Calcium removing equipment and process in cobalt wet metallurgy process

A technology of hydrometallurgy and equipment, which is applied in the field of calcium removal equipment and technology in the process of cobalt hydrometallurgy, can solve the problems of high saponification rate of P204, and achieve the effects of good extraction effect, high removal degree, and low operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

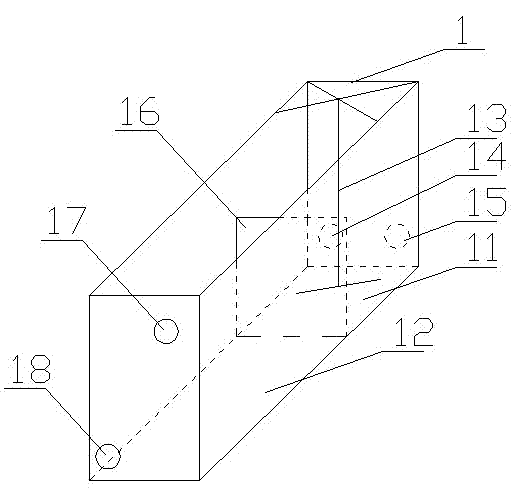

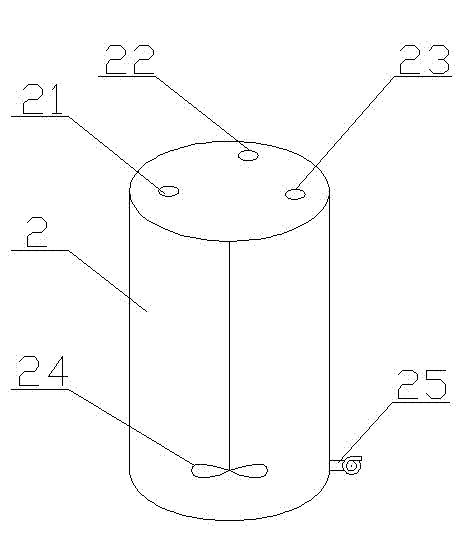

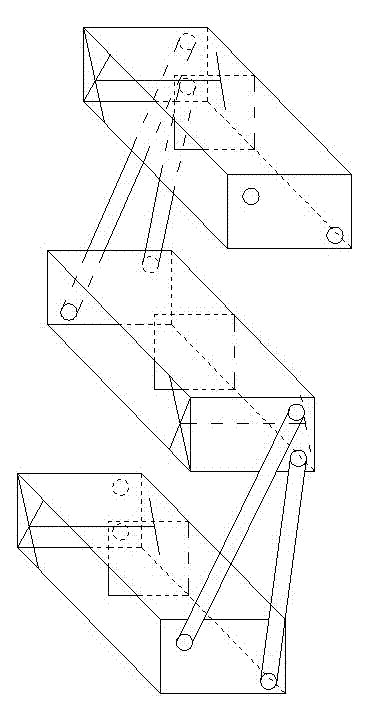

[0029] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

[0030] As shown in the figure, a decalcification device in cobalt hydrometallurgy process includes an extraction tank and an alkali adjustment stirring tank 2 . The extraction tank includes thirty stages of extraction tanks 1 connected in series, and the extraction tank 1 includes a mixing chamber 11, a clarification chamber 12, a stirring paddle 13, an organic inlet 14, an aqueous phase inlet 15, a dividing plate 16, an organic outlet 17 and Aqueous phase outlet 18. The mixing chamber 11 in the extraction tank 1 and the clarification chamber 12 are arranged in parallel perpendicular to the series direction of the extraction tanks, and a partition 16 is provided between the mixing chamber 11 and the clarification chamber 12, and the height of the partition 16 is lower than that of the extraction tank 1. height, the solution in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com