Non-impact net shaking device

A screen shaker and reducer technology, which is applied in textiles and papermaking, papermaking, paper machine wet end, etc., can solve the problems affecting the stable operation of the paper machine and the stability of product quality, the effect of the high-speed paper machine is not obvious, and the failure rate of equipment operation The problem of rising and other problems can be achieved, and the effect of stable amplitude, good guiding precision and low equipment failure rate can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

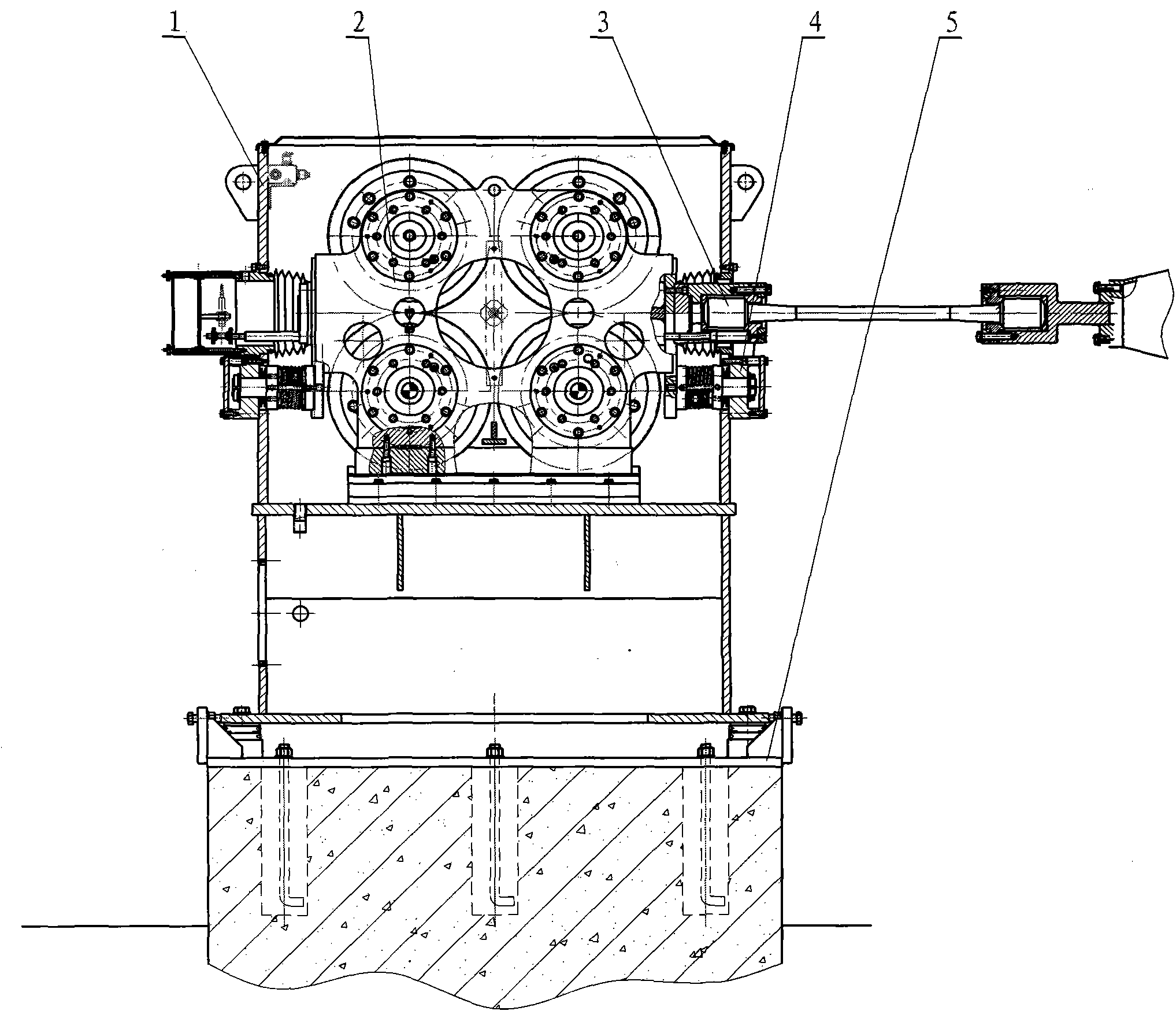

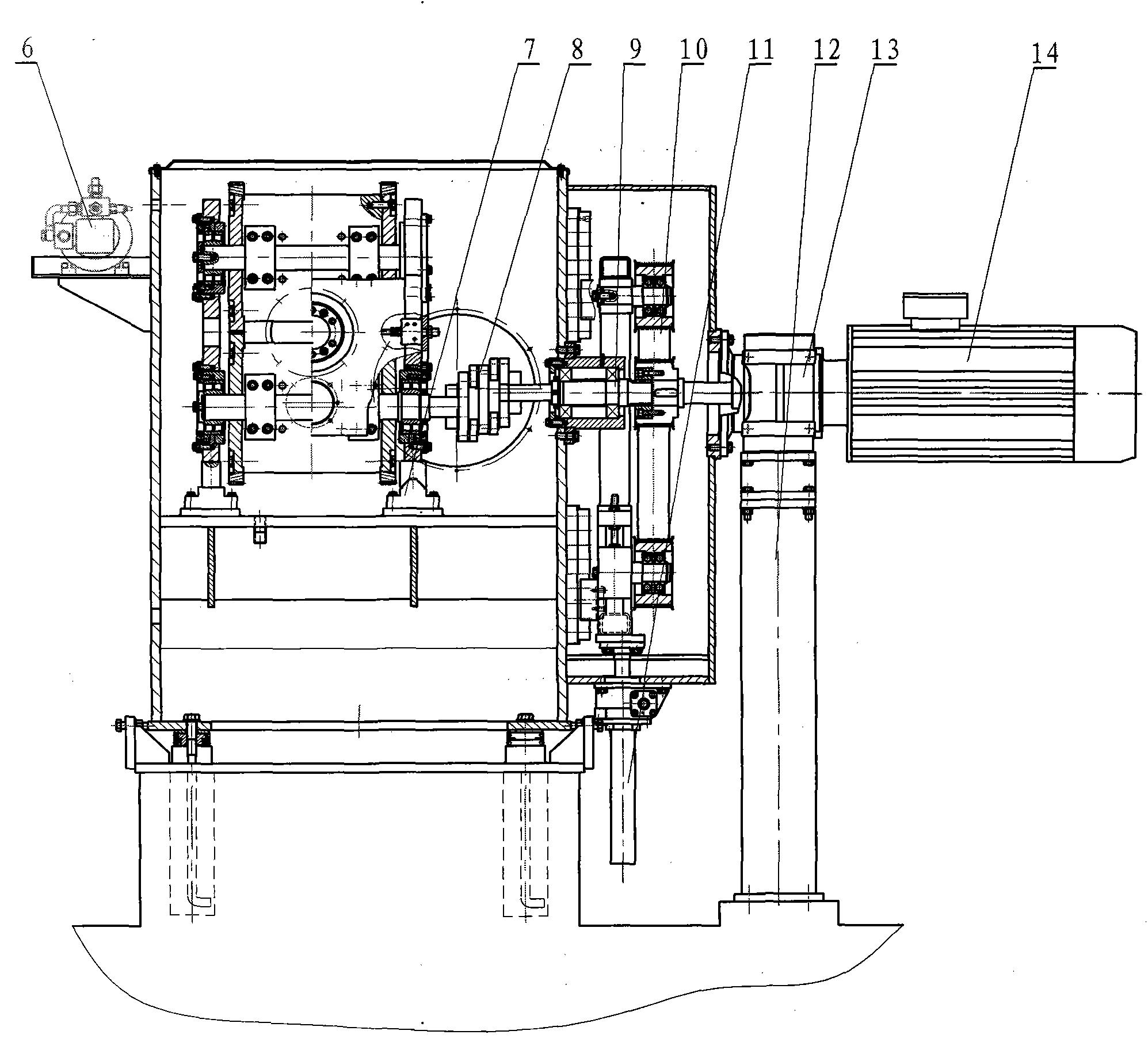

[0019] A non-impact shaker, such as figure 1 , 2 As shown, it includes: a box 1, the box 1 is installed on the base plate 5, the base plate 5 is fixed on the concrete base, and the transmission mechanism and the amplitude adjustment mechanism are installed on the box 1 10. The connection mechanism 3, the lubrication system 6 and the sliding guide rail device 7, the bias balance wheel 2 is installed on the sliding guide rail device 7, and the transmission mechanism includes a reducer 13, a main transmission shaft 9, and a parallel shaft coupling 8 , the main drive shaft of the eccentric balance wheel and the slave drive shaft of the eccentric balance wheel, the reducer 13 is installed on the reducer bracket 12, the reducer bracket 12 is fixed on the concrete base, and the reducer 13 is connected to The main transmission shaft 9, the main transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com