A kind of ionic liquid extraction resin and its preparation and application method

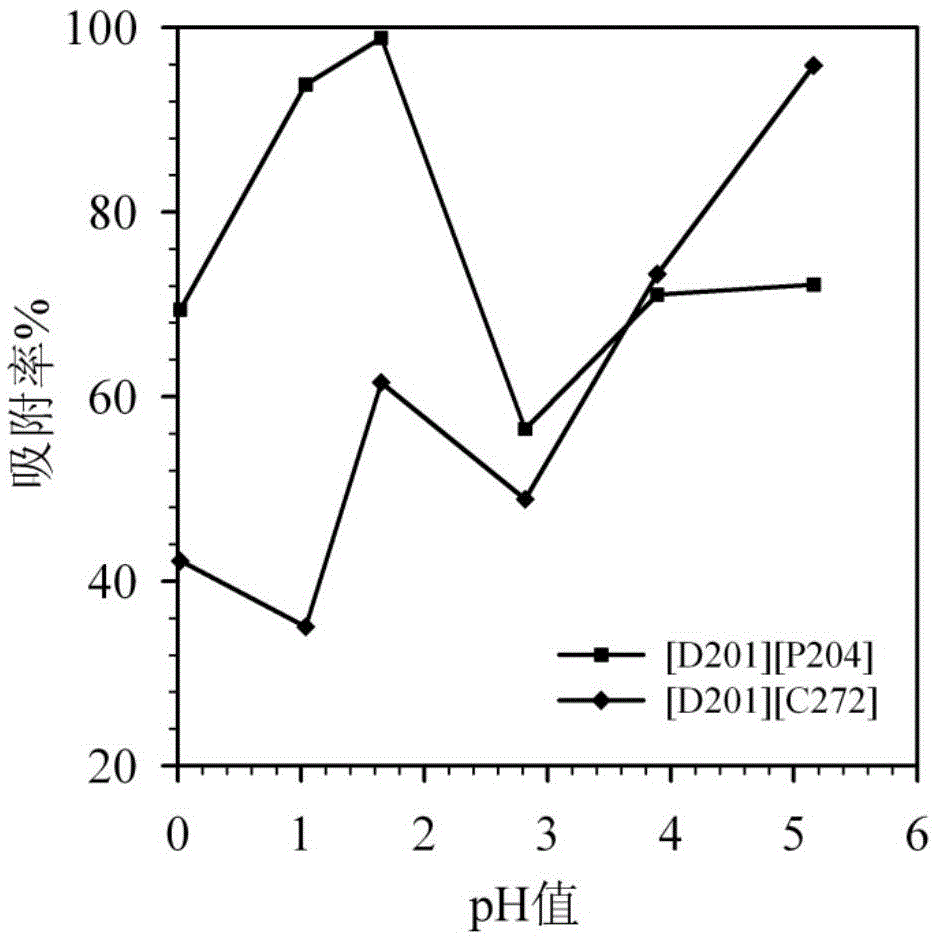

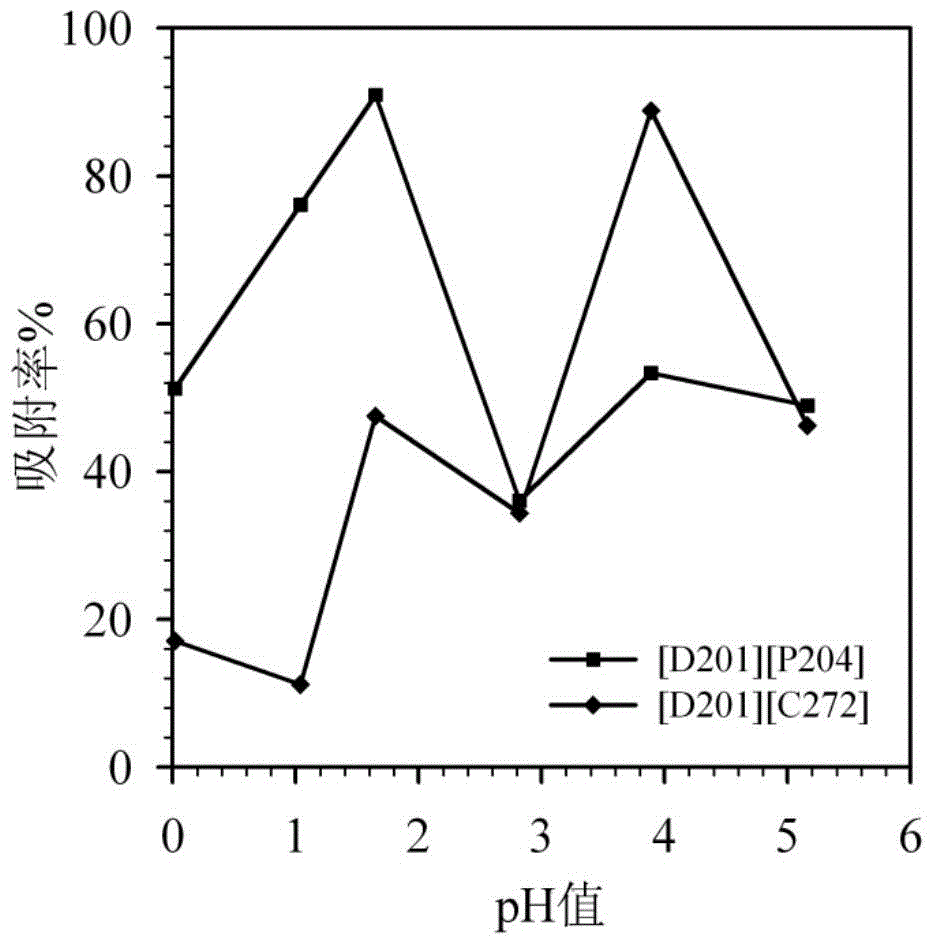

A technology of extraction resin and ionic liquid, which is applied in the field of ionic liquid extraction resin for the efficient recovery of rare earths, can solve the problems of poor stability and single function of the extraction agent, and achieve high adsorption rate and adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

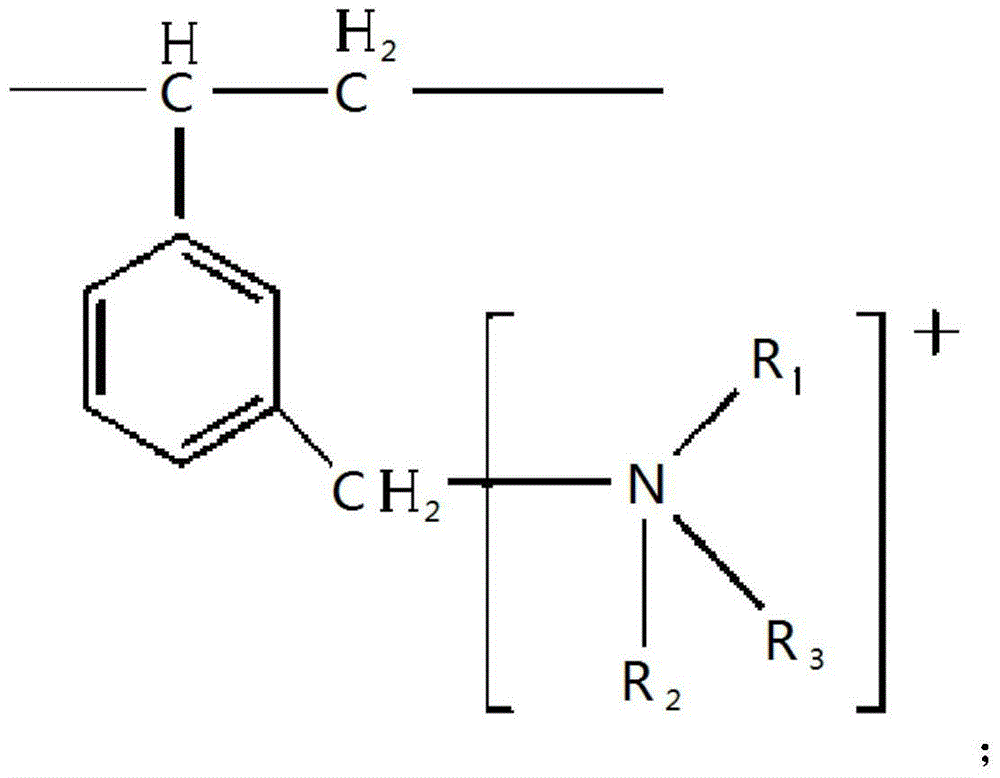

[0035] (1) Wash the strong base styrene resin (chlorine type) with 2% (wt) hydrochloric acid solution and 2% (wt) sodium hydroxide solution respectively, and wash repeatedly with deionized water until the pH value of the effluent liquid is neutral , and finally use sodium hydroxide solution and resin to stir and react at room temperature, the pH value of the deionized water washing solution is neutral, filter, and dry at 20°C to obtain a strong base styrene resin of the hydroxide type; the chlorine The volume ratio of type strong alkali styrene resin to hydrochloric acid and sodium hydroxide solution is 1:1;

[0036] (2) Disperse the hydroxide type strong base styrene resin obtained in step (1) into N,N-dimethylformamide, swell at room temperature for 0.5h, then add bis-(2,4,4-tris Methylpentyl)phosphonic acid (Cyanex272), after fully reacting for 6h, filter out the resin, wash the resin with absolute ethanol, and dry at 20°C to obtain the ionic liquid extraction resin modifie...

preparation Embodiment 2

[0039] (1) Wash the strong base styrene resin (chlorine type) with 4% (wt) hydrochloric acid solution and 4% (wt) sodium hydroxide solution respectively, and wash repeatedly with deionized water until the pH value of the effluent liquid is neutral , and finally use sodium hydroxide solution and resin to stir and react at room temperature, the pH value of the deionized water washing solution is neutral, filter, and dry at 50°C to obtain a strong base styrene resin of the hydroxide type; the chlorine The volume ratio of type strong base styrene resin to hydrochloric acid and sodium hydroxide solution is 1:4;

[0040] (2) Disperse the hydroxide-type strong base styrene resin obtained in step (1) into N,N-dimethylformamide, swell for 2 hours at room temperature, and then add bis-(2,4,4-trimethyl Amylpentyl)phosphonic acid (Cyanex272). After fully reacting for 12h, the resin was filtered out, washed with absolute ethanol, and dried at 50°C to obtain the ionic liquid extraction resi...

preparation Embodiment 3

[0043] (1) Wash the strong base styrene resin (chlorine type) with 3% (wt) hydrochloric acid solution and 3% (wt) sodium hydroxide solution respectively, and wash repeatedly with deionized water until the pH value of the effluent liquid is neutral , and finally use sodium hydroxide solution and resin to stir and react at room temperature, the pH value of the deionized water washing solution is neutral, filter, and dry at 40°C to obtain a strong base styrene resin of the hydroxide type; the chlorine The volume ratio of type strong base styrene resin to hydrochloric acid and sodium hydroxide solution is 1:2;

[0044](2) Disperse the hydroxide-type strong base styrene resin obtained in step (1) into N,N-dimethylformamide, swell at room temperature for 6 hours, and then add bis-(2,4,4-trimethyl Amylpentyl)phosphonic acid (Cyanex272). After fully reacting for 21h, the resin was filtered out, washed with absolute ethanol, and dried at 40°C to obtain the ionic liquid extraction resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com