Sparking plug of gasoline engine

A technology for an internal combustion engine and a spark plug, which is applied in the field of spark plugs for gasoline internal combustion engines, can solve the problems of weak flashover intensity, influence on combustion effect, dispersion of electric sparks, etc., and achieve the effects of improving combustion efficiency, reliable ignition and fuel saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

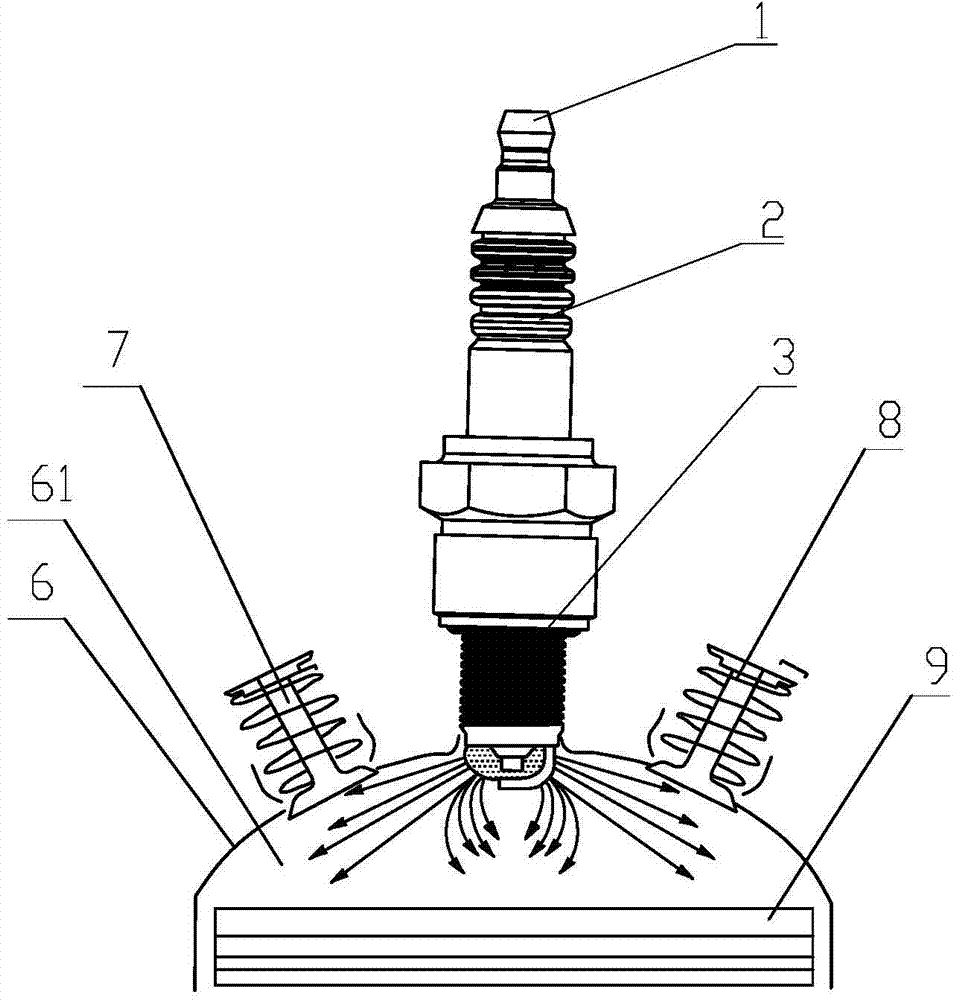

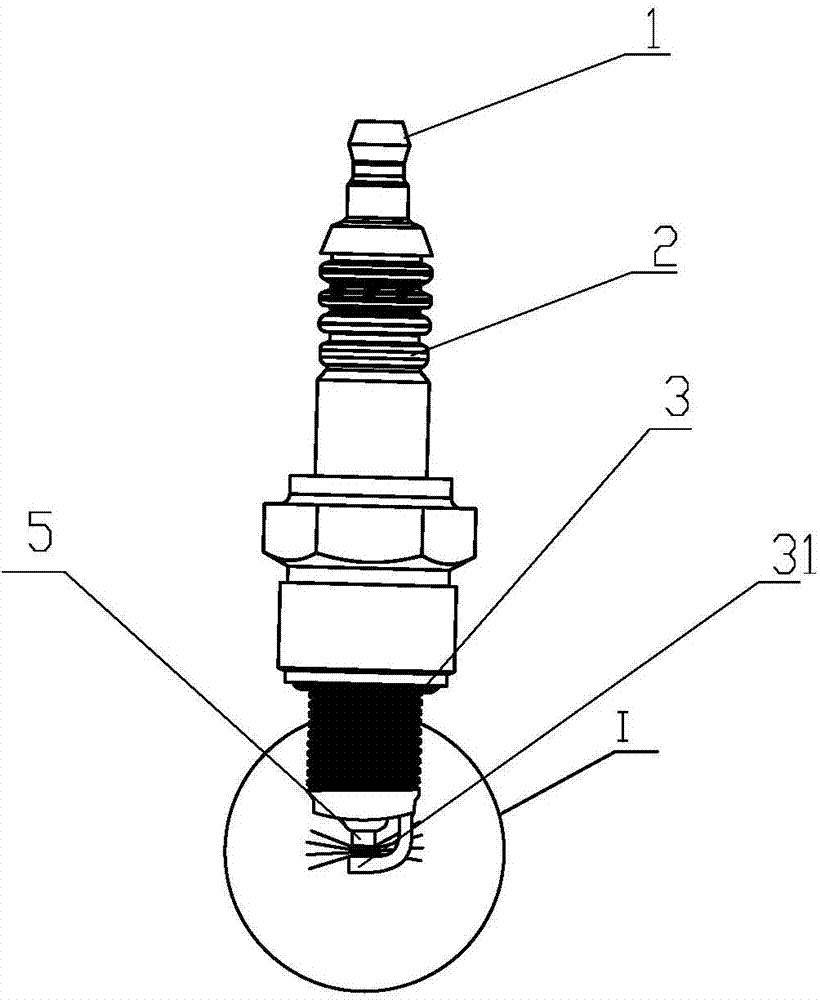

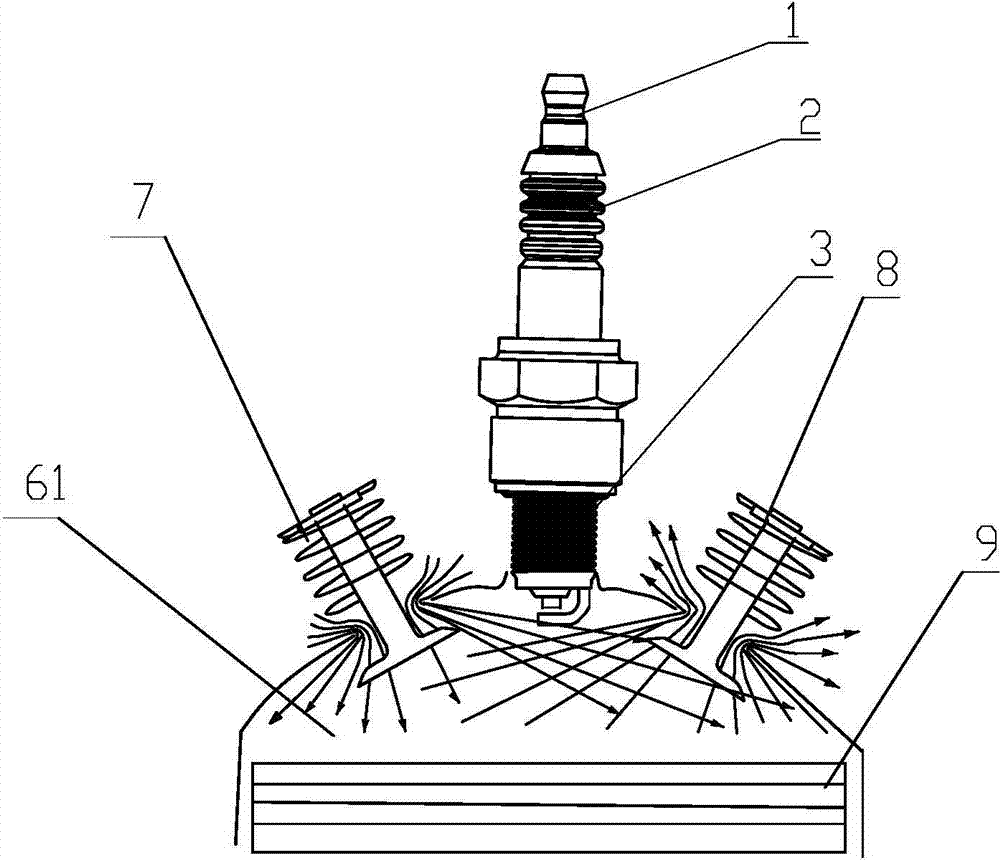

[0019] Example: such as figure 1 As shown, the gasoline internal combustion engine spark plug is still provided with a high-voltage electric nut 1, an insulating ceramic body 2, a ground wire with a hexagonal cap and a threaded iron body 3, and the high-voltage electric nut 1 protrudes from the end of the insulating porcelain body 2 , the high-voltage electric lead-out pole 5 is exposed from the center of the ground iron body 3 at the other end, and there is an insulating layer 4 between the high-voltage electric lead-out pole 5 and the inner wall of the ground iron body 3, and the insulating layer 4 is higher than the end surface of the ground iron body 3, and the height The output part is about 0.3~3.5 times of its own diameter, depending on the specifications of the spark plug, usually 1.0-1.5 times is better, the high voltage electric lead-out pole 5 is higher than the end face of the insulating layer 4, and the higher part is about its diameter. 0.3~3.5 times of its own ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com