Jig special for laser welding

A special fixture and laser welding technology, which is applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of affecting the access of protective gas, hindering filling, and large volume, and achieve the effect of facilitating the aggregation of light spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

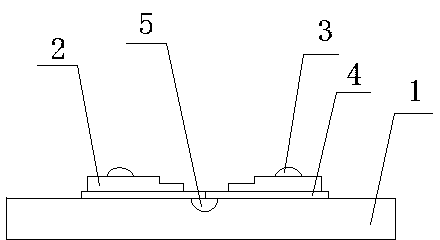

[0011] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings. A special fixture for laser welding is provided with a base plate 1, and a shielding gas groove 5 with a circular arc-shaped cross section is provided on the base plate 1 for passing in Protective gas to obtain a protective atmosphere, its cross-section is set in a circular arc shape, which is convenient for cleaning the welding slag inside after long-term use. The substrate 1 is also provided with a splint 2 for fixing the material 4 to be welded on it, and the splint 2 passes through The fixing screw 3 is detachably fixed on the base plate 1. For this, threaded holes that can cooperate with the fixing screws can be provided on the splint 2 and the base plate 1 to facilitate the fixing and disassembly of the splint 2. The splint 2 on the base plate 1 should be provided with However, it should be noted that the end of the splint 2 close to the shiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com