A preparation method of thermal non-woven fabric for sanitary napkins

A technology of non-woven fabrics and sanitary napkins, which is applied in the field of thermal non-woven fabric preparation, which can solve the problems of short shelf life of thermal sensitivity of sanitary napkins or panty liners, low utilization rate of functional components, and increased product weight, etc., and achieve good large-scale application The effect of prospect, low cost and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

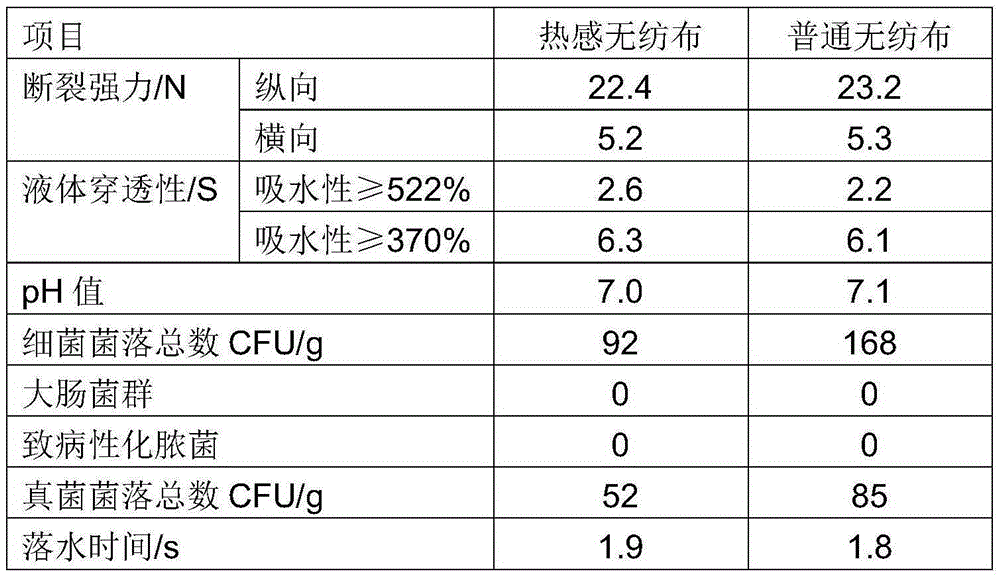

Examples

Embodiment 1

[0013] 1) Prepare heat-sensitive finishing liquid: take vanillyl butyl ether 1% (w / w), triclosan 0.3% (w / w), angelica essential oil 0.2% (w / w), ethanol 25% (w / w) ), hydrogenated castor oil polyoxyethylene ether 7% (w / w), propylene glycol 13.2% (w / w), polyethylene glycol 400 20% (w / w), carboxymethyl cellulose 0.3% (w / w) , water 33% (w / w); the vanillyl butyl ether, triclosan, ethanol, angelica essential oil of the formula quantity are fully mixed to obtain a mixed solution for use; the carboxymethyl cellulose of the formula quantity is added to the formula quantity Mix uniformly in water to obtain a film-forming agent solution for use; add the hydrogenated castor oil polyoxyethylene ether of the formula amount to the above mixed solution and mix uniformly, then add the propylene glycol and polyethylene glycol 400 of the formula amount and mix uniformly, and then add wherein the film-forming agent solution is added and mixed uniformly to obtain a heat-sensitive finishing liquid; ...

Embodiment 2

[0029] 1) Prepare heat-sensitive finishing liquid: take capsaicin 0.5% (w / w), potassium sorbate 0.1% (w / w), angelica essential oil 0.1% (w / w), ethanol 20% (w / w), coconut Oleyl Glyceride 5% (w / w), Propylene Glycol 11% (w / w), Polyethylene Glycol 400 17% (w / w), Polyvinyl Alcohol 0.1% (w / w), Water 46.2% (w / w) w); The capsaicin, potassium sorbate, ethanol, angelica essential oil of formula quantity are fully mixed to obtain mixed solution for stand-by; the polyvinyl alcohol of formula quantity is added to the water of formula quantity and mixed uniformly to obtain film-forming agent solution for stand-by; Add the coco-glyceride of formula quantity to above-mentioned mixed solution and mix homogeneously, then add the propylene glycol of formula quantity and Polyethylene Glycol 400 and mix homogeneously therein, then add described film-forming agent solution wherein and mix homogeneously, promptly obtain heat Sensitive finishing liquid;

[0030] 2) Roll coating and sizing: take the ...

Embodiment 3

[0033] 1) Prepare heat-sensitive finishing liquid: take vanillin butyl ether 2% (w / w), dailongsu 0.5% (w / w), angelica essential oil 0.3% (w / w), ethanol 30% (w / w) ), hydrogenated castor oil ethoxylates 4% (w / w), Tween 203% (w / w), Tween 403% (w / w), propylene glycol 14% (w / w), polyethylene glycol 400 23% (w / w), polyvinylpyrrolidone K30 0.5% (w / w), water 19.7 (w / w); fully mix the formula amount of vanillin butyl ether, dailongsu, ethanol, and angelica essential oil The mixed solution is obtained for use; the polyvinylpyrrolidone K30 of the formula is added to the water of the formula and mixed uniformly to obtain a film-forming agent solution for use; the hydrogenated castor oil polyoxyethylene ether and Tween 20 are added to the above mixed solution. , Tween 40 and mix evenly, then add propylene glycol and polyethylene glycol 400 in the formula amount and mix evenly therein, then add the film-forming agent solution therein and mix evenly, obtain the heat-sensitive finishing solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com