PFOA (perfluorooctanoic acid)-containing waste water treatment system

A wastewater treatment system and ammonium perfluorooctanoate technology, which are applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. The effect of avoiding contamination and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

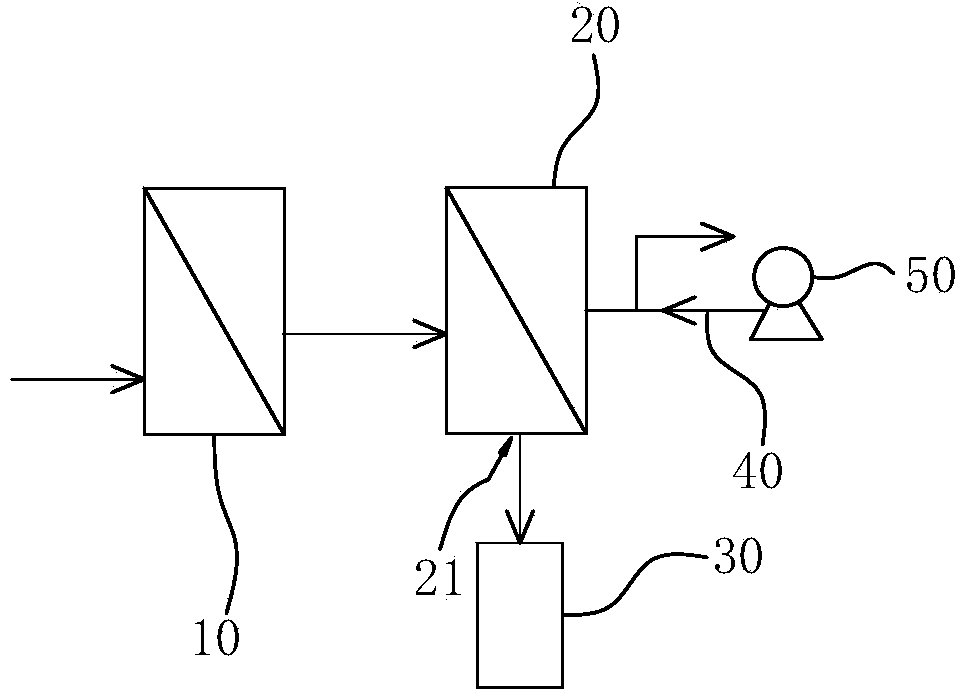

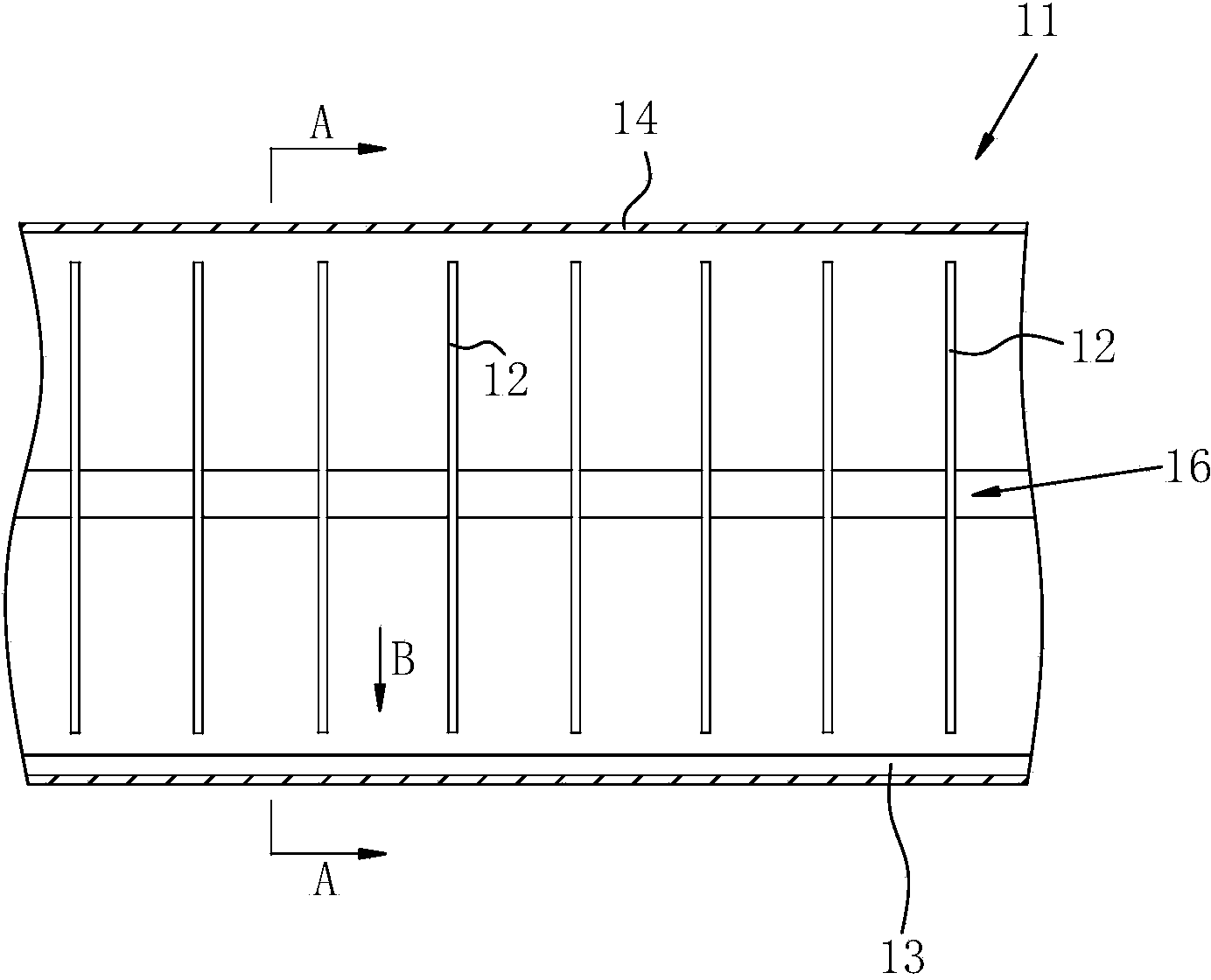

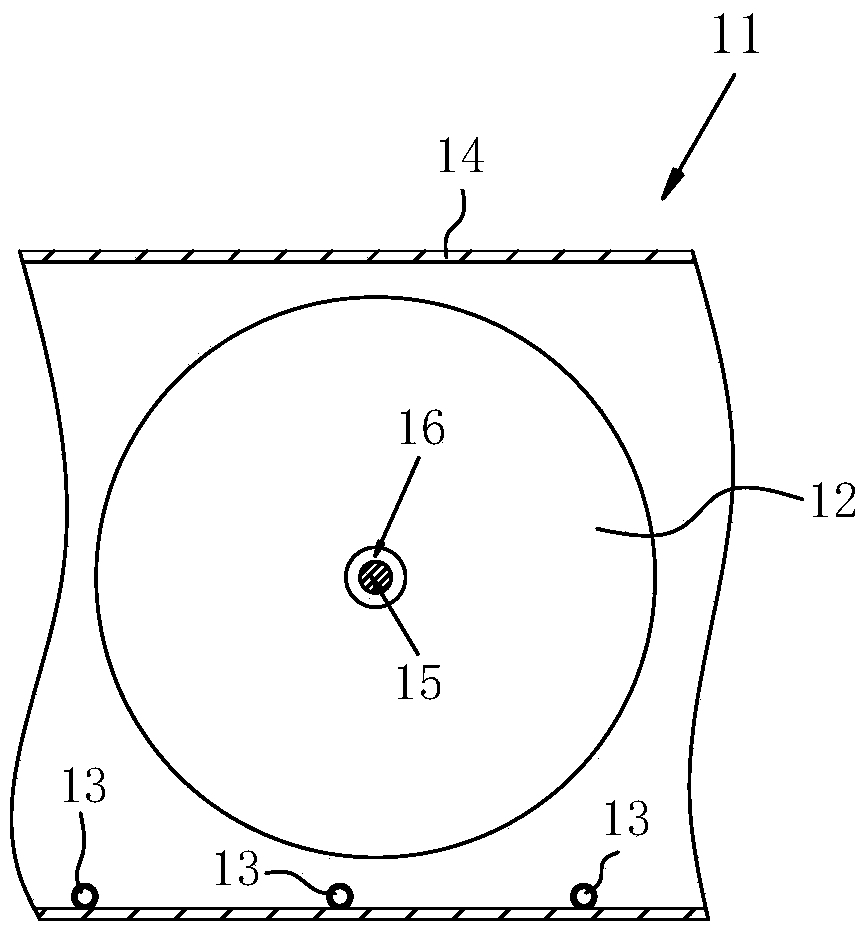

[0011] A wastewater treatment system containing ammonium perfluorooctanoate, such as Figure 1-4 As shown, it includes an ultrafiltration unit 10 and a nanofiltration unit 20 arranged in sequence, the input end of the nanofiltration unit 20 is connected to the permeate outlet of the ultrafiltration unit 10, and the concentrated solution outlet 21 of the nanofiltration unit 20 is connected to the perfluorooctanoic acid ammonium concentrate The collection device 30 is connected, the membrane element of the ultrafiltration unit 10 is a plate membrane 11, the membrane plates 12 of the plate membrane 11 are arranged at intervals in the housing 14, the inner bottom surface of the housing 14, along the bottom of the housing 14 At least one pipe body 13 is provided along the length direction. One end of the pipe body 13 is closed, and the other end of the pipe body 13 is connected to the air source. Air holes 131 in the pipe wall. By arranging the pipe body 13 in the housing of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com