Multi-level anoxic-aerobic series-connection biochemical pool and method for denitrifying tannery wastewater with same

The technology of biochemical pool and aerobic pool is applied in the field of multi-stage anoxic and aerobic serial biochemical pool and its denitrification of tannery wastewater. , incomplete denitrification and other problems, to achieve the effect of inhibiting growth and reproduction, conducive to promotion and implementation, and conducive to growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

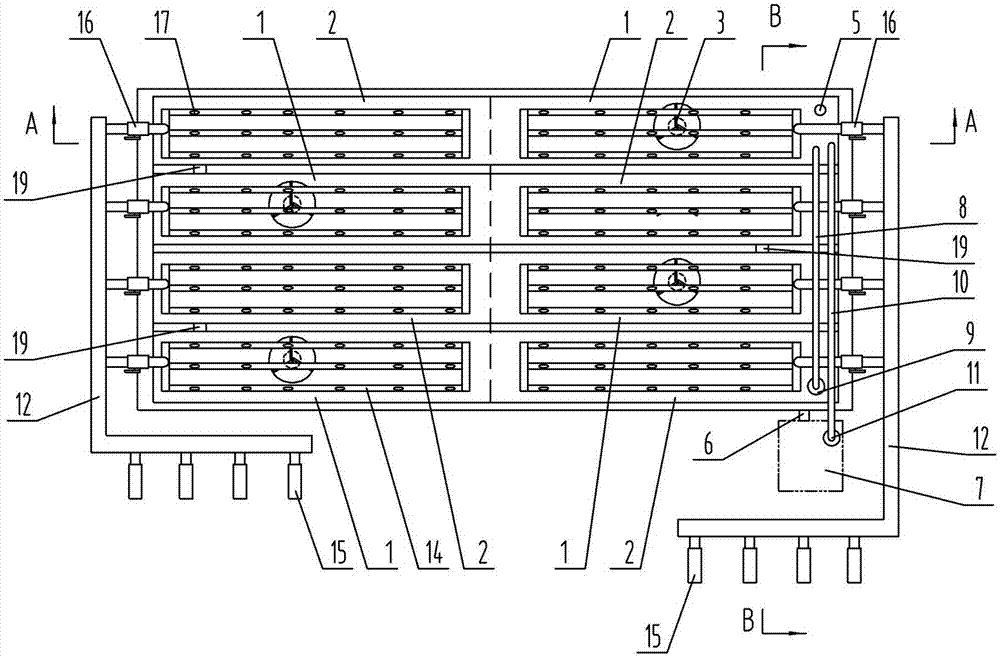

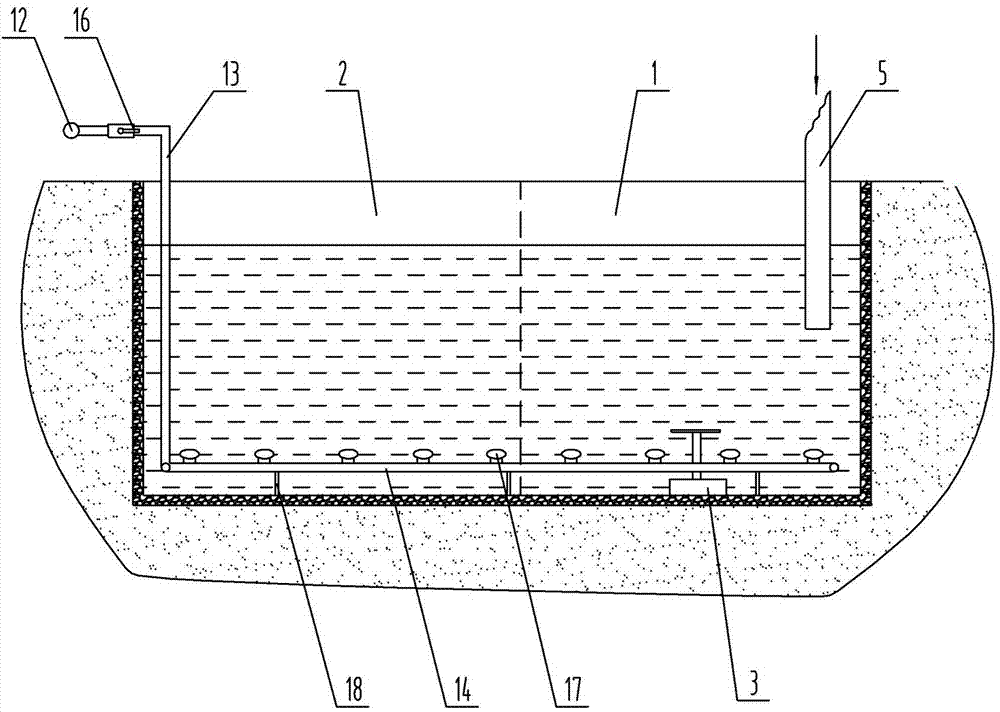

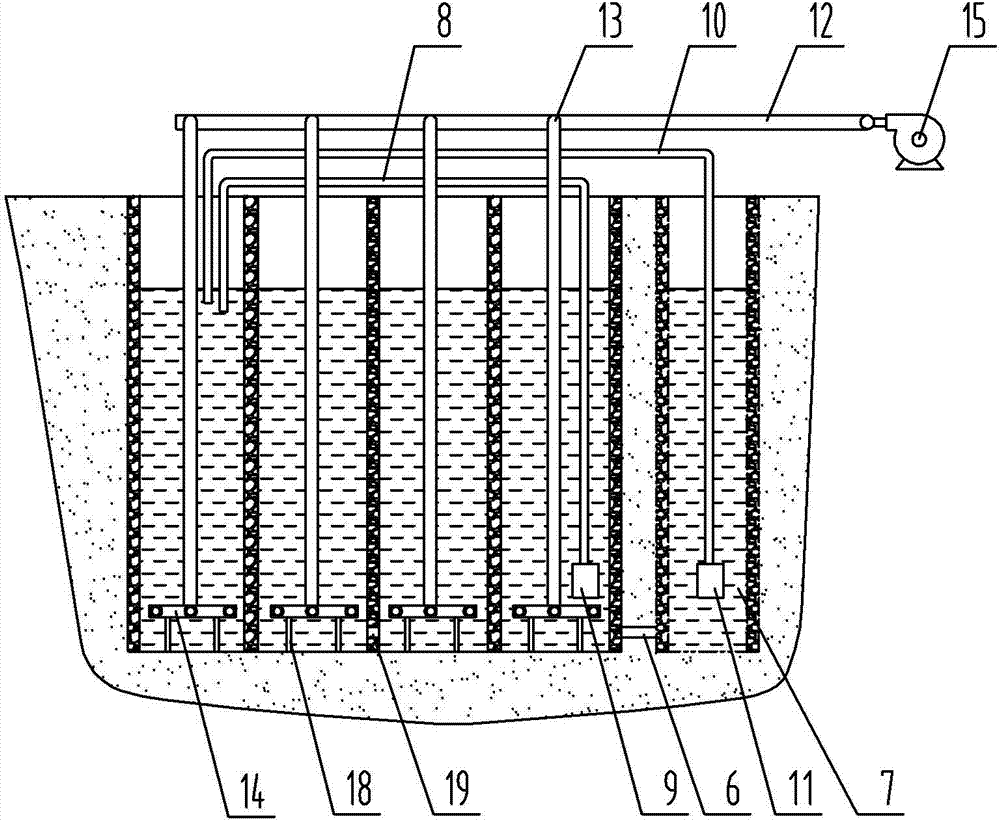

[0034] see Figure 1 to Figure 4 , in the figure, the multistage anoxic and aerobic series biochemical pool of the present invention is divided into a plurality of strip pools in the biochemical pool, and each strip pool is divided into anoxic pool area 1 and aerobic pool area 2, wherein in the anoxic At least one submersible mixer 3 is installed in the pool area, and a set of aeration pipeline systems with control valves are respectively installed in the anoxic pool area and the aerobic pool area to control the dissolution of different anoxic pool areas and aerobic pool areas. Oxygen content, the anoxic pool area and the aerobic pool area are multi-stage series pool areas, a communication hole 19 is provided between the aerobic pool area of the upper level and the anoxic pool area of the lower level, and the primary anoxic pool area A water inlet pipe 5 is provided on the pool area, and an outlet pipe 6 is provided on the final aerobic pool area. The outlet pipe communica...

Embodiment 2

[0039] The method for denitrification of tannery wastewater by using multi-stage anoxic-aerobic series biochemical pools in Example 1 includes four-stage series-connected anoxic and aerobic treatment, specifically comprising the following steps:

[0040] (1) Pass the wastewater into the multi-stage anoxic and aerobic biochemical pools in series, mix with the activated sludge in the pools, and control the aeration of the biochemical pools at all levels to make the dissolved oxygen reach: the first level anoxic pool area 0~0.3 mg / L, 0.3~0.7 mg / L in the aerobic pool area, 0.2~0.5 mg / L in the second anoxic pool area, 0.5~1.0 mg / L in the aerobic pool area, and the third anoxic pool area 0.3~0.5 mg / L, 0.5~1.2 mg / L in the aerobic pool area, 0.3~2.0 mg / L in the fourth anoxic pool area, 2.0~3.0 mg / L in the aerobic pool area; the control residence time is 48h, the activity The sludge settlement ratio of SV30 is 40%.

[0041] (2) Pass the upper nitrification treatment solution in the fi...

Embodiment 3

[0044] The method for denitrification of tannery wastewater by using multi-stage anoxic-aerobic series biochemical pools in Example 1 includes four-stage series-connected anoxic and aerobic treatment, specifically comprising the following steps:

[0045] (1) Pass the wastewater into the multi-stage anoxic and aerobic biochemical pools in series, mix with the activated sludge in the pools, and control the aeration of the biochemical pools at all levels to make the dissolved oxygen reach: the first level anoxic pool area 0~0.3 mg / L, 0.3~0.7 mg / L in the aerobic pool area, 0.2~0.5 mg / L in the second anoxic pool area, 0.5~1.0 mg / L in the aerobic pool area, and the third anoxic pool area 0.3~0.5 mg / L, 0.5~1.2 mg / L in the aerobic pool area, 0.3~2.0 mg / L in the fourth anoxic pool area, 2.0~3.0 mg / L in the aerobic pool area; the control residence time is 44h, the activity The sludge settlement ratio of SV30 is 43%.

[0046] (2) Pass the upper nitrification treatment liquid in the fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com