Semiconductor light-emitting chip, semiconductor lighting fixture and manufacturing method thereof

A technology of light-emitting chips and semiconductors, which is applied in the direction of semiconductor devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of high comprehensive manufacturing costs of lamps, increased process links and production equipment, and accelerated light decay of light-emitting chips. Achieve no heat conduction bottleneck, save the use of raw materials, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

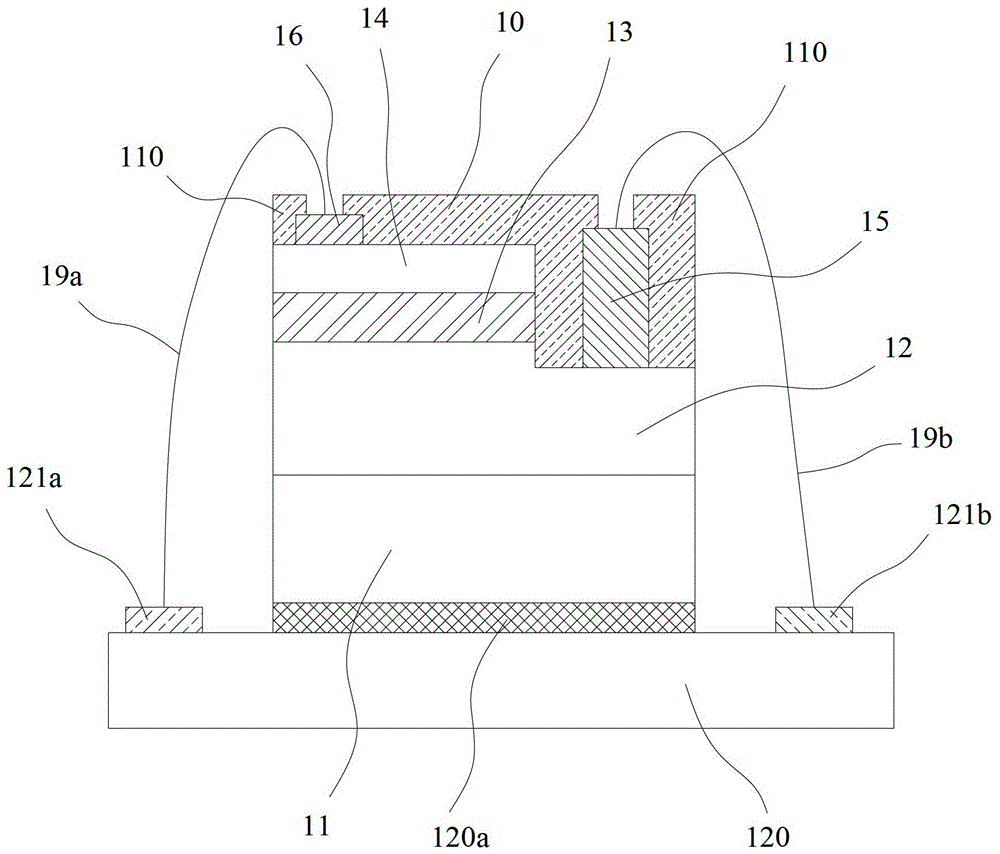

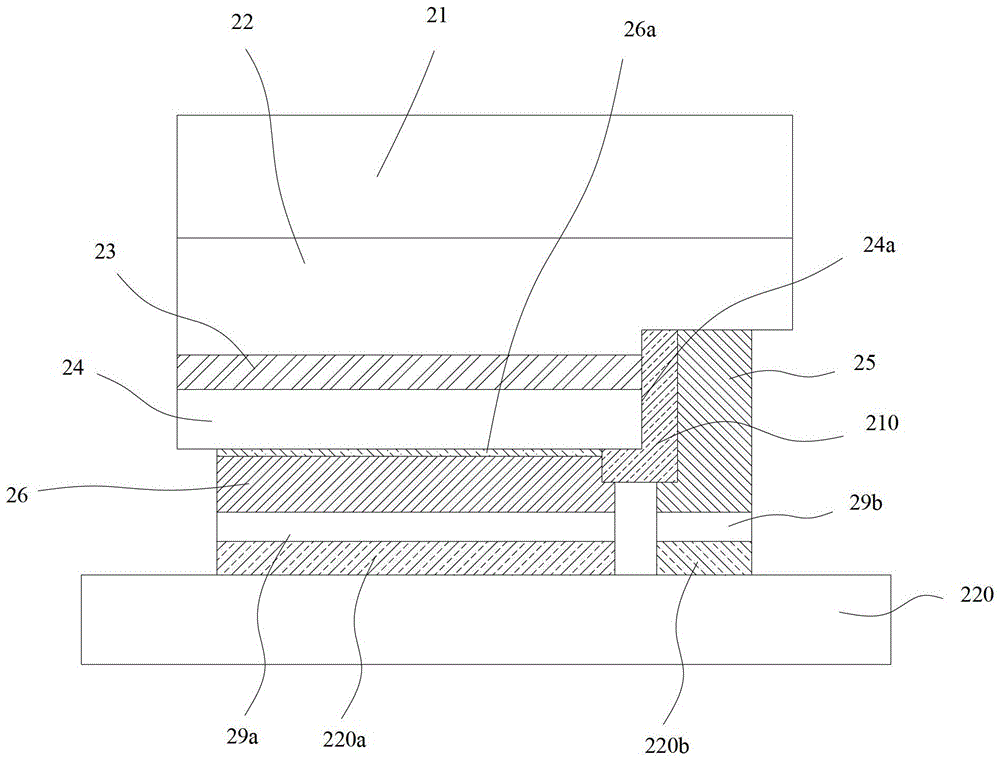

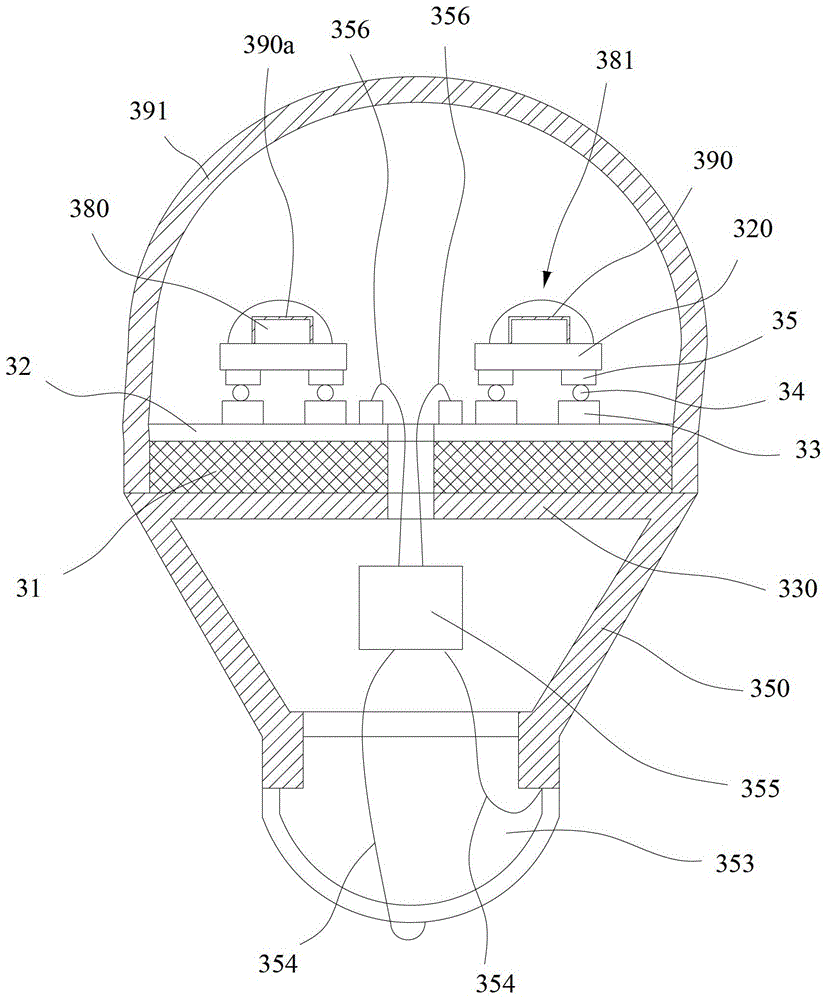

[0055] Such as Figure 4 Shown is an embodiment of a semiconductor light-emitting chip suitable for reflow soldering in the present invention, including a sapphire substrate 41, an n-type conductive layer 42, a light-emitting layer 43, a p-type conductive layer 44, an n-type electrode 45, a p-type Electrodes 46, n-type pads 45a, p-type pads 46a, metal-based thermal pads 47a, insulating layers 410, 410a, current spreading layers 44b, n-type electrode steps 44a, sapphire substrate steps 44c, LED brackets 420, n Type pad 420a, p-type pad 420b, thermal pad 420c, metal solder 421a, 421b, 421c, etc. Among them, the n-type conductive layer, the light-emitting layer and the p-type conductive layer together form a semiconductor stack; the sapphire substrate 41, the n-type conductive layer 42, the light-emitting layer 43, the p-type conductive layer 44, the n-type electrode 45, the p-type electrode 46. N-type welding pad 45a, p-type welding pad 46a, metal-based heat-conducting pad 47...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com