Construction method of hollow anchor rod grouting through double ball valve connecting pipe

A technology of connecting pipes and double ball valves, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of grouting backflow or long construction period, and achieve the problems of insufficient grouting, simple equipment and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

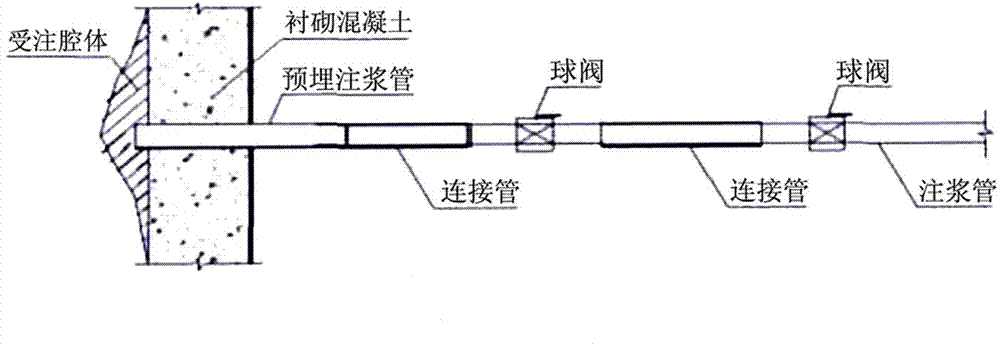

[0026] The principle of the construction method of the present invention is to inject (press) the grout into the injected cavity through a relatively large pressure. In order to avoid the grout backflow in the injected cavity caused by unloading when the grouting is terminated, the ball valve at the tail end is closed first when the grouting is stopped. , then turn off the grouting pump, and finally remove the pipeline between the two ball valves, and remove the left ball valve after the initial setting of the grout. In this way, a good grouting reinforcement effect has been obtained, and the problem of grout backflow and insufficient filling of the injection cavity when the vault grouting is stopped in the past has been avoided.

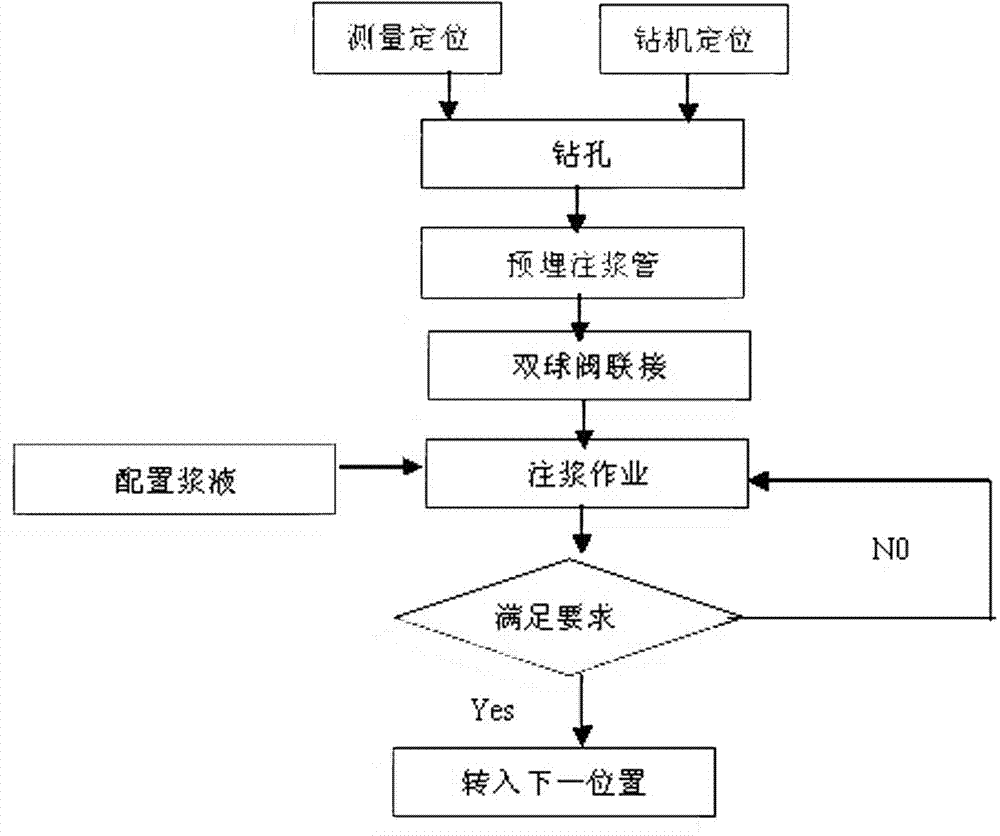

[0027] The casing wall water flushing method is used to drill the holes, and the layout is different according to the size of the void area. The drilling depth should reach the grouting consolidation section. Records should be made during the drillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com