High-pressure air supply valve with pressure difference control function and air scavenging method

A technology of high-pressure air and control functions, which is applied in the direction of valve lift, valve details, valve devices, etc., can solve the problem that the main valve cannot adjust the blowing air supply flow, etc., to avoid excessive blowing flow, compact structure, and maintainability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The main technical index of this invention is as follows:

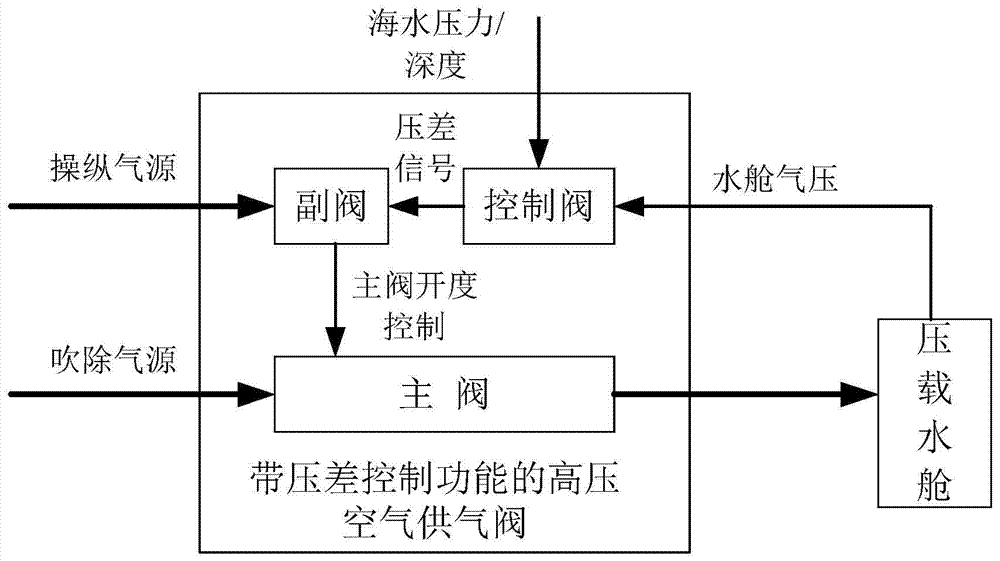

[0039] figure 1 It is the working flow diagram of the high-pressure air supply valve with differential pressure control function of the present invention. The high-pressure air supply valve with differential pressure control function is composed of three parts: main valve, auxiliary valve and control valve. The main valve is the main channel for high-pressure air supply, and the auxiliary valve is used for the opening and closing operation of the main valve. The control valve controls the air supply volume of the main valve by sensing the pressure difference between the ballast water tank and the seawater outside the ship.

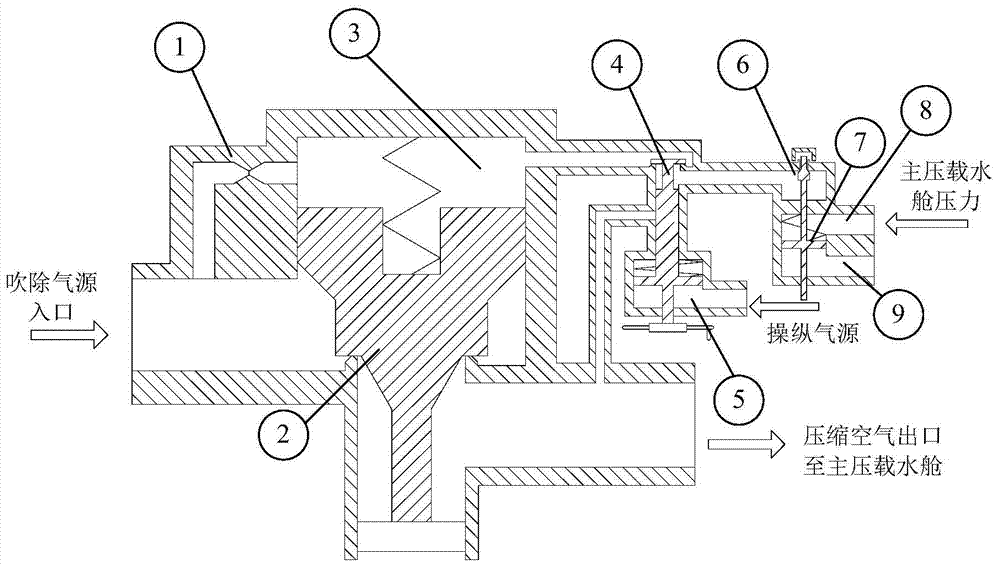

[0040] figure 2 It is a schematic diagram of the structure of the high-pressure air supply valve with differential pressure control function of the present invention, which is composed of three parts: the main valve, the auxiliary valve and the control valve; the main valve includes the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com