A Control System Structure for Functional Adjustment of Photolithography Projection Objective Lens

A technology of lithography projection and control system, which is applied to microlithography exposure equipment, photolithographic process exposure devices, etc., can solve the problems of long adjustment time, affecting imaging quality, and the inability of capacitive sensors to perform long-distance transmission, so as to improve the realization of Efficiency, the effect of shortening the adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

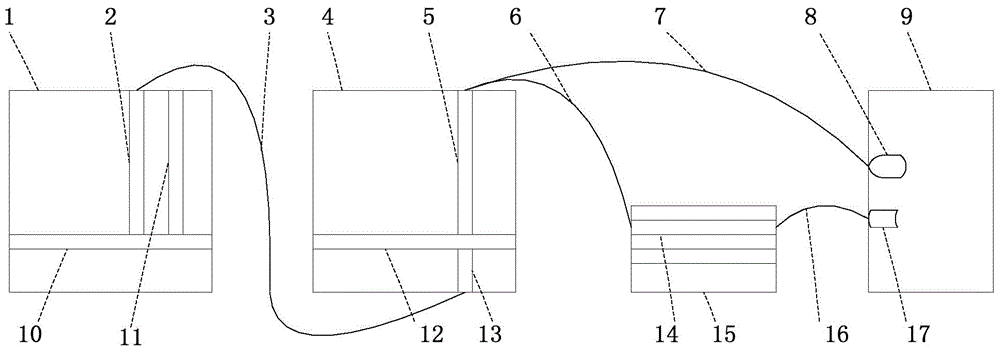

[0018] See attached figure 1 , the structure of a control system for functional adjustment of a lithographic projection objective lens of the present invention includes a control cabinet 1, a power amplifier cabinet 4, a level conversion cabinet 15, a piezoelectric driver 8 and a capacitive sensor 17;

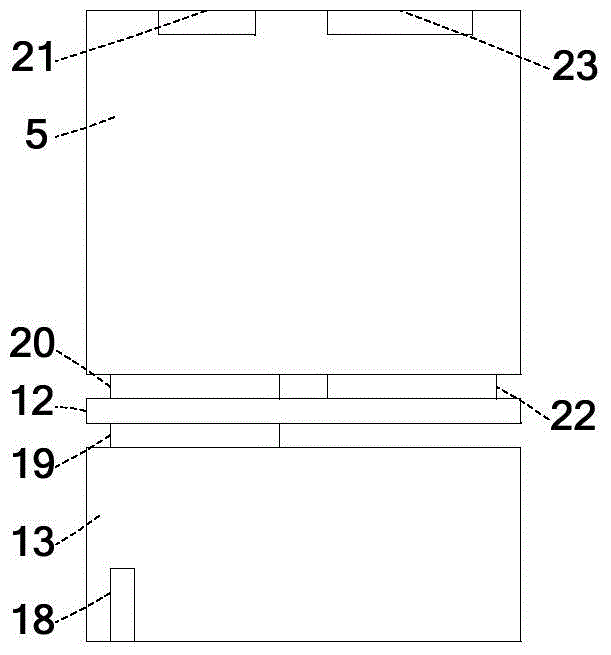

[0019] The control cabinet 1 includes a standard VME backplane 10, a main control board 11 and an optical fiber communication board 2, and the main control board 11 and the optical fiber communication board 2 are inserted on the standard VME backplane 10, so The power amplifier chassis 4 includes a non-standard VME backplane 12, a core algorithm board 13 and a drive acquisition board 5, and the core algorithm board 13 and the drive acquisition board 5 are inserted on the non-standard VME backplane 12, The analog-to-digital conversion board 14 is included...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com