Internal entering slot-type mortar pump

A technology of mortar pump and tank type, which is applied in the field of mortar pump equipment, can solve the problems of inability to use slurry tanks in combination, unreasonable structural design, and large space occupation, and achieve the effects of simple structure, flexible layout, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

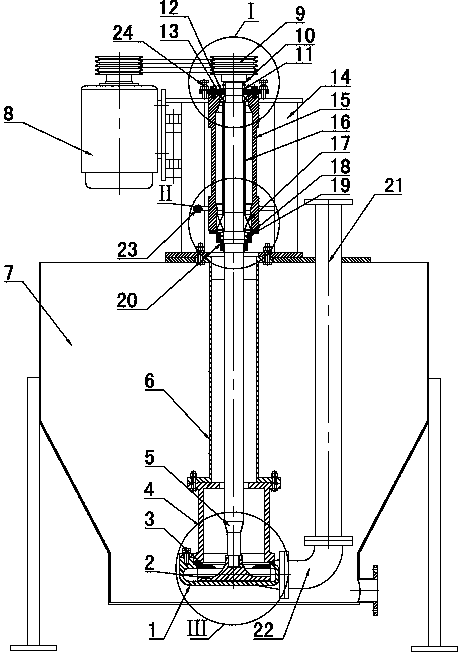

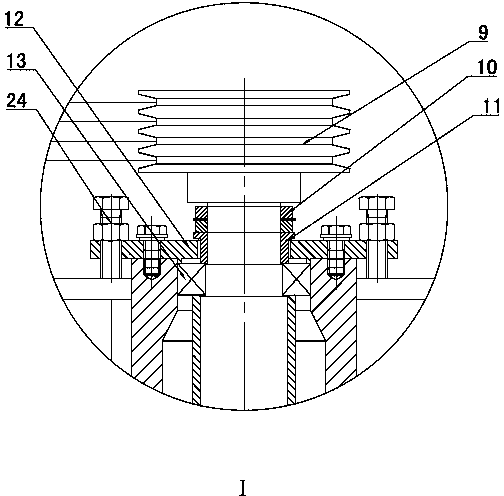

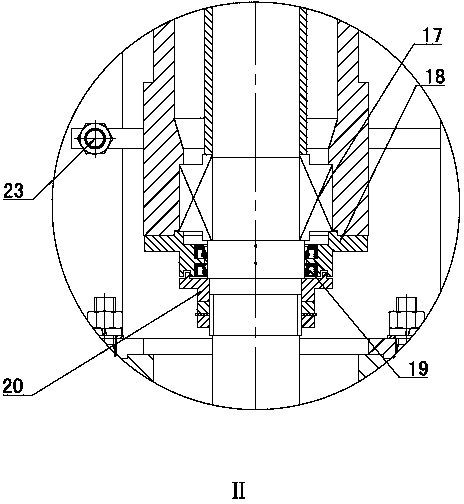

[0028] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0029] Refer to attached figure 1 , 4 : An internal grooved mortar pump, including a pump casing 1, an impeller 2, a pump shaft 5, a slurry tank 7, a motor 8, a bearing support assembly and a discharge pipeline. The slurry tank 7 is supported on the ground by surrounding brackets, and the pump housing 1 is installed at the inner bottom of the slurry tank 7 through a bearing support assembly. The pump casing 1 is provided with an impeller 2 with the impeller fins facing upwards, the bottom of the pump casing 1 is sealed, and a discharge port is opened on the side. The upper part of the pump casing 1 is open and connected to the connecting pipe 6 through the connecting frame 4. The upper opening of the pump casing 1 is provided with a back cover 3. The upper part of the connecting pipe 6 is connected to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com