A titanium crystal sintering mold

A crystal and mold technology, which is applied in the field of titanium crystal sintering molds, can solve problems such as differences in oxygen content, affecting the purity and quality of the coating layer, and affecting the coating efficiency, so as to improve the purity and quality, shorten the pre-melting time, and shorten the coating time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

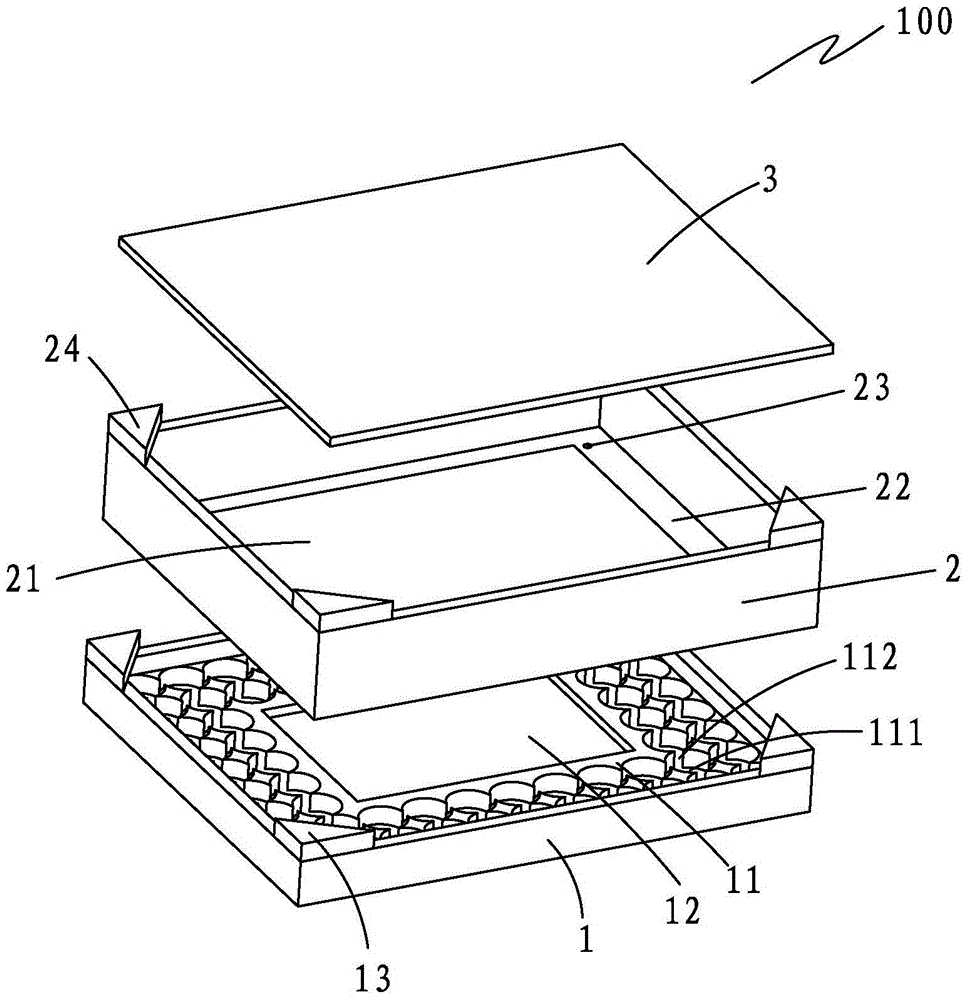

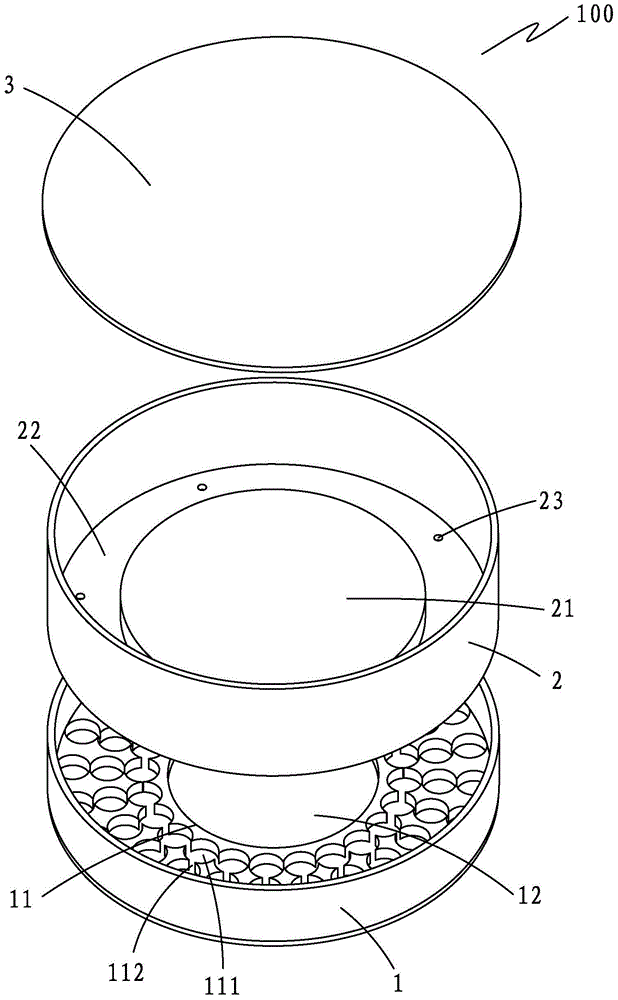

[0015] see figure 1 and figure 2 , a titanium crystal sintering mold 100, comprising a forming mold 1, a crucible 2 placed on the forming mold 1 and a cover plate 3; the forming mold 1 has a cavity 11, and the cavity 11 includes a plurality of The forming die hole 111 that is close to setting, and every adjacent two forming die holes 111 are all provided with a breach portion 112; The cross section of described forming die hole 111 is circular, and the diameter D of this forming die hole 111 is 25mm and a height of 11mm. The setting of the notch 112 is used for the flow of the molten liquid between the forming die holes 111 and the cooling to form a solid product, which is convenient for unloading.

[0016] see again figure 1 and figure 2 , the middle part of the crucible 2 bulges upwards to form a boss 21, and a groove 22 is arranged around the inner wall of the crucible 2 and the boss 21; a plurality of small holes 23 are arranged at intervals on the groove 22 , and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com