Sweet potato rotary tillage ridging transplanting combined operation machine

A combined operation machine and sweet potato technology, which is applied in the direction of transplanting machinery, tillage machinery, agricultural machinery and machinery, etc., can solve the problem of not being able to simultaneously realize rotary tillage and land preparation, soil raising and ridge building, crushing stubble, ditching and seedling release, suppression, Problems such as repairing ridges, pushing ridges, and planting cannot continue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

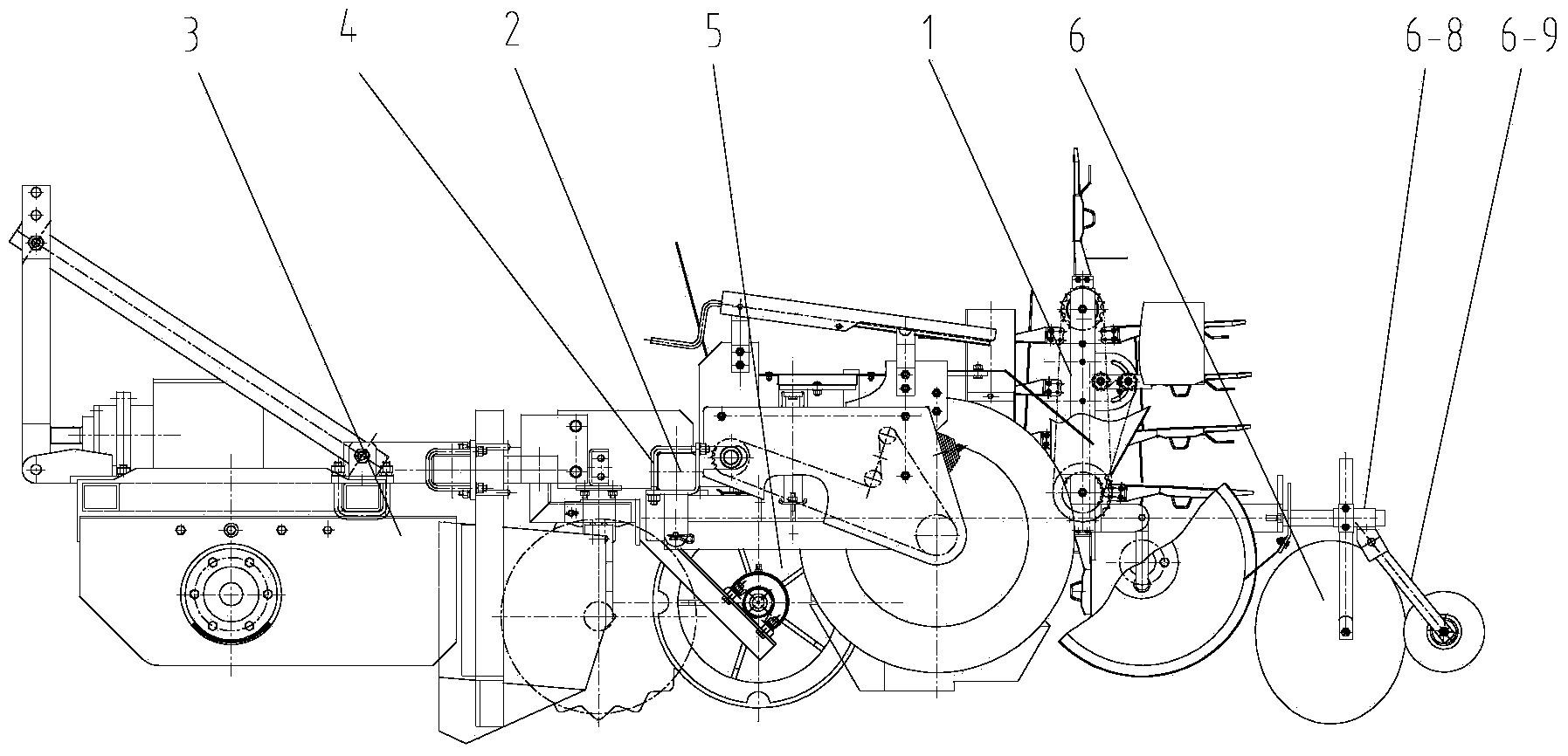

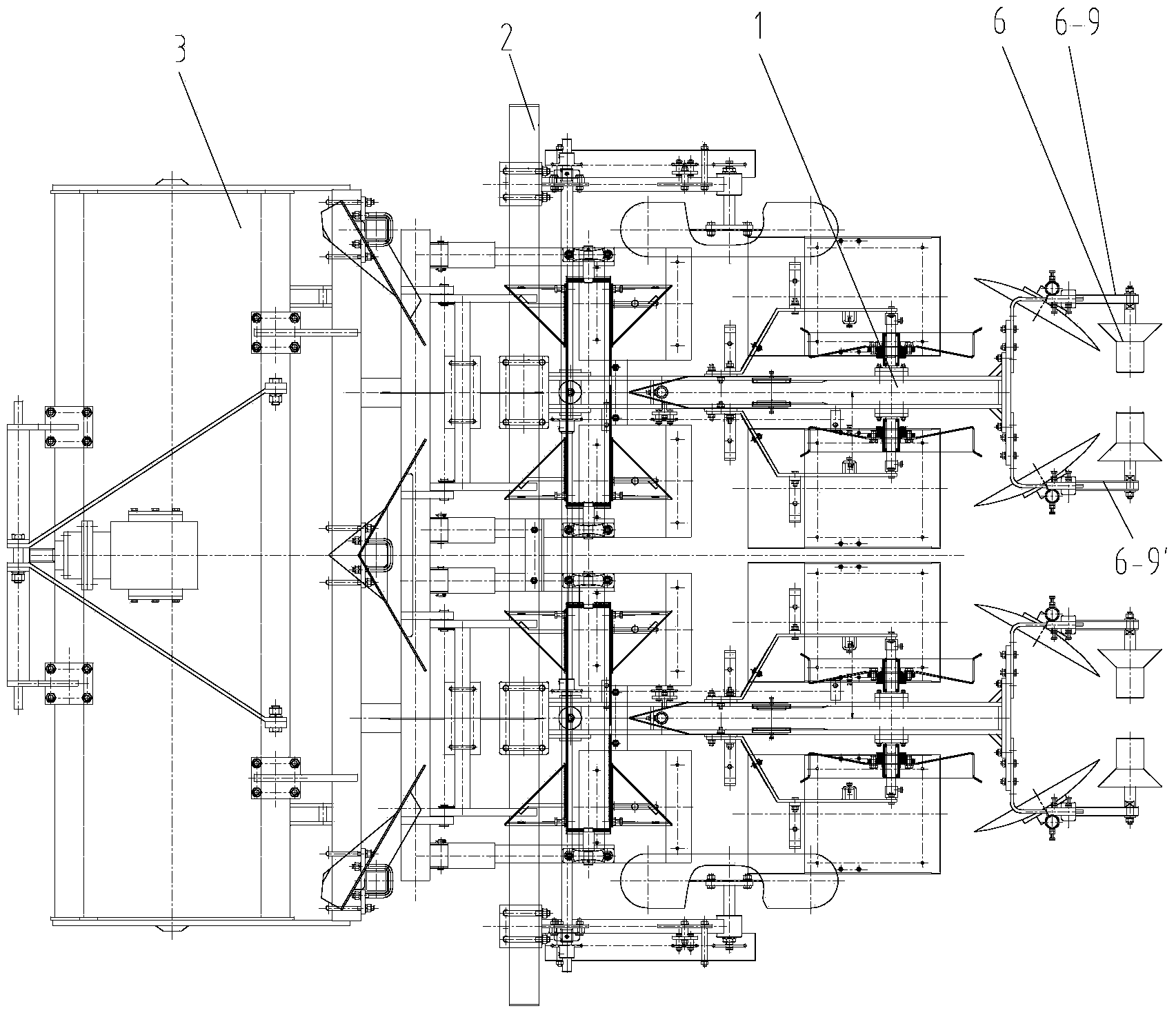

[0025] The overall structure of the sweet potato rotary tillage, ridge and transplant combined operation machine in this embodiment is as follows: figure 1 and figure 2 As shown, a pair of transplanting unit 1 and rotary tillage and ridging unit 3 are connected by connecting frame 2 .

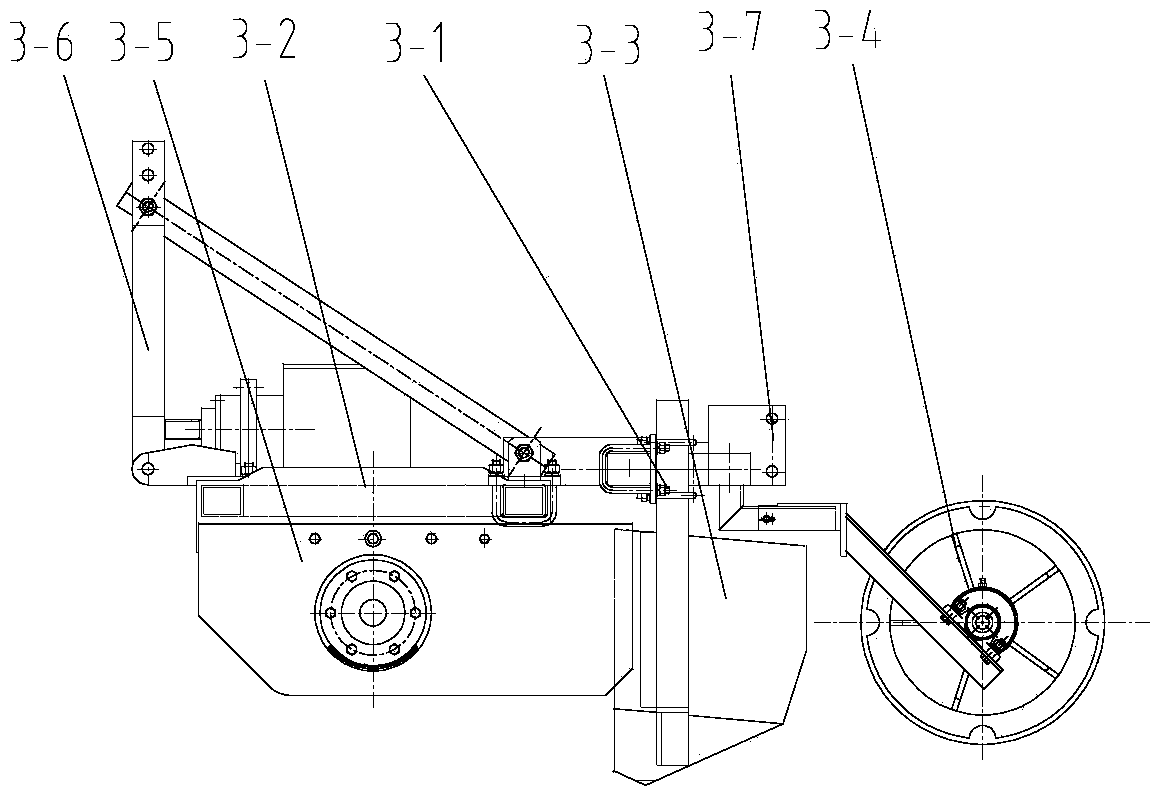

[0026] For the transplanting unit 1, reference may be made to the patent application documents of the background technology, and no detailed description is given. Rotary tillage and ridging unit 3 such as image 3 and Figure 4 As shown, it is mainly composed of a rotary tillage device 3-2 supported on the front, middle and rear sides of the frame 3-1, two pairs of splayed ridge plows 3-3, and two pairs of pressing wheels 3-4. When working, the three-point suspension device at the front end can realize the power connection with the tractor. The rotary tillage device plows and loosens the soil and breaks it. Therefore, two ridges can be played at the same time. The two sides of the rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com