Pipe-jacking construction method for small-diameter pipes

A construction method and small-diameter technology, applied in pipeline laying and maintenance, drilling equipment and methods, pipes/pipe joints/pipe fittings, etc., can solve problems that do not meet construction needs, affect traffic, damage roads, etc., and improve planning The effect of design and construction level, low comprehensive cost and accelerated construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

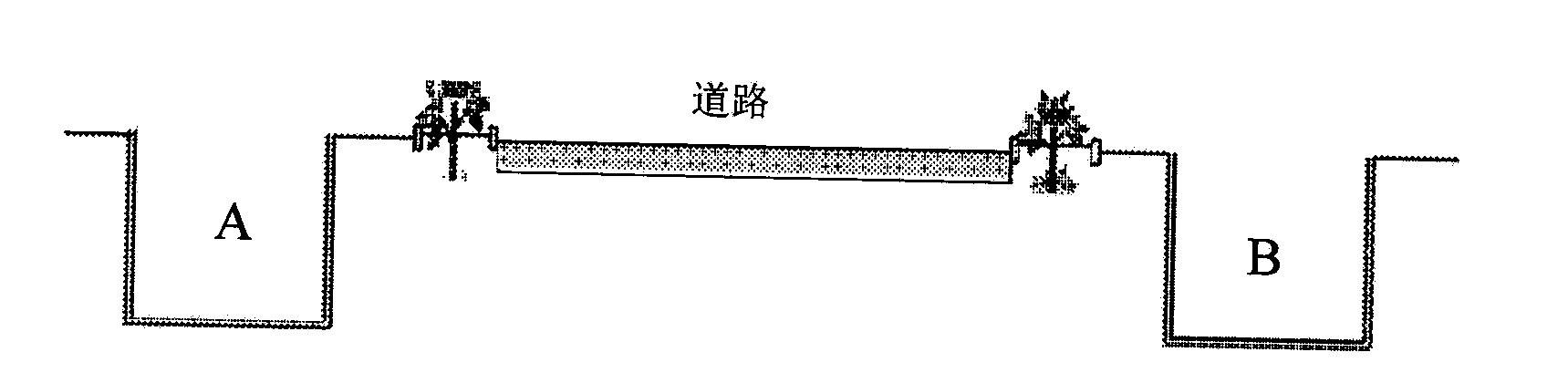

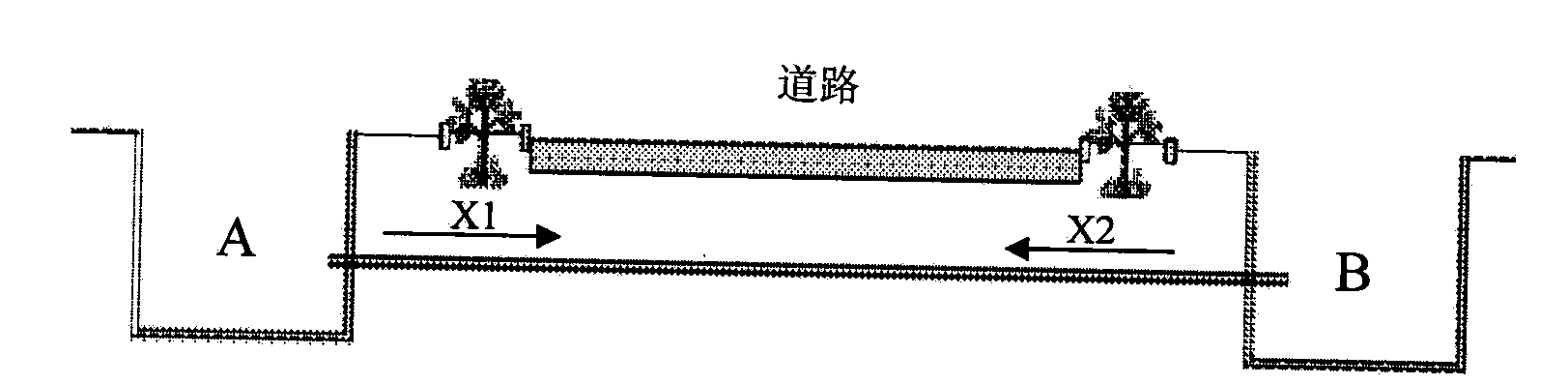

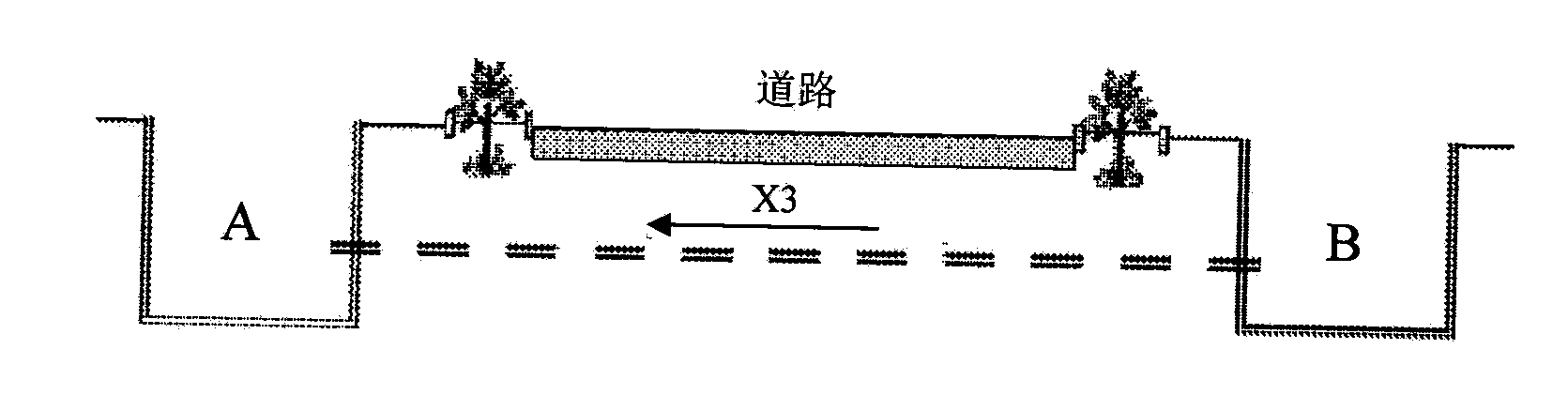

[0027] first refer to Figure 1 to Figure 3 A diagram showing the main stages of the pipe jacking construction of the small diameter pipeline of the present invention, figure 1 The first phase diagram shown includes working well and receiving well construction, drilling rig installation; figure 2 The second stage diagram shown includes drilling and reaming; and image 3 The diagram of the third stage shown includes hot-melt welding and pipe drawing; in the figure, A is the working well, B is the receiving well, figure 2 The X1 direction is the drilling direction, and the X2 direction is the reaming direction; image 3 The X3 direction in the figure is the direction of pulling the tube.

[0028] refer to Image 6 The detailed flowchart of the pipe jacking construction method for small-diameter pipelines of the present invention is shown, and the construction process steps are: measuring and setting out → making working wells and receiving wells → installing pipe jacking e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com