Pet waste fiber/bamboo fiber reinforced unsaturated polyester composite material and preparation method thereof

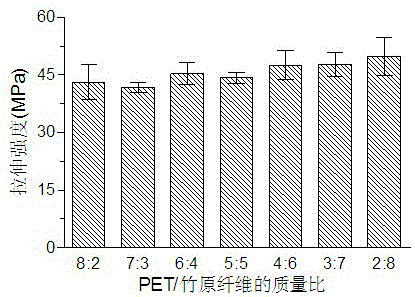

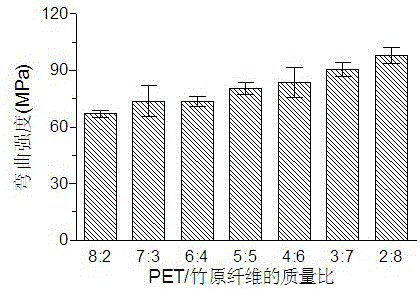

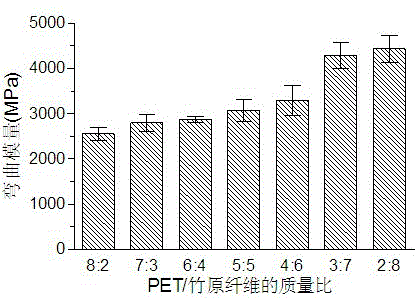

A polyester composite material and bamboo fiber technology, applied in the field of fiber-reinforced resin composite materials, can solve the problems of difficult recycling, low bonding strength, and low mechanical properties of composite materials, and achieve significant economic benefits and social significance, bending strength and The effect of improving the flexural modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Raw materials: raw bamboo fiber is provided by Fujian Haibosi Chemical Technology Co., Ltd.; PET waste fiber is provided by China Energy Conservation Costin New Materials Group Co., Ltd.; unsaturated polyester resin (UPE) is phthalic acid type unsaturated polyester resin (Model: 9231-1TP; viscosity (23°C): 300~550cps; acid value: 18~24mgKOH / g; gelation time: 40~50min; solid content: 57~63%), purchased from Shangwei (Shanghai) Fine Chemical Co., Ltd.; the initiator is methyl ethyl ketone peroxide (MEKP), purchased from Sinopharm Chemical Reagent Co., Ltd.; the accelerator is cobalt naphthenate, purchased from Sinopharm Chemical Reagent Co., Ltd.; the cross-linking agent is styrene, purchased from From Sinopharm Chemical Reagent Co., Ltd. (Wokai).

[0029] PET waste fiber / bamboo fiber composite material:

[0030]Preparation method: Weigh 16g of PET waste fiber and 64g of bamboo fiber and mix them by hand, use a cotton opener to comb into a mixed fiber mat with a width of...

Embodiment 2

[0032] Raw materials: raw bamboo fiber is provided by Fujian Haibosi Chemical Technology Co., Ltd.; PET waste fiber is provided by China Energy Conservation Costin New Materials Group Co., Ltd.; unsaturated polyester resin (UPE) is phthalic acid type unsaturated polyester resin (Model: 9231-1TP; viscosity (23°C): 300~550cps; acid value: 18~24mgKOH / g; gelation time: 40~50min; solid content: 57~63%), purchased from Shangwei (Shanghai) Fine Chemical Co., Ltd.; the initiator is methyl ethyl ketone peroxide (MEKP), purchased from Sinopharm Chemical Reagent Co., Ltd.; the accelerator is cobalt naphthenate, purchased from Sinopharm Chemical Reagent Co., Ltd.; the cross-linking agent is styrene, purchased from From Sinopharm Chemical Reagent Co., Ltd. (Wokai).

[0033] PET waste fiber / bamboo fiber composite material:

[0034] Preparation method: Weigh 40g of PET waste fiber and 40g of bamboo fiber and mix it by hand, then use a cotton opener to comb it into a mixed fiber mat with a w...

Embodiment 3

[0036] Raw materials: raw bamboo fiber is provided by Fujian Haibosi Chemical Technology Co., Ltd.; PET waste fiber is provided by China Energy Conservation Costin New Materials Group Co., Ltd.; unsaturated polyester resin (UPE) is phthalic acid type unsaturated polyester resin (Model: 9231-1TP; viscosity (23°C): 300~550cps; acid value: 18~24mgKOH / g; gelation time: 40~50min; solid content: 57~63%), purchased from Shangwei (Shanghai) Fine Chemical Co., Ltd.; the initiator is methyl ethyl ketone peroxide (MEKP), purchased from Sinopharm Chemical Reagent Co., Ltd.; the accelerator is cobalt naphthenate, purchased from Sinopharm Chemical Reagent Co., Ltd.; the cross-linking agent is styrene, purchased from From Sinopharm Chemical Reagent Co., Ltd. (Wokai).

[0037] Modified PET waste fiber / bamboo fiber composite material:

[0038] Treat bamboo fiber and PET waste fiber with oxygen atmosphere, flow rate of 1.5L / min, power of 30W, and time of 3min, and heat press the treated bamboo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com