Unsmooth static compensation method for ultralow-frequency horizontal vibration table guide rail

A static compensation and ultra-low frequency technology, applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve the problems of increasing the stroke of the vibration table, high cost of implementation, and difficult to meet, and achieve the goal of reducing the accuracy of the guide rail Requirement, improvement of compensation effect, effect of obvious compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

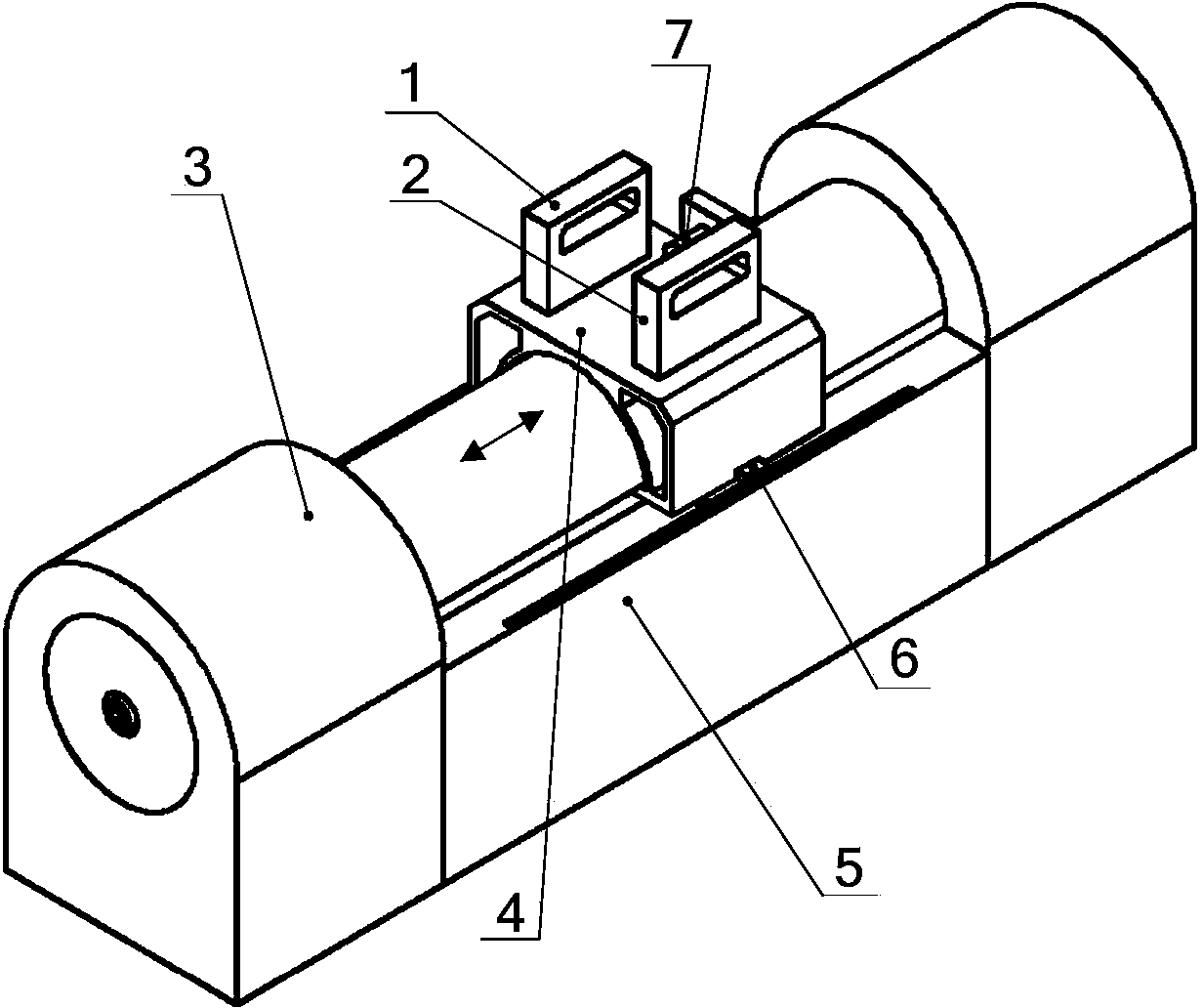

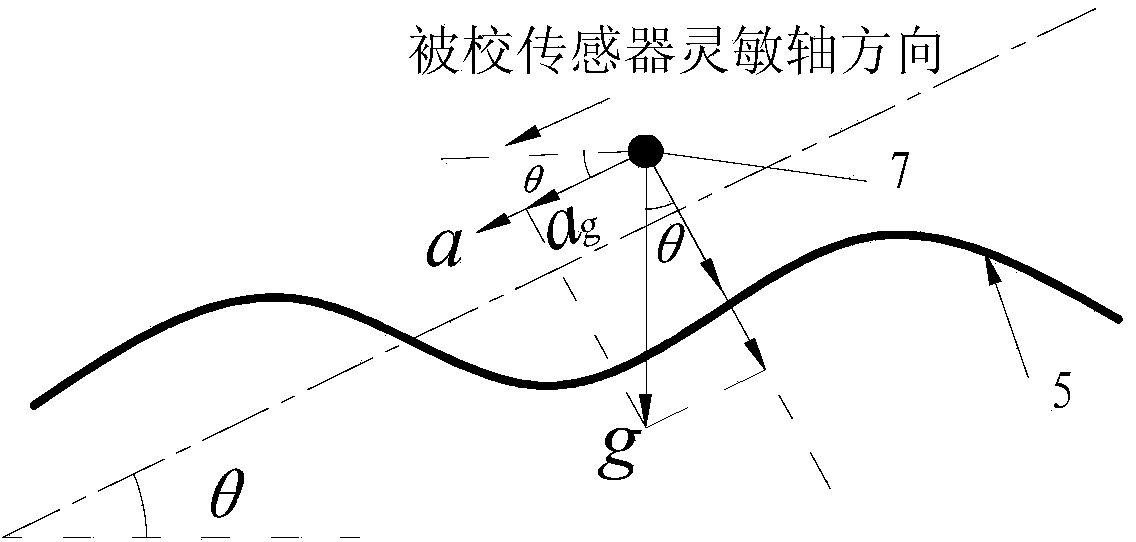

[0035] In this embodiment, two levels are used to measure the pitch angle of the moving part (sliding table) of the vibrating table, and a linear grating ruler is used to measure the real-time displacement of the sliding table as an example. figure 1 and 2 shown.

[0036] The static compensation method for the irregularity of the guide rail of the ultra-low frequency horizontal vibrating table includes the following steps:

[0037] (1) The static performance of the uneven guide rail of the ultra-low frequency horizontal vibration table is measured:

[0038] (1.1) Place the two spirit levels 1 and 2 symmetrically on the slide 4 of the ultra-low frequency vibration table 3, push the slide 4 to move along the guide rail 5, and measure and record the two statically at certain distances within the entire range of motion of the slide 4. The average pitch angle of slide 4 output by levels 1 and 2 θ (Refer to the horizontal direction, the same below);

[0039] (1.2), while perfor...

Embodiment 2

[0055] Embodiment 1 uses a level to detect the pitch angle of the moving part of the vibrating table (sliding table), calculates the resulting gravitational acceleration component, and then calculates the pitch of the sliding table based on the assumption that the influence of the unevenness of the guide rail on the high-frequency vibration calibration can be ignored. to the output signal of the sensor to be calibrated, and this embodiment takes the output signal of the sensor to be calibrated by directly detecting the pitch of the sliding platform by using the sensor to be calibrated with zero frequency response, and using a linear grating ruler to measure the real-time displacement of the sliding platform as an example illustrate.

[0056] The static compensation method for the irregularity of the guide rail of the ultra-low frequency horizontal vibrating table includes the following steps:

[0057] (1) Install the sensor to be calibrated on the sliding table of the ultra-lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com