A liquid level signal conversion device for exhausted shutdown

A signal conversion, exhaustion shutdown technology, applied in the direction of the liquid level indicator for physical variable measurement, etc., can solve the problem of erroneous shutdown signal, flight failure, unreliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

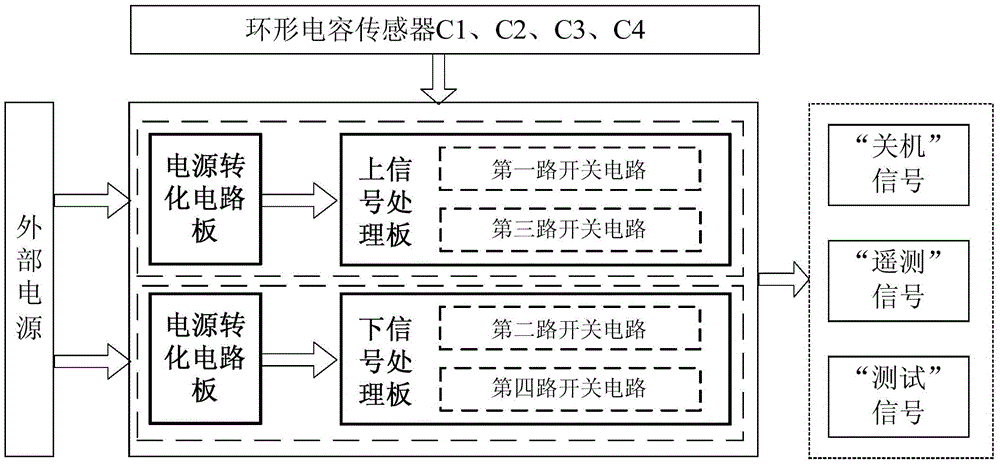

[0035] Such as figure 1 As shown, the present invention includes an annular capacitive sensor C1, an annular capacitive sensor C2, an annular capacitive sensor C3, an annular capacitive sensor C4, a housing 1, two power conversion circuit boards 2, an upper signal processing circuit board 3, and a lower signal processing circuit board 4.

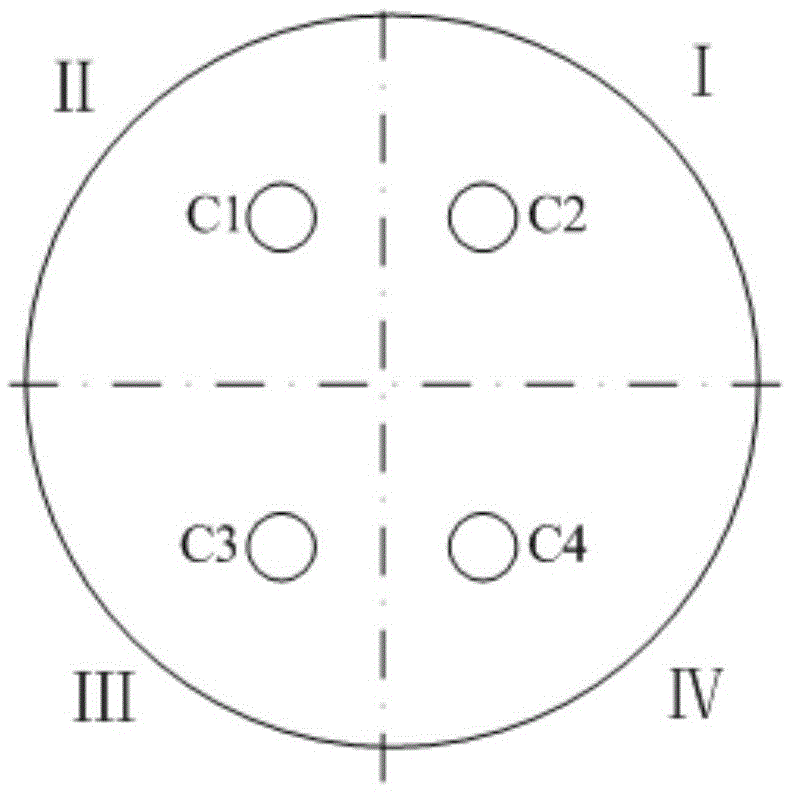

[0036] Such as figure 2 As shown, four ring-shaped capacitive sensors C1, C2, C3, and C4 are respectively located in four quadrants of the same horizontal plane in the liquid storage tank; ring-shaped capacitive sensor C1 and ring-shaped capacitive sensor C2 are symmetrical to the symmetry axis of the second quadrant and the first quadrant Installation; the annular capacitive sensor C3 and the annular capacitive sensor C4 are installed symmetrically with respect to the symmetry axes of the third quadrant and the fourth quadrant.

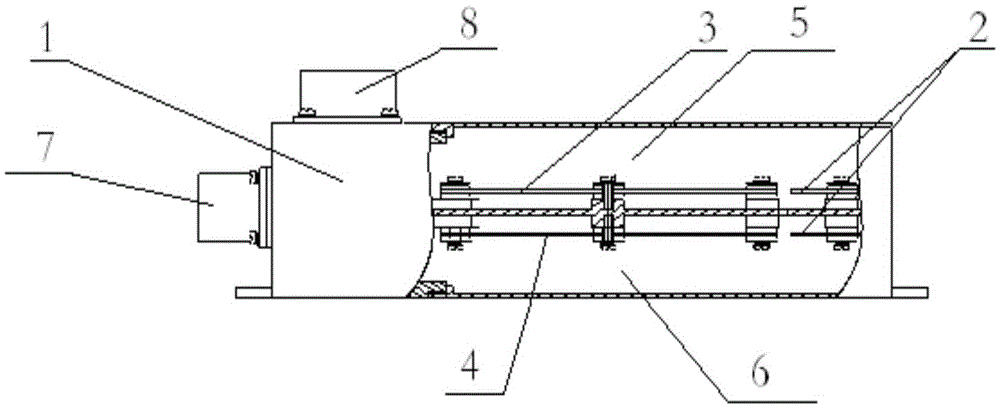

[0037] Such as Figure 3-4As shown, the housing 1 of the present invention is located outside the liquid sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com