Preparation method of injectable porous calcium phosphate bone repair material

A calcium phosphate bone and repair material technology, applied in the field of medical materials, can solve the problems of not meeting the requirements of bone tissue engineering scaffold materials, long setting time of calcium phosphate bone cement, poor mechanical properties, etc., to improve application comfort and setting time Short, high compressive strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

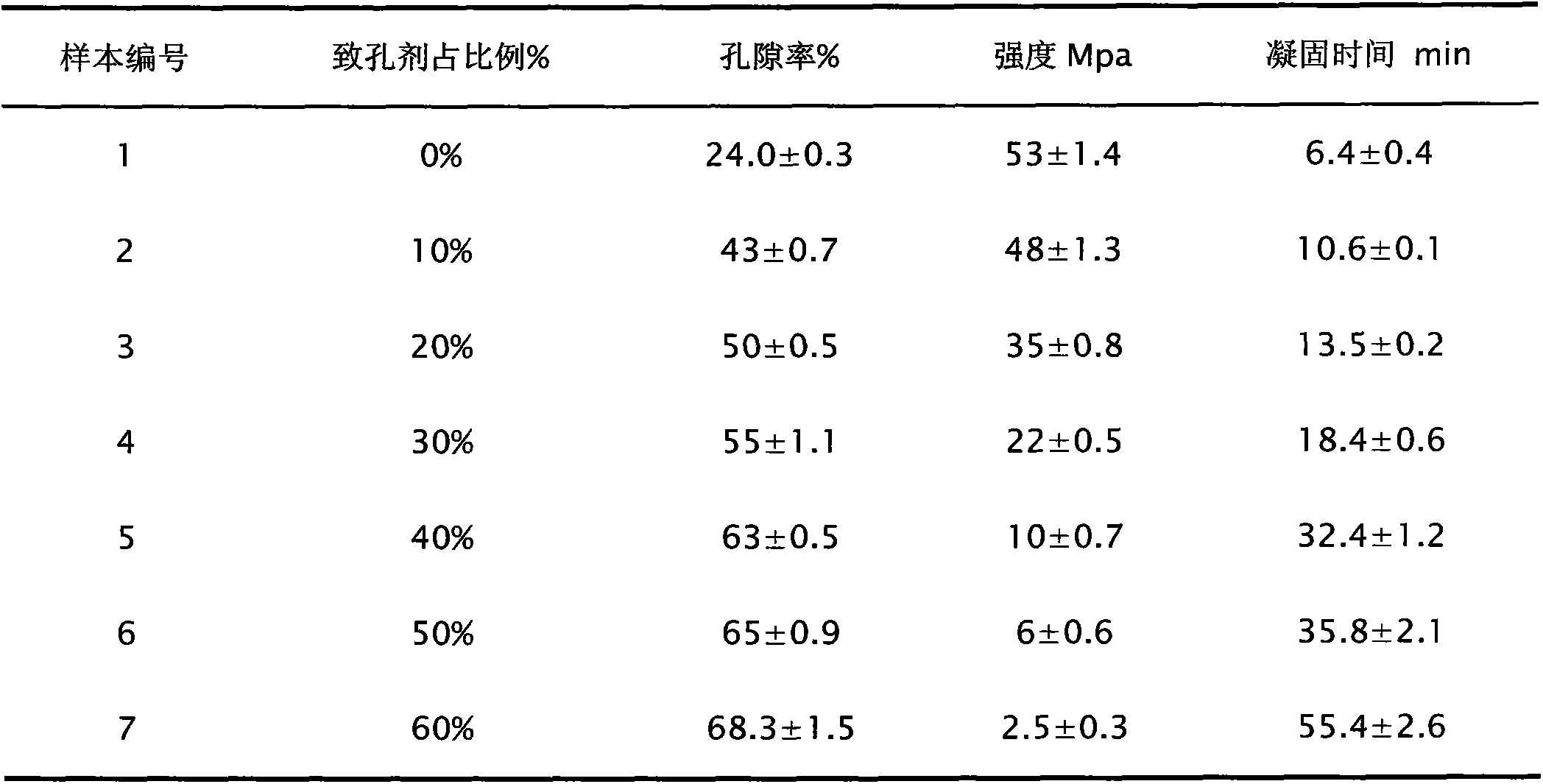

Embodiment 1

[0035] (1) Treat calcium hydrogen phosphate dihydrate at 120°C for 12 hours, sieve after cooling, and then put it into a ball mill, add agate balls and absolute ethanol, ball mill on the ball mill for 12 hours, and dry it in a drying oven at 80°C drying in medium to obtain anhydrous calcium hydrogen phosphate;

[0036] (2) dissolving chitosan, citric acid, and glucose in deionized water in proportions of 3%, 5%, and 15% by mass, stirring and dissolving, forming a solution, standing for 24 hours, and setting aside;

[0037] (3) Put mannitol in the ethanol solution, heat and stir to make it fully dissolved, the volume ratio of mannitol to ethanol is 2:1, then let stand and cool to obtain recrystallized mannitol crystals, and recrystallize The final mannitol crystals were vacuum filtered, dried, passed through a 50-mesh sieve and a 150-mesh sieve respectively, and set aside;

[0038] (4) The liquid phase adopts the solution configured in step (2), and the solid phase is composed...

Embodiment 2

[0041] (1) Dibasic calcium phosphate dihydrate was treated at 120°C for 12 hours, cooled and sieved, then put into a ball mill, added agate balls and absolute ethanol, ball milled on the ball mill for 12 hours, and dried in a drying oven at 80°C drying in medium to obtain anhydrous calcium hydrogen phosphate;

[0042] (2) dissolving chitosan, citric acid, and glucose in deionized water in proportions of 5%, 8%, and 20% by mass, stirring and dissolving, forming a solution, standing for 24 hours, and setting aside;

[0043] (3) Put mannitol in the ethanol solution, heat and stir to make it fully dissolved, the volume ratio of mannitol to ethanol is 1:1, then let stand and cool to obtain recrystallized mannitol crystals, and recrystallize The final mannitol crystals were vacuum filtered, dried, passed through a 50-mesh sieve and a 150-mesh sieve respectively, and set aside;

[0044] (4) The liquid phase adopts the solution configured by step (2), and the solid phase is composed ...

Embodiment 3

[0047] (1) Treat calcium hydrogen phosphate dihydrate at 120°C for 12 hours, sieve after cooling, and then put it into a ball mill, add agate balls and absolute ethanol, ball mill on the ball mill for 12 hours, and dry it in a drying oven at 80°C drying in medium to obtain anhydrous calcium hydrogen phosphate;

[0048] (2) dissolving chitosan, citric acid, and glucose in deionized water in proportions of 1%, 8%, and 10% by mass percentage, stirring and dissolving, forming a solution, standing for 24 hours, and setting aside;

[0049] (3) Put mannitol in the ethanol solution, heat and stir to make it fully dissolved, the volume ratio of mannitol to ethanol is 3:1, then let stand and cool to obtain recrystallized mannitol crystals, and recrystallize The final mannitol crystals were vacuum filtered, dried, passed through a 50-mesh sieve and a 150-mesh sieve respectively, and set aside;

[0050](4) The liquid phase adopts the solution configured in step (2), and the solid phase i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap