Modular cross-wall structure for civil work

A modular and civil construction technology, applied in the field of civil construction, can solve problems such as low efficiency, difficult to remove accumulated water, and heavy workload, and achieve the effects of flexible construction, increased strength, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

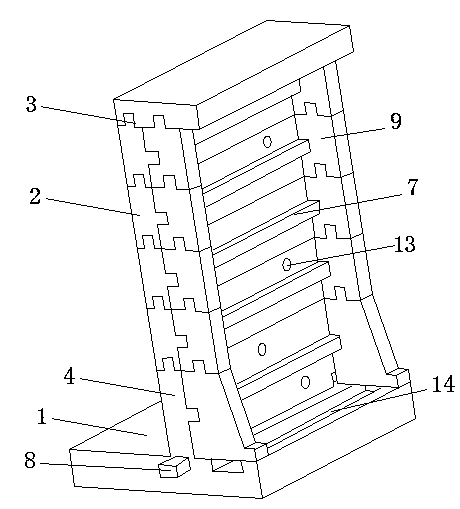

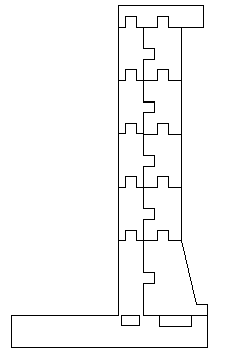

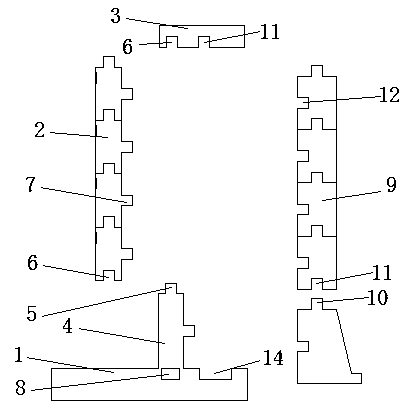

[0024] see figure 1 , figure 2 and image 3 , it can be seen from the figure that the stone sill structure for modular civil engineering proposed by the present invention is composed of several retaining walls spliced from left to right, and each retaining wall is mainly composed of a base 1, a number of adjusting blocks 2 and a cover plate 3, the base 1 is vertically provided with an integrally formed foundation block 4, and the foundation block 4 and the base 1 form an upside-down "T"-shaped structure. Both the upper surface of the basic block 4 and the adjustment block 2 are provided with longitudinal positioning protrusions 5, the lower surface of the adjustment block 2 is provided with a longitudinal positioning groove 6 matching the longitudinal positioning protrusions, and the longitudinal positioning of the lower surface of the upper adjustment b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com