Optical cable GTL (Gas To Liquid) base oil filling paste and preparing method thereof

A technology of base oil and filling paste, applied in the direction of fiber mechanical structure, etc., can solve the problems of stress corrosion, reduce the performance of optical cable information transmission, inconvenience in daily life and work, etc., and achieve the effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

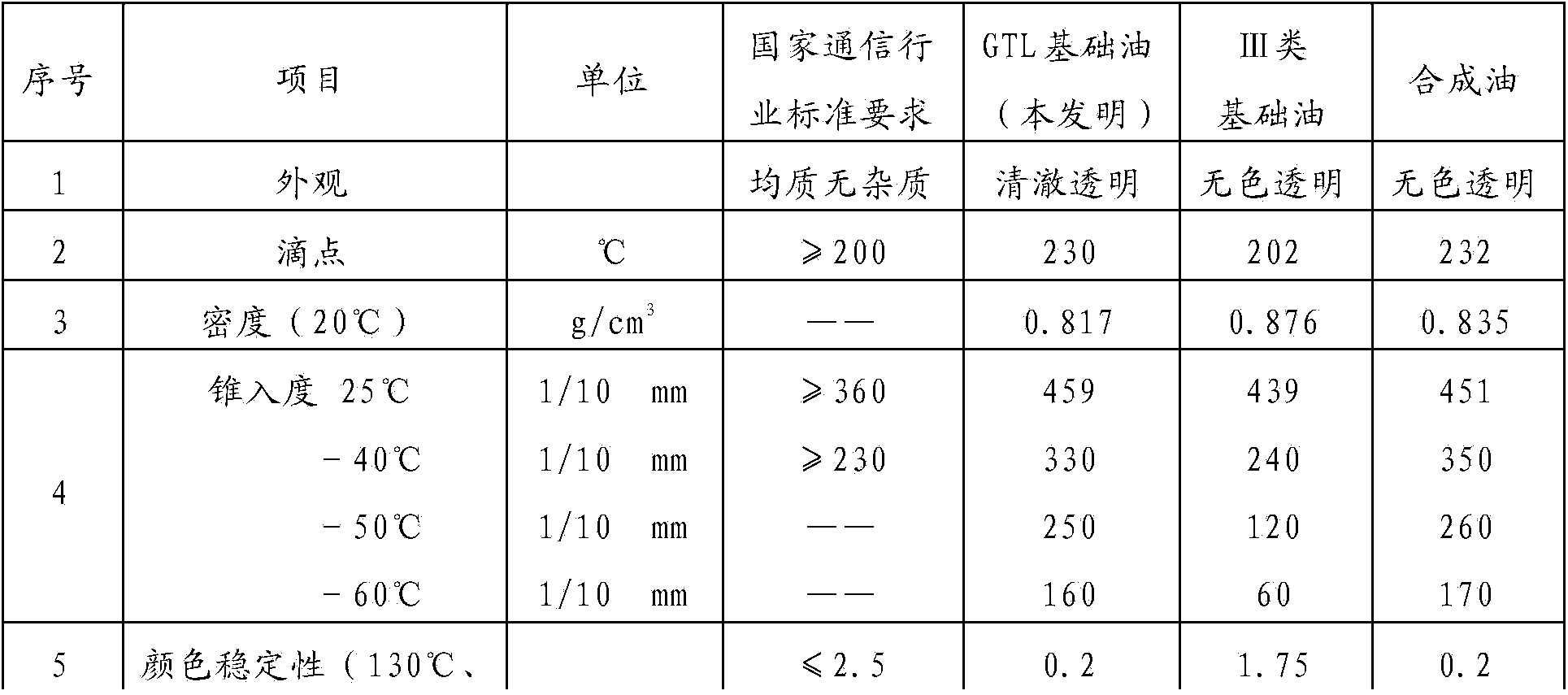

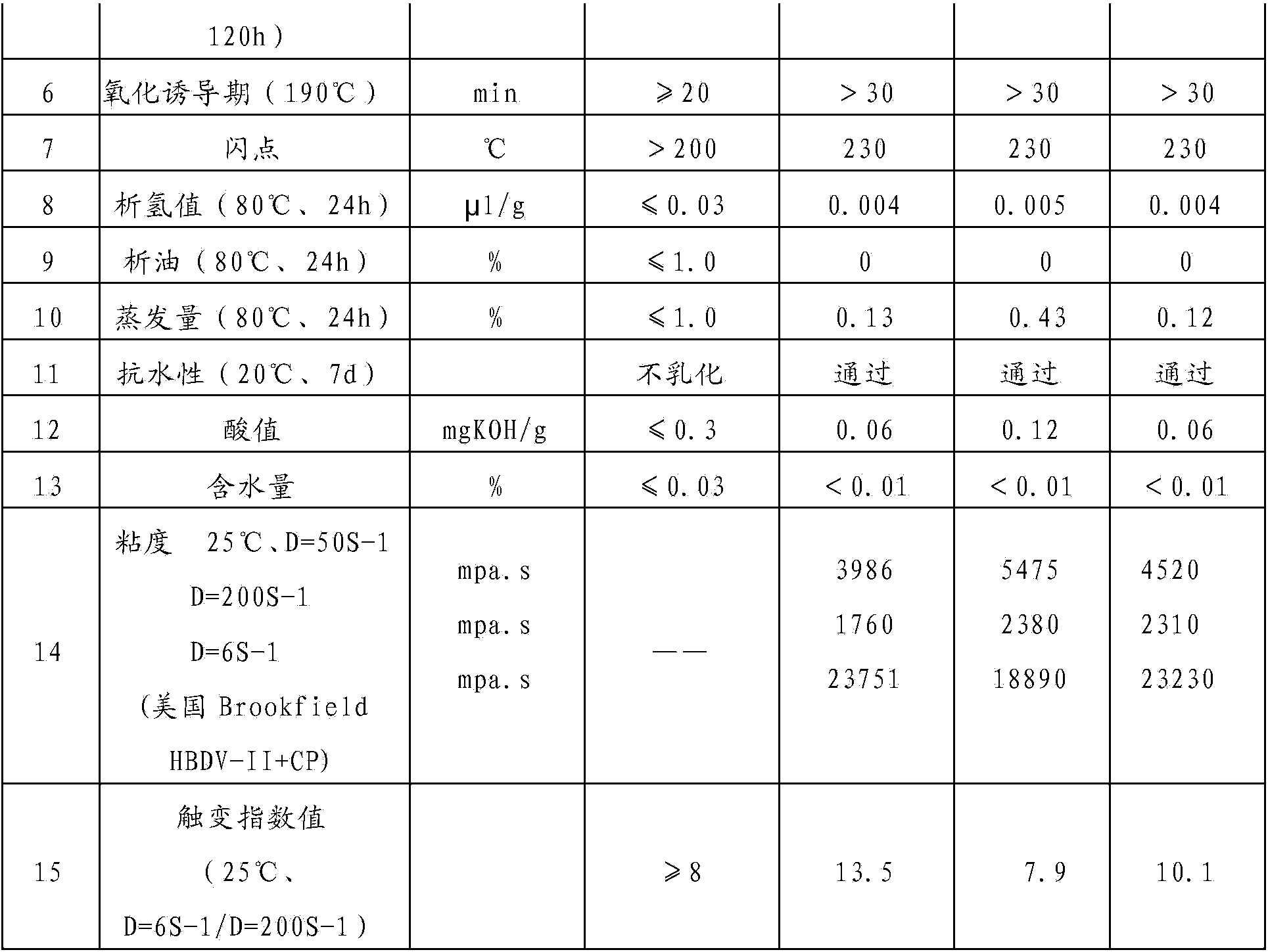

Examples

Embodiment 1

[0035] Add 100 parts by weight of oil separation inhibitor to 800 parts by weight of GTL base oil, heat and stir evenly for 1 to 2 hours, when the temperature rises to 60°C, add 65 parts by weight of thermoplastic synthetic rubber, continue heating and stirring 2 to 5 hours, when the temperature rises to 160°C, stop heating, keep stirring for 1 to 3 hours, add 5 parts by weight of antioxidant and stir for 0.5-1 hour, then cool down to 50°C to 80°C, Add 30 parts by weight of a thickener, fully feed back and stir for 1 to 3 hours, homogeneously grind, vacuum degas, and finally obtain a final product that is a colorless transparent colloid.

[0036] Among the above-mentioned raw materials, the GTL base oil is selected from the GTL base oil produced by Shell, the oil separation inhibitor is selected from Shanghai Top Chemical International Trade Co., Ltd., the model is PB1300 polyisobutylene product, and the thermoplastic synthetic rubber is selected from Kraton Company of the Unit...

Embodiment 2

[0039] Add 90 parts by weight of oil separation inhibitor to 800 parts by weight of GTL base oil, heat and stir evenly for 1 to 2 hours, when the temperature rises to 60°C, add 70 parts by weight of thermoplastic synthetic rubber, continue heating and stirring 2 to 5 hours, when the temperature rises to 160°C, stop heating, keep stirring for 1 to 3 hours, add 5 parts by weight of antioxidant and stir for 0.5-1 hour, then cool down to 50°C to 80°C, Add 35 parts by weight of thickening agent, fully feed back and stir for 1 to 3 hours, homogeneously grind, vacuum degas, and finally obtain the final product as a colorless transparent colloid.

[0040] Among the above-mentioned raw materials, the GTL base oil is selected from the GTL base oil produced by Shell, the oil separation inhibitor is selected from Shanghai Top Chemical International Trade Co., Ltd., the model is PB1300 polyisobutylene product, and the thermoplastic synthetic rubber is selected from Kraton Company of the Uni...

Embodiment 3

[0043] Add 95 parts by weight of oil separation inhibitor to 790 parts by weight of GTL base oil, heat and stir evenly for 1 to 2 hours, when the temperature rises to 60°C, add 70 parts by weight of thermoplastic synthetic rubber, continue heating and stirring 2 to 5 hours, when the temperature rises to 160°C, stop heating, keep stirring for 1 to 3 hours, add 5 parts by weight of antioxidant and stir for 0.5-1 hour, then cool down to 50°C to 80°C, Adding 40 parts by weight of thickener, fully feeding back and stirring for 1 to 3 hours, homogeneous grinding, vacuum degassing, and finally the final product obtained is a colorless transparent colloid.

[0044] Among the above-mentioned raw materials, the GTL base oil is selected from the GTL base oil produced by Shell, the oil separation inhibitor is selected from Shanghai Top Chemical International Trade Co., Ltd., the model is PB2400 polyisobutylene product, and the thermoplastic synthetic rubber is selected from Kraton Company ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com