An energy-saving organic heat carrier dynamic heat energy intelligent distribution system

A technology of intelligent distribution and carrier, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of not ensuring process heat demand, endangering the safety of boilers and pipelines, and axial vibration of pipeline resonance. , to reduce the failure rate of the boiler, protect the boiler, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

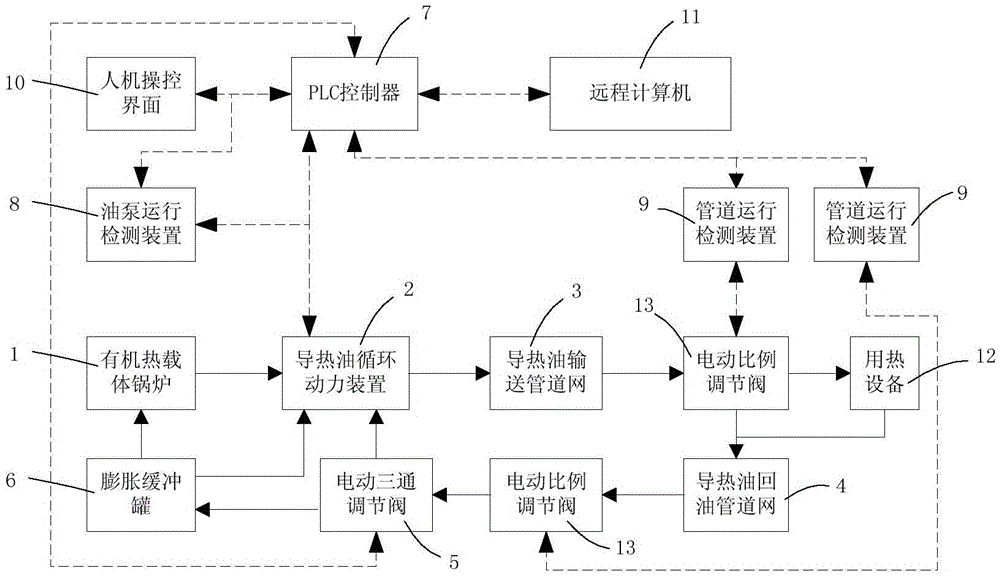

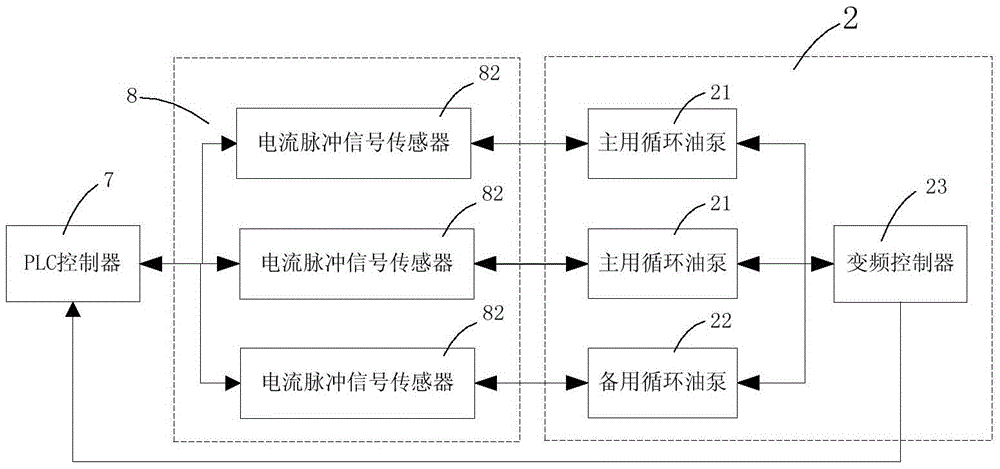

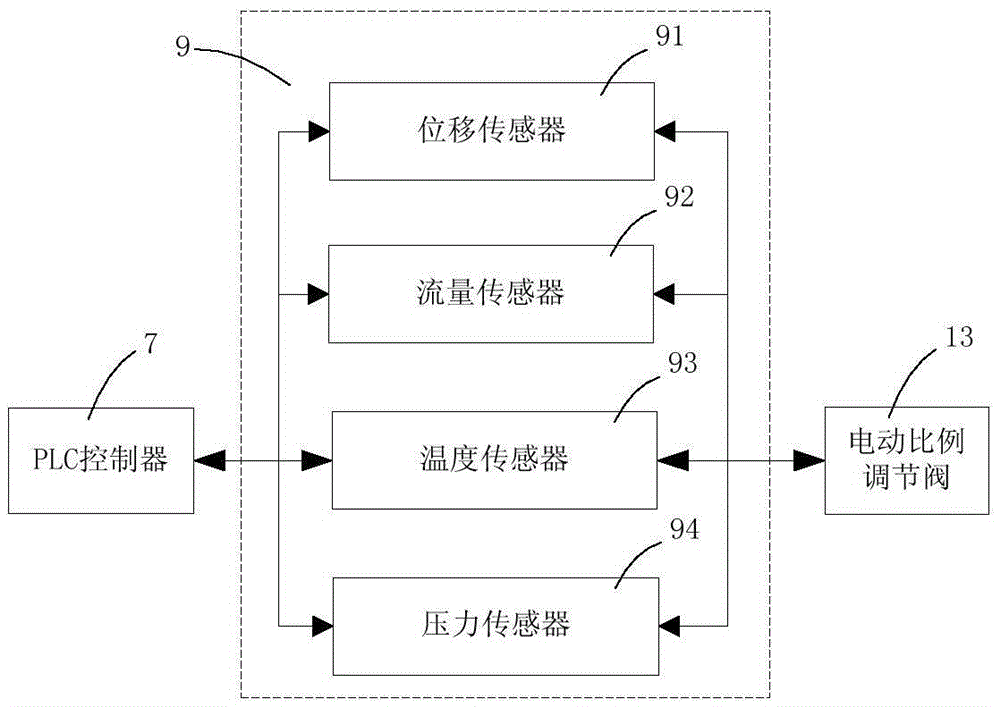

[0033] refer to figure 1, an energy-saving organic heat carrier dynamic heat energy intelligent distribution system of the present invention, comprising an organic heat carrier boiler 1, a heat transfer oil circulation power device 2, a heat transfer oil delivery pipeline network 3, a heat transfer oil return pipeline network 4, and an electric three-way regulating valve 5. Expansion buffer tank 6, PLC controller 7, oil pump operation detection device 8, multiple pipeline operation detection devices 9, multiple electric proportional regulating valves 13, man-machine control interface 10, remote computer 11, the organic heat carrier boiler The output of 1 is connected to the heat transfer oil circulation power unit 2, and the heat transfer oil circulation power unit 2 transports the heat transfer oil to the input end of the heat-using equipment 12 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com