Spraying gun self-sealing tube base device for flue system

A flue system, self-sealing technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as poor sealing effect, waste of manpower and time, inconvenient installation and disassembly, etc., to prevent the outflow of smoke , Apply efficient, easy to adjust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

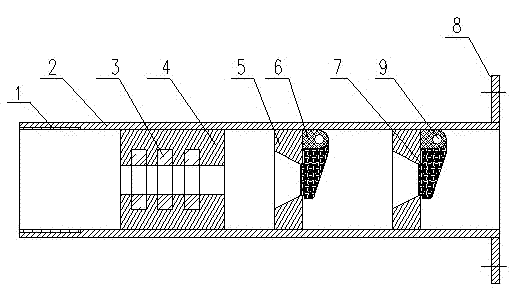

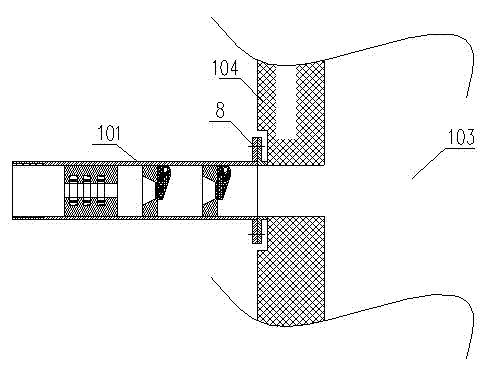

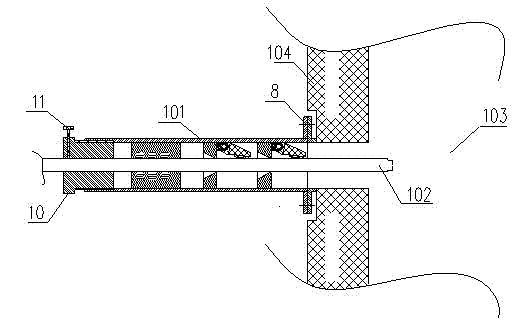

[0035] Such as figure 1 , figure 2 , image 3 As shown, the spray gun base 101 is included, the front end of the spray gun base 101 is fixed to the insulation layer 104 of the flue 103 , and the spray gun 102 enters from the rear end of the spray gun base 101 . The spray gun base 101 is connected with the insulation layer 104 of the flue 103 through the flange 8 . There are three levels of sealing mechanism in the pipe seat, the first level is threaded connection, the second level is effective connection through sealing gasket, and the third level is through double-level cover plate sealing plug connection, the specific structure is as follows:

[0036] The third stage sealing mechanism: the front end of the spray gun tube seat 101 is provided with a plug support 5 sealed and fixed to its inner wall, and the middle part of the plug support 5 is provided with a through hole 2 for the spray gun 102 to pass through. The side of the head support 5 near the flue is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com