Hydraulically-loaded dual-power pulverizer

A hydraulic loading, dual power technology, applied in grain processing and other directions, can solve the problems of convenient manufacturing, high temperature of the grinding head spindle and grinding head bearing, and inconvenient maintenance, and achieves increased stability, equipment safety and stable operation. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

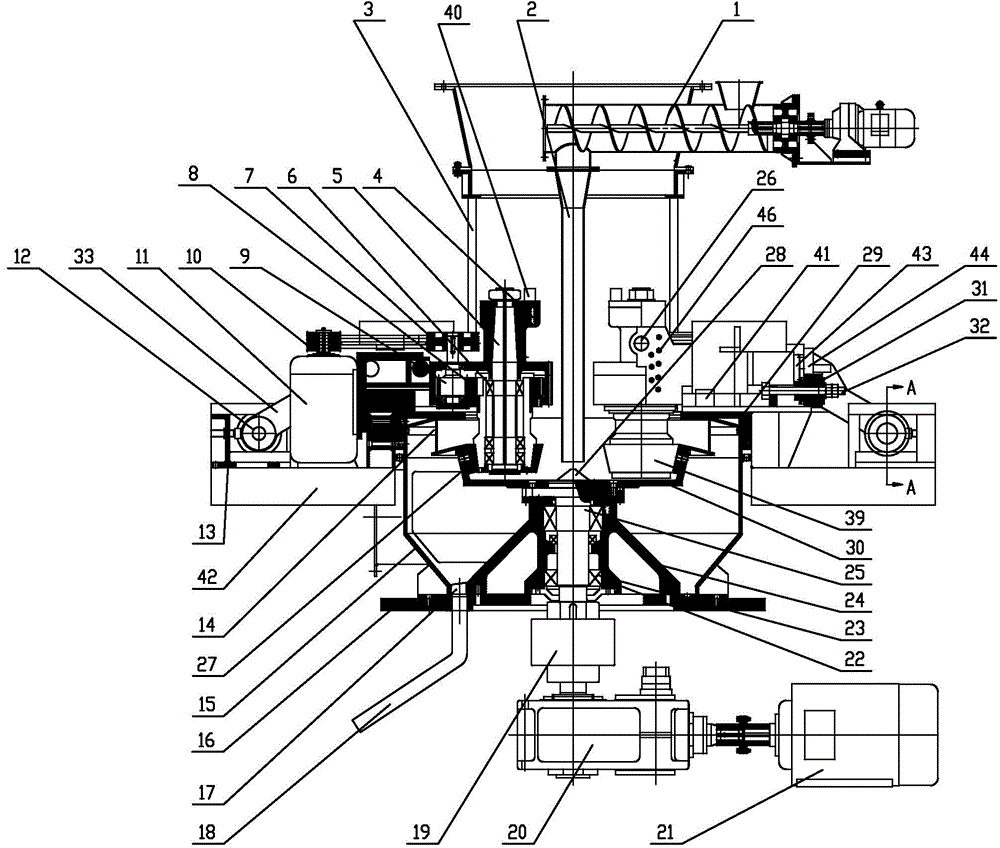

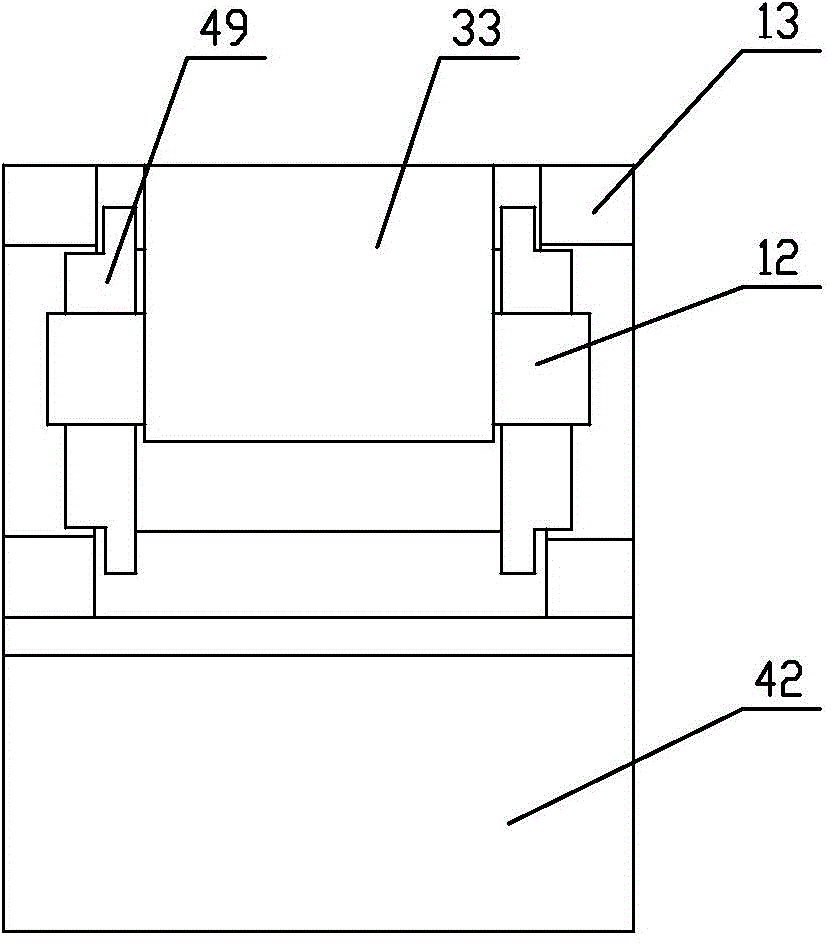

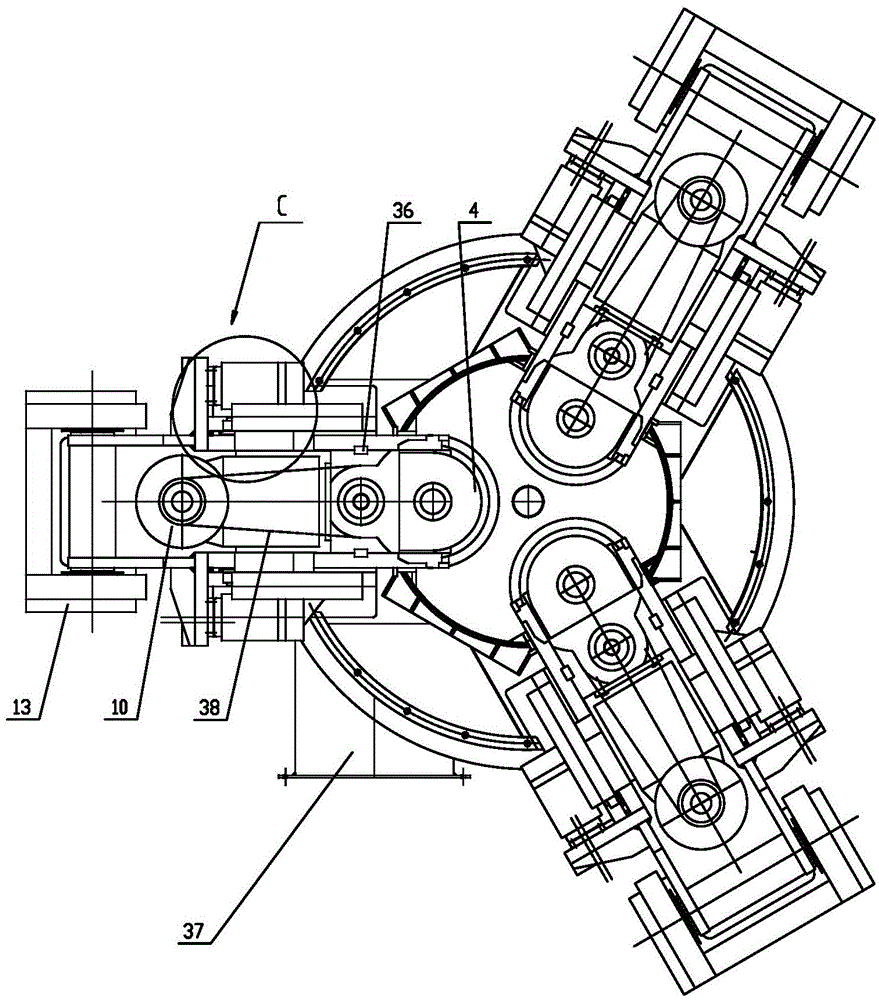

[0037] Such as Figure 1 to Figure 3 The present invention is composed of upper body 3, lower body 15 and base plate 16 to form a closed body. The upper end of the upper body 3 is connected to the classifier, and a feeding device consisting of a feeding screw 1 and a feeding pipe 2 is installed on the side. The periphery of the lower part of the upper body is radially and evenly distributed with three saddles 29, the top of the saddle 29 is provided with a step, the lower plane 53 of the step is fixedly equipped with a guide block 48, and the bottom of the swing arm body 33 is provided with two pairs of swing arm body rollers 34, The swing arm body roller 34 can slide in the groove formed by the step facade 52 and the guide block 48, on the guide block 48 top, a briquetting block 47 is arranged near the swing arm body roller 34 side, and the briquetting block 47 and the guide block 48 are together Constrains the movement direction of the swing arm body.

[0038]The front end...

Embodiment 2

[0052] The difference between this preferred embodiment and preferred embodiment 1 is that in this preferred embodiment, the number of grinding head bodies 4 is not limited, and it is necessary not to interfere between the equipment. The swing arm body roller 34 is arranged on the side of the swing arm body 33. Swing arm body roller 34 is three pairs, four pairs, five pairs or six pairs.

[0053] The specific working method is the same as that of the first preferred embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com