Heat dissipation device and method of pulse type high-power laser

A high-power laser and heat dissipation device technology, applied in the direction of laser cooling device, laser parts, etc., can solve the problems of large heat dissipation, affecting other instruments, and fast heat dissipation process, so as to avoid burns, prolong working time and reduce temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

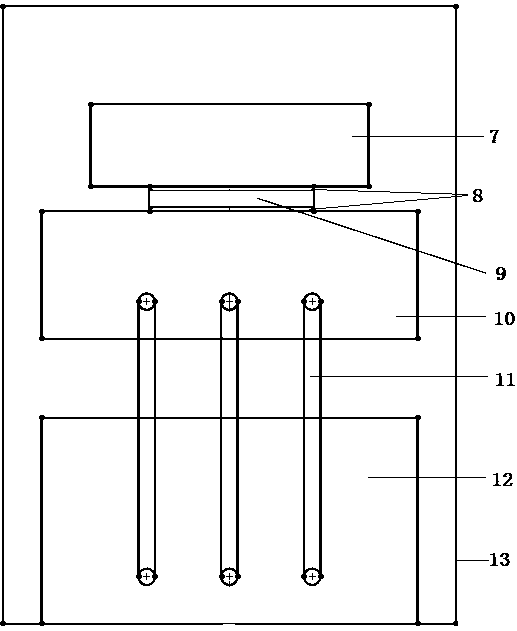

[0034] The cooling device of the pulsed high-power laser of the present invention, such as figure 2 As shown, it includes a heat conduction device bonded to the laser 7, and the heat conduction device includes a semiconductor cooling chip 9 and a heat conducting metal block 10 in this embodiment, and the cold end of the semiconductor cooling chip 9 is directly bonded to the laser 7 One end of the heat-conducting metal block 10 is bonded to the hot end of the semiconductor cooling plate 9, and the other end is connected to the heat-conducting tube 11. In this embodiment, the heat-conducting tube 11 extends into the inside of the heat-conducting metal block 10 , to better transfer heat.

[0035] The present invention is more suitable for pulsed high-power lasers. The heat conduction device is connected with at least one heat conduction tube 11. The number of the heat conduction tubes 11 is set according to the internal space of the device and needs. In this embodiment, the heat...

Embodiment 2

[0041] On the basis of the heat dissipation device of the pulsed high-power laser described in Embodiment 1, the contact surface of the semiconductor cooling plate 9 and the laser 7 is evenly coated with a heat-conducting material 8; the heat-conducting metal block 10 in this embodiment is Red copper, the surface of the heat-conducting metal block 10 is evenly coated with a heat-conducting material 8; the heat-conducting material 8 adopts heat-conducting silicone grease in this embodiment, and the soft heat-conducting silicone grease can ensure that the contact area between each device is the largest. In order to improve thermal conductivity, the thermal conductive material 8 can also use other materials, such as thermal conductive material 8 such as thermal conductive paste, heat dissipation paste, heat dissipation silicone grease, etc.

[0042] The contact part between the heat pipe 11 and the phase change material 12 is sealed, and the heat pipe 11 can adopt a threaded pipe,...

Embodiment 3

[0045] A heat dissipation method adopting the heat dissipation device of the pulsed high-power laser described in the above embodiments comprises the following steps:

[0046] (1) The heat generated by the laser 7 is absorbed by the cold end of the semiconductor cooling plate 9 in the heat conduction device, and transferred to the heat conduction metal block 10, namely red copper, through its hot end, and the heat is absorbed by the red copper and then passed through One or more of the heat pipes 11 are transferred to the phase change wax;

[0047] (2) The phase-change wax absorbs the heat transferred by the heat pipe 11 and stores it, and the heat stored in the phase-change wax slowly dissipates to the outside through the shell 13 in contact with it.

[0048] The heat dissipation method also includes: part of the heat absorbed by the heat-conducting metal block 10 is directly dissipated to the outside through the shell 13 in contact with it; and most of the heat is absorbed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com