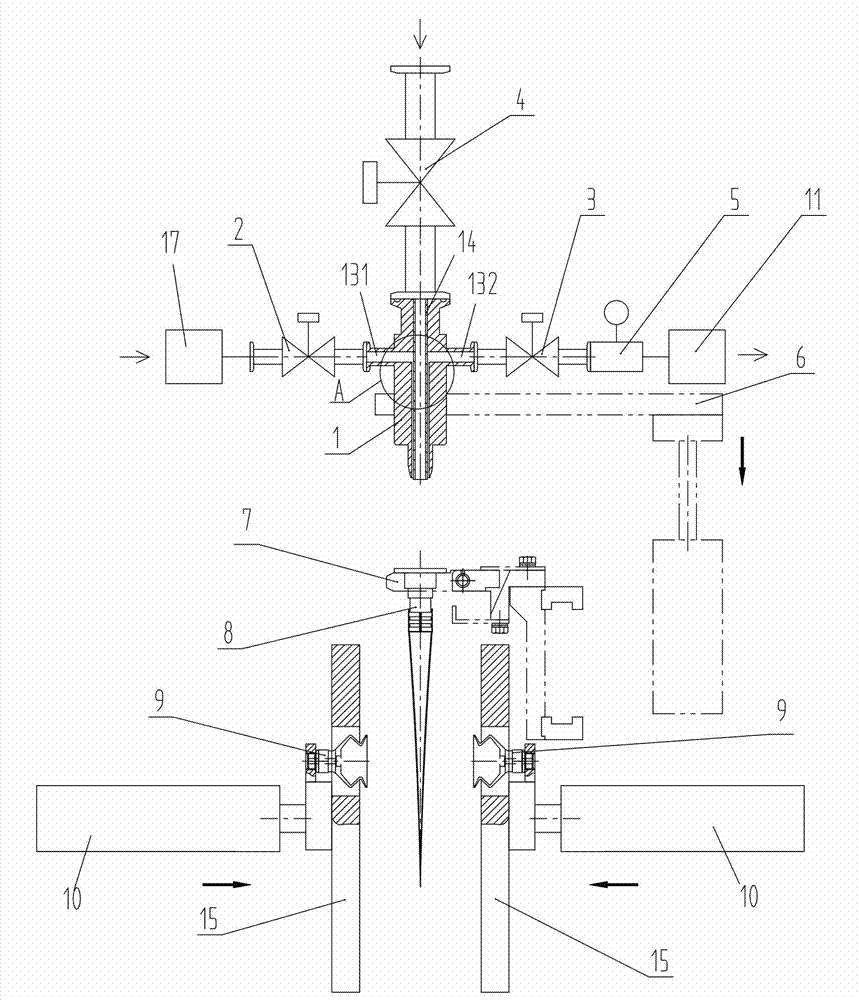

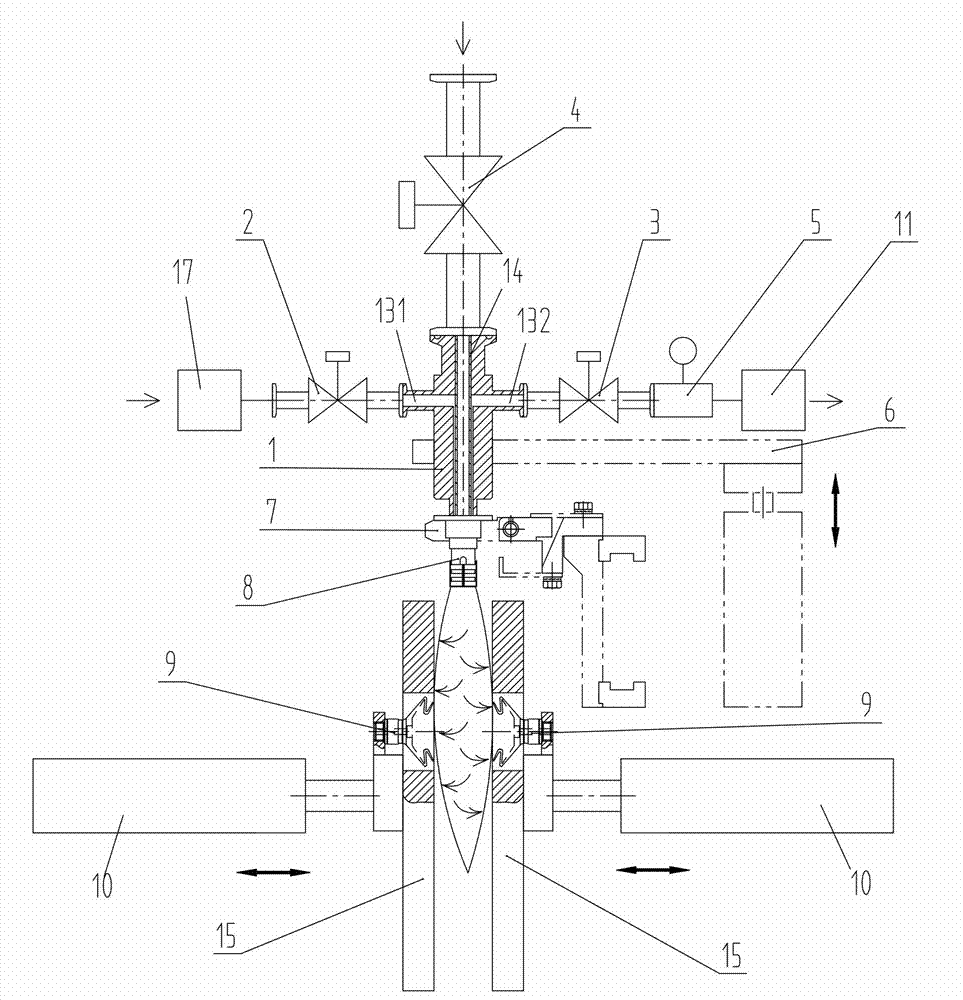

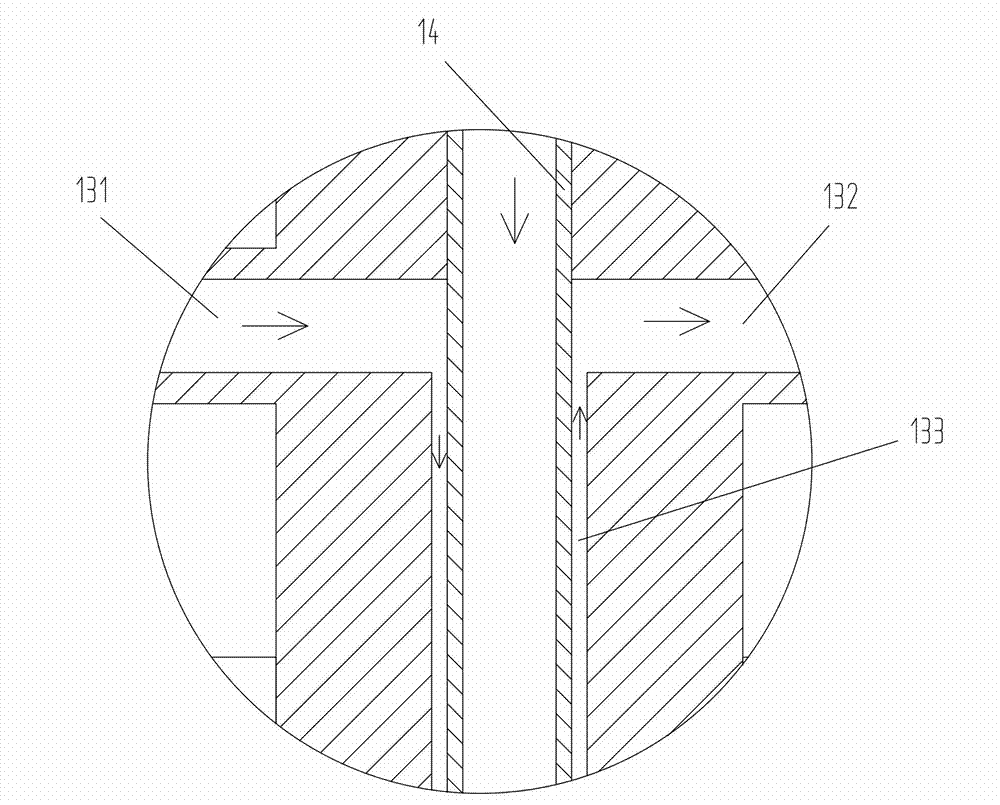

[0026] Such as figure 1 , figure 2 , image 3 As shown, the on-line detection device for the heat sealing strength of the infusion soft bag of the present invention is located at the filling station of the infusion soft bag production line. The filled filling needle 14 is provided with a liquid filling on-off valve 4 on the liquid path connected to the filling needle 14 . The needle filling part 1 can move up and down under the drive of the filling lifting part 6. When the needle filling part 1 descends and presses and seals with the interface of the infusion soft bag 8, the filling needle 14 is just communicated with the infusion soft bag 8. The on-line detection device for heat seal strength of soft infusion bags of the present invention includes an inflatable passage 131 provided on the filling needle part 1 for communicating with the soft infusion bag 8 to be tested, an inflatable part 17 connected to the inflatable passage 131, and a detection assembly. Like the filli...

Embodiment 2

[0033] Such as Figure 4 As shown, the structure of this embodiment is roughly the same as that of Embodiment 1, except that the vacuum degree detector 5 and the vacuum suction bag part 9 are removed, and the air path between the inflatable part 17 and the inflatable channel 131 and A flow meter 12 is arranged on the air path between the air extraction component 11 and the air extraction channel 132 .

[0034]The detection principle is as follows: first, the inflatable part 17 fills the infusion soft bag 8 with compressed gas of a set pressure and maintains the pressure for a certain period of time, monitors the intake flow through the flow meter 12, then closes the intake on-off valve 2, opens the The air outlet on-off valve 3, the air pumping part 11 starts to pump air, pump out the compressed gas in the infusion soft bag 8, and collect data through the flow meter 12, if the flow rate of the extracted gas matches the intake flow rate, it means that the gas in the infusion so...

Embodiment 3

[0036] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 2 is that the detection component includes a pressure sensor 18 arranged on the air path between the intake on-off valve 2 and the inflation channel 131 .

[0037] The detection principle is as follows: fill the infusion soft bag 8 with compressed gas of a set pressure and keep the pressure for a certain period of time, then close the air intake on-off valve 2, if the detection data of the pressure sensor 18 is consistent with the pressure in the bag, it means If there is no leakage of gas in the soft infusion bag 8, it can be determined that the soft infusion bag 8 is not damaged, that is, the heat sealing strength is qualified; It has been damaged, that is, the heat sealing strength is not enough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com