Full-automatic plate shearing machine hydraulic system on basis of PLC control

A hydraulic system and shearing machine technology, applied in shearing equipment, shearing devices, manufacturing tools, etc., can solve the problems of high energy consumption, low production efficiency, low degree of automation, etc., and achieve low energy consumption and energy reduction. Consumption, excellent quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

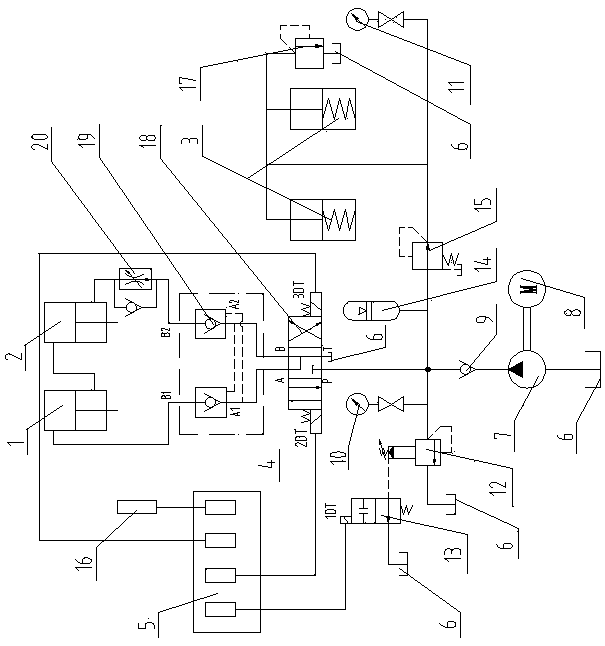

[0012] Such as figure 1 As shown, the present invention mainly includes the same first and second shear cylinders 1 and 2, two identical press cylinders 3, a hydraulic control system 4 and a PLC control system 5 for the shear cylinder and the press cylinder.

[0013] The hydraulic control system 4 of the shearing cylinder and the pressing cylinder includes an oil tank 6, a hydraulic pump 7, a motor 8, a one-way valve 9, a first pressure gauge 10, a second pressure gauge 11, a pilot relief valve 12, a two-position two Through solenoid valve 13, accumulator 14, pressure reducing valve 15, travel switch 16, overflow valve 17, one-way speed regulating valve 20, two-position four-way solenoid valve 18 and double hydraulic control one-way valve 19.

[0014] The motor 8 is connected to the hydraulic pump 7, the oil inlet of the hydraulic pump 7 is connected to the oil tank 6, the oil inlet of the check valve 9 is connected to the oil outlet of the hydraulic pump 7, and the oil inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com