Monitoring system for thermal error of machine tool spindle

A monitoring system, a thermal error technology, applied in measurement/indication equipment, metal processing mechanical parts, metal processing equipment, etc., can solve problems affecting fault detection, can not meet the high precision and real-time measurement requirements of thermal deformation measurement of machine tool spindles, temperature measurement Point wiring difficulties and other problems, to achieve the effect of fast response, wireless transmission and processing, and improved monitoring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

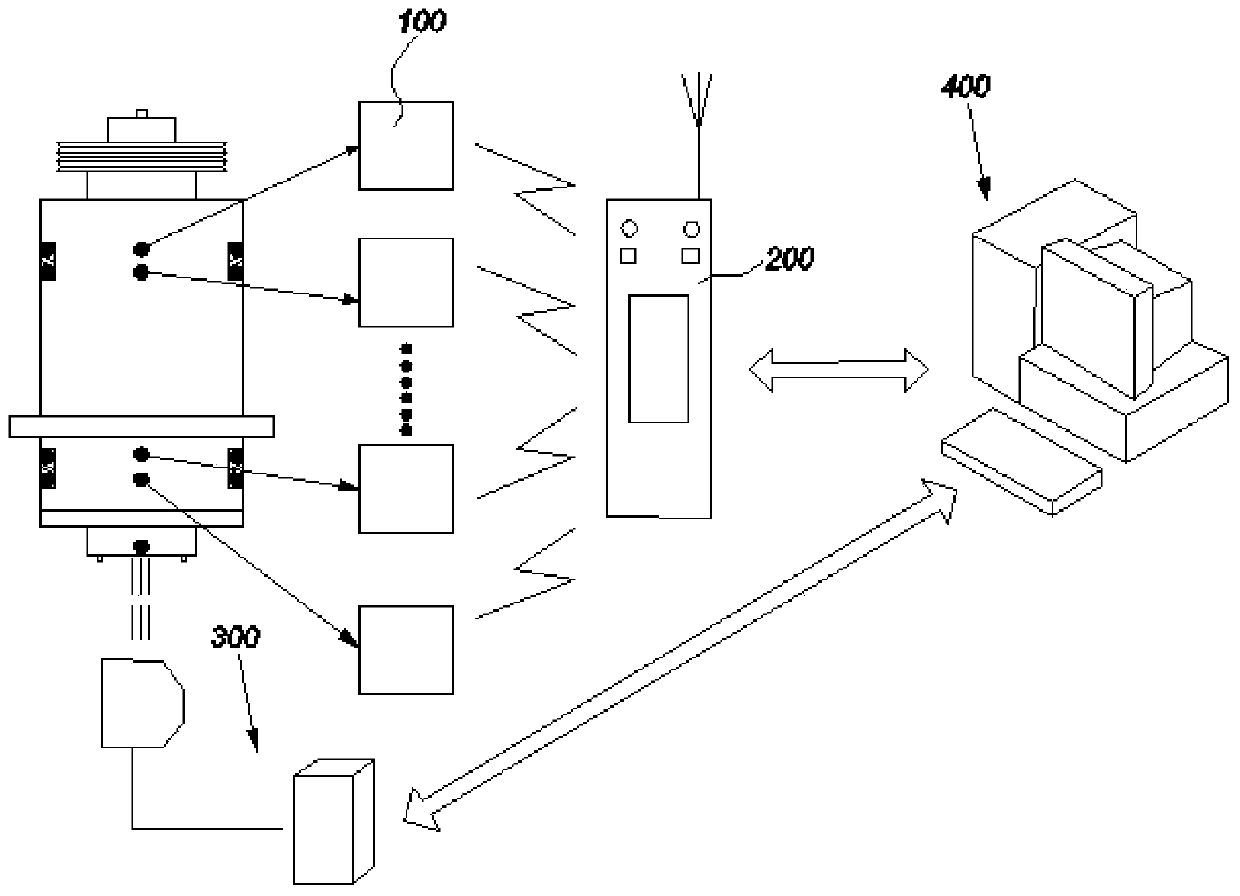

[0024] figure 1 A thermal error monitoring system for a machine tool spindle according to an embodiment of the present invention is schematically shown.

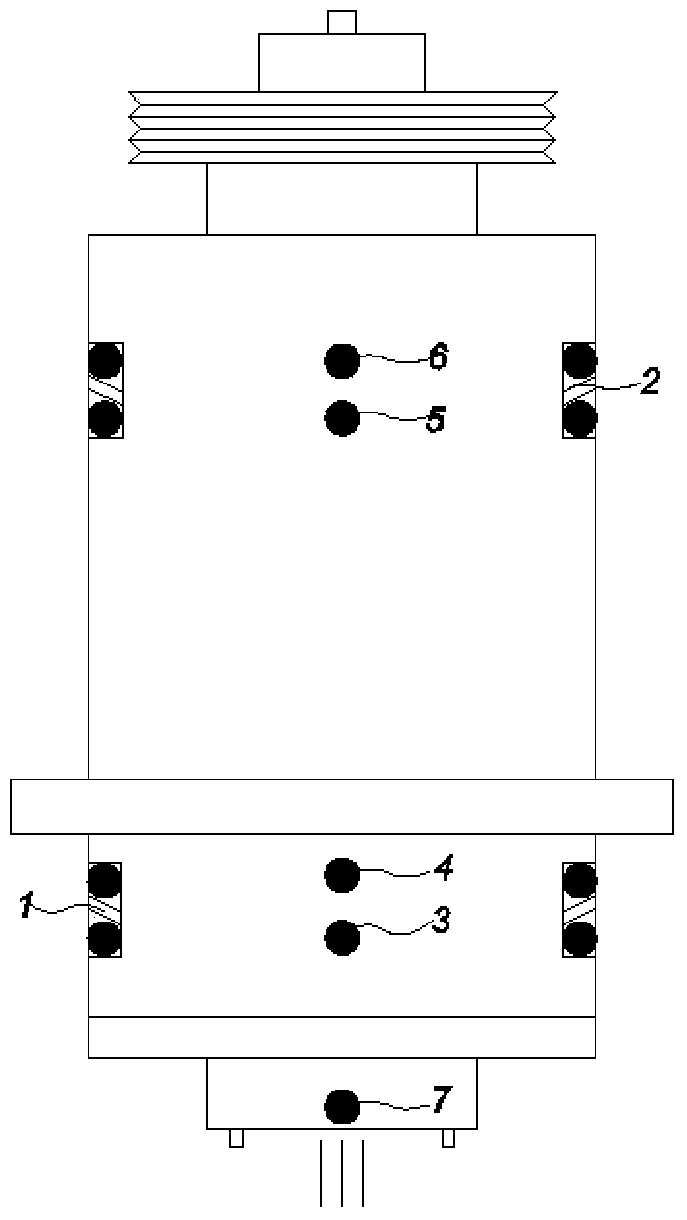

[0025] Such as figure 1 As shown, it is a vertical machining center spindle thermal error monitoring system, including a temperature sensing tag 100, an RFID reader 200, a laser displacement sensor testing system 300, a host computer control system 400, a temperature sensing tag 100 and an RFID reader 200 communicate wirelessly, the RFID reader 200 is connected to the host computer control system 400 through the RS232 serial port, and the laser displacement sensor test system 300 is connected to the host computer control system 400 through the USB serial port.

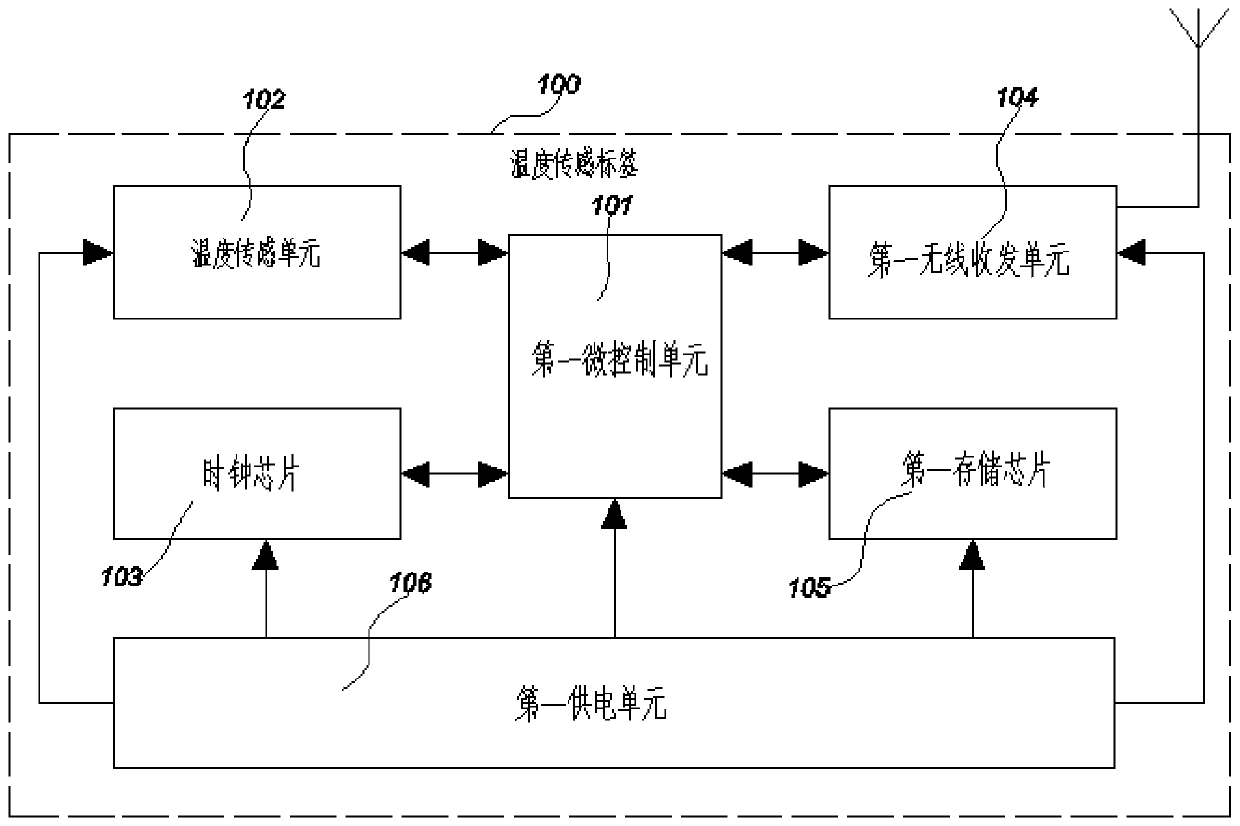

[0026] Such as figure 1 , 3 , 4, and 5, the temperature sensing label 100 includes a first micro control unit 101 (MSP430F149), a temperature s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com