Method for increasing yield of titanium-type agglomerate schreyerite

A vanadium-titanium sinter and high-titanium type technology, which is applied in the field of sinter preparation, can solve the problems of high return rate, insufficient low-temperature liquid phase, and large sintering cycle, and achieve the effect of increasing production and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0051] Production of acidic oxidation roasting pellets: mix Baima vanadium-titanium magnetite concentrate with a proportion of 98% and bentonite with a proportion of 2.0%, and add water to make a mixture, and control the moisture content in the mixture to 7%. Then pelletize the mixture for 5 minutes in a disc pelletizer with a diameter of 1000 mm and a rotating speed of 3 r / min to obtain pellets with a particle size of 10-16 mm. Put the pellets into the roasting furnace after standing in the air for 24 hours, raise the temperature from 20°C to 520°C at a rate of 10°C / min, take them out after roasting for 50min, and let them cool naturally for use.

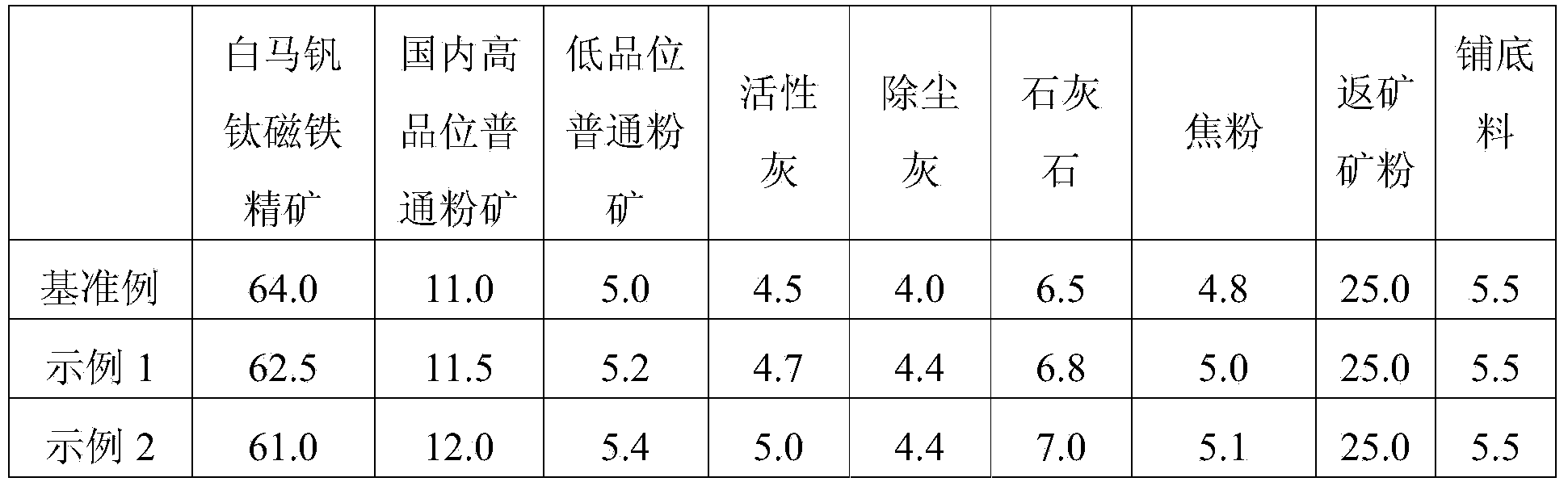

[0052] The proportion of Baima vanadium-titanium magnetite concentrate is 62.5%, the proportion of domestic high-grade ordinary fine ore is 11.5%, the proportion of domestic low-grade ordinary fine ore is 5%, the proportion of active ash is 4.7%, and the proportion of limestone is 6.8%. , The ratio of coke powder is 5.0%, the ratio...

example 2

[0055] Production of acidic oxidation roasting pellets: mix Baima vanadium-titanium magnetite concentrate with a proportion of 98% and bentonite with a proportion of 2.0%, and add water to make a mixture, and control the moisture content in the mixture to 9%. Then pelletize the mixture for 5 minutes in a disc pelletizer with a diameter of 1000 mm and a rotating speed of 3 r / min to obtain pellets with a particle size of 10-16 mm. Put the pellets into the roasting furnace after standing in the air for 24 hours, raise the temperature from 20°C to 520°C at a rate of 10°C / min, take them out after roasting for 50min, and let them cool naturally for use.

[0056] The proportion of Baima vanadium-titanium magnetite concentrate is 61%, the proportion of domestic high-grade ordinary fine ore is 12%, the proportion of domestic low-grade ordinary fine ore is 5.4%, the proportion of active ash is 5.0%, and the proportion of limestone is 7.0%. , The ratio of coke powder is 5.2%, the ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com