Heat preservation and intelligent anticorrosion oil pipe for high sulfur natural gas well

A natural gas, high-sulfur technology, applied in the direction of drill pipe, casing, drilling equipment, etc., to achieve excellent thermal stability and corrosion resistance, prevent corrosion of tubing, and solve the effect of easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

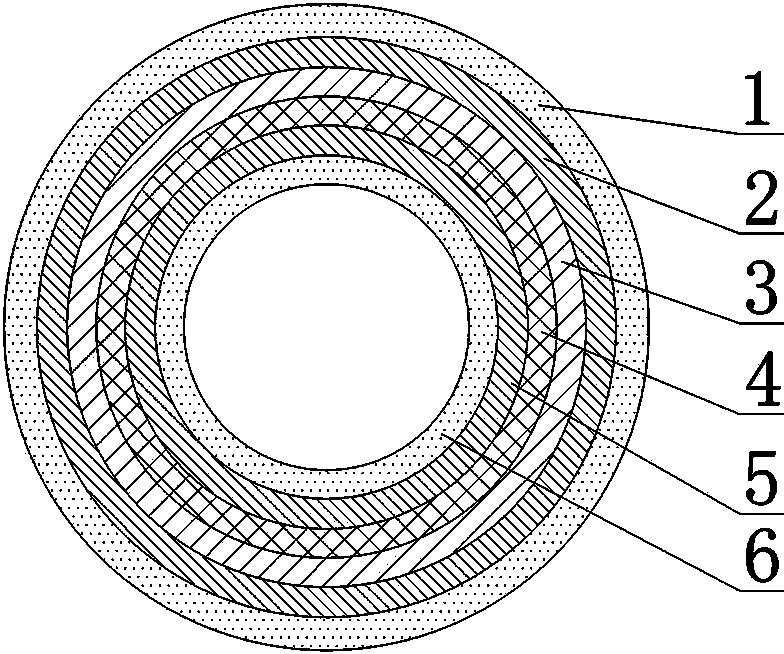

[0025] like figure 1 As shown, a thermal insulation intelligent anti-corrosion tubing for high-sulfur natural gas wells is composed of six layers, and along the direction from the inside to the outside are the internal anti-corrosion and drag-reducing layer 6, the internal intelligent anti-corrosion layer 5, the thermal insulation layer 4, The supporting layer 3, the outer smart anti-corrosion layer 2 and the outer anti-corrosion and drag-reducing layer 1, that is, the inner smart anti-corrosion layer 5 covers the outside of the inner anti-corrosion and drag-reducing layer 6, and the insulation layer 4 covers the outside of the inner smart anti-corrosion layer 5, supporting Layer 3 is coated on the outside of the thermal insulation layer 4, the outer intelligent anti-corrosion layer 2 is coated on the outside of the support layer 3, and the outer anti-corrosion and drag-reducing layer 1 is coated on the outside of the outer intelligent anti-corrosion layer 2;

[0026] The raw ...

Embodiment 2

[0031] like figure 1 As shown, a thermal insulation intelligent anti-corrosion tubing for high-sulfur natural gas wells is composed of six layers, and along the direction from the inside to the outside are the internal anti-corrosion and drag-reducing layer 6, the internal intelligent anti-corrosion layer 5, the thermal insulation layer 4, The supporting layer 3, the outer smart anti-corrosion layer 2 and the outer anti-corrosion and drag-reducing layer 1, that is, the inner smart anti-corrosion layer 5 covers the outside of the inner anti-corrosion and drag-reducing layer 6, and the insulation layer 4 covers the outside of the inner smart anti-corrosion layer 5, supporting Layer 3 is coated on the outside of the thermal insulation layer 4, the outer intelligent anti-corrosion layer 2 is coated on the outside of the support layer 3, and the outer anti-corrosion and drag-reducing layer 1 is coated on the outside of the outer intelligent anti-corrosion layer 2;

[0032] The raw ...

Embodiment 3

[0037] like figure 1 As shown, a thermal insulation intelligent anti-corrosion tubing for high-sulfur natural gas wells is composed of six layers, and along the direction from the inside to the outside are the internal anti-corrosion and drag-reducing layer 6, the internal intelligent anti-corrosion layer 5, the thermal insulation layer 4, The supporting layer 3, the outer smart anti-corrosion layer 2 and the outer anti-corrosion and drag-reducing layer 1, that is, the inner smart anti-corrosion layer 5 covers the outside of the inner anti-corrosion and drag-reducing layer 6, and the insulation layer 4 covers the outside of the inner smart anti-corrosion layer 5, supporting Layer 3 is coated on the outside of the thermal insulation layer 4, the outer intelligent anti-corrosion layer 2 is coated on the outside of the support layer 3, and the outer anti-corrosion and drag-reducing layer 1 is coated on the outside of the outer intelligent anti-corrosion layer 2;

[0038] The raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com