Genetic algorithm optimized fuzzy PID flow control method in variable-rate spraying system

A spray system and genetic algorithm technology, applied in the field of genetic algorithm optimization fuzzy PID control flow, can solve the problems of different spray droplet sizes, poor stability, uneven droplet distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

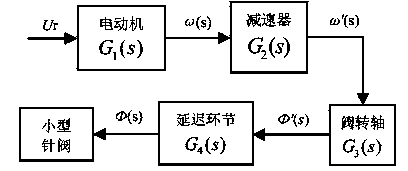

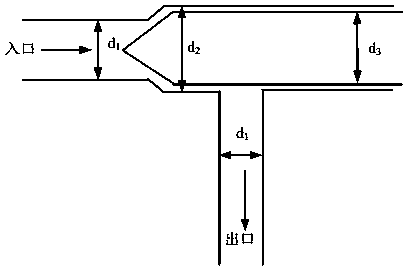

[0028] The flow control valve is composed of a motor, a reducer, a valve shaft, a small needle valve and a delay link of the system, such as figure 1 shown. The small needle valve is connected to the infusion tube through an input port and an output port, which has high control precision and is suitable for the control of small flow. Its simplified structure is as follows: figure 2 shown.

[0029] DC motor S221D uses the first-order inertia link fitting approximation method to measure its transfer function, assuming that the initial state is zero, the motor speed is ω, and the operating voltage of the motor is U r , the transfer function of the DC motor is

[0030] G 1 (s)=[ω(s)] / [U r (s)] = [K 1 (s)] / (Ts+1) (1)

[0031] In the formula, K 1 =28.95 is the gain of the DC motor; T=1.93(s) is the time constant of the DC motor.

[0032] The shaft of the DC motor is connected through the shaft of the reducer, the speed after deceleration is ω(s), and the output ω′(s)=K 2 ω...

Embodiment 2

[0045] Fuzzy controller design:

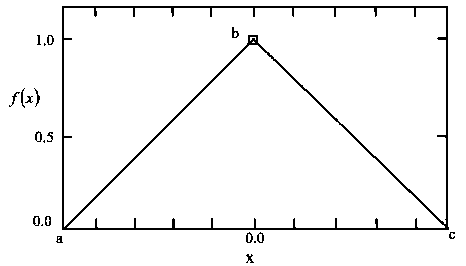

[0046] The fuzzy controller adopts the triangle as the membership function, and chooses the Mamdani type reasoning method. As shown in figure (3)

[0047] Shown, the parameters (a, b, c) determine the shape of the triangle, that is, the membership function f(x).

[0048] The fuzzy control rules are shown in Table 1:

[0049] Table 1 Fuzzy control rule table

[0050]

[0051] u in the table 11 -u 33 Both represent the state of the motor, and the value is one of 1 (negative large), 2 (zero), and 3 (positive large).

Embodiment 3

[0053] Genetic algorithm optimization fuzzy controller design:

[0054] First: determine the objective function

[0055] In order to improve the quickness and stability of the system response, the rise time, overshoot and cumulative error of the system are used as the indicators. Here, in order to achieve the purpose of saving energy and spraying pesticides, the penalty function is used, and the overshoot is used as the optimal control. One of the indicators, then its objective function (that is, the fitness function) is shown in formulas (6) and (7).

[0056] (6)

[0057] (7)

[0058] where e(t), u(t), t u are system error, control output and rise time respectively; W 1 , W 2 , W 3 , W 4 Indicates the weight. Therefore, the objective function is closely related to the requirements of the system, here we can change the weight W 1 , W 2 , W 3 , W 4 To make the output meet the target. Here, in order to improve the response time and precision of the system, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com