Simulation device and method

A simulation device and process simulation technology, applied in the simulation device and field, can solve problems such as the influence of mold clamping performance, and achieve the effect of rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

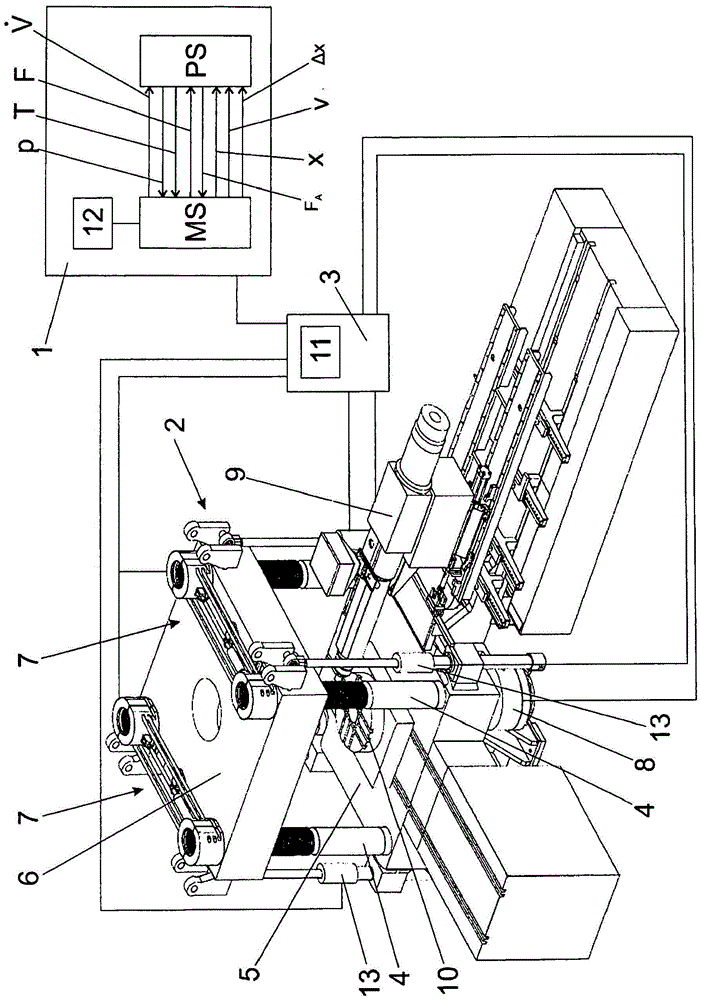

[0026] figure 1 An injection molding machine 2 is shown and its regulating or control unit 3 and simulation device 1 are schematically shown. A vertical clamping unit with vertical bars 4 , a fixed clamping plate 5 and a movable clamping plate 6 is shown here by way of example. Of course, the invention can also be used with any other type of clamping unit. The regulating or control unit 3 is usually connected to all important elements of the injection molding machine 2 . The connections to the rapid stroke cylinder 13 , the locking mechanism 7 , the pressure mechanism 8 and the injection unit 9 are shown here by way of example.

[0027] The clamping unit is shown here in the open state, so that the mold halves of the injection mold 10 are visible.

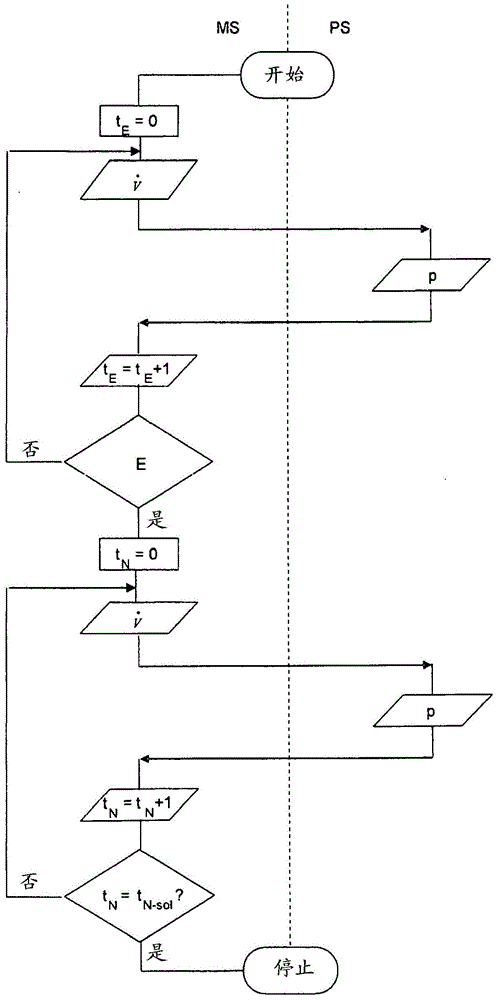

[0028] The machine simulator MS and the process simulator PS are operated in the simulation device 1 , wherein in each simulation step the pressure p calculated by the process simulator PS is transmitted to the machine simulator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com