Single-mode photonic crystal edge-emitting semiconductor laser device

A technology of photonic crystals and semiconductors, which is applied to the structure of semiconductor lasers, lasers, and optical waveguide semiconductors. It can solve problems such as large changes, intensified side-mode competition, and increased far-field angles, and achieves low cost, compact structure, and ease of use. integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

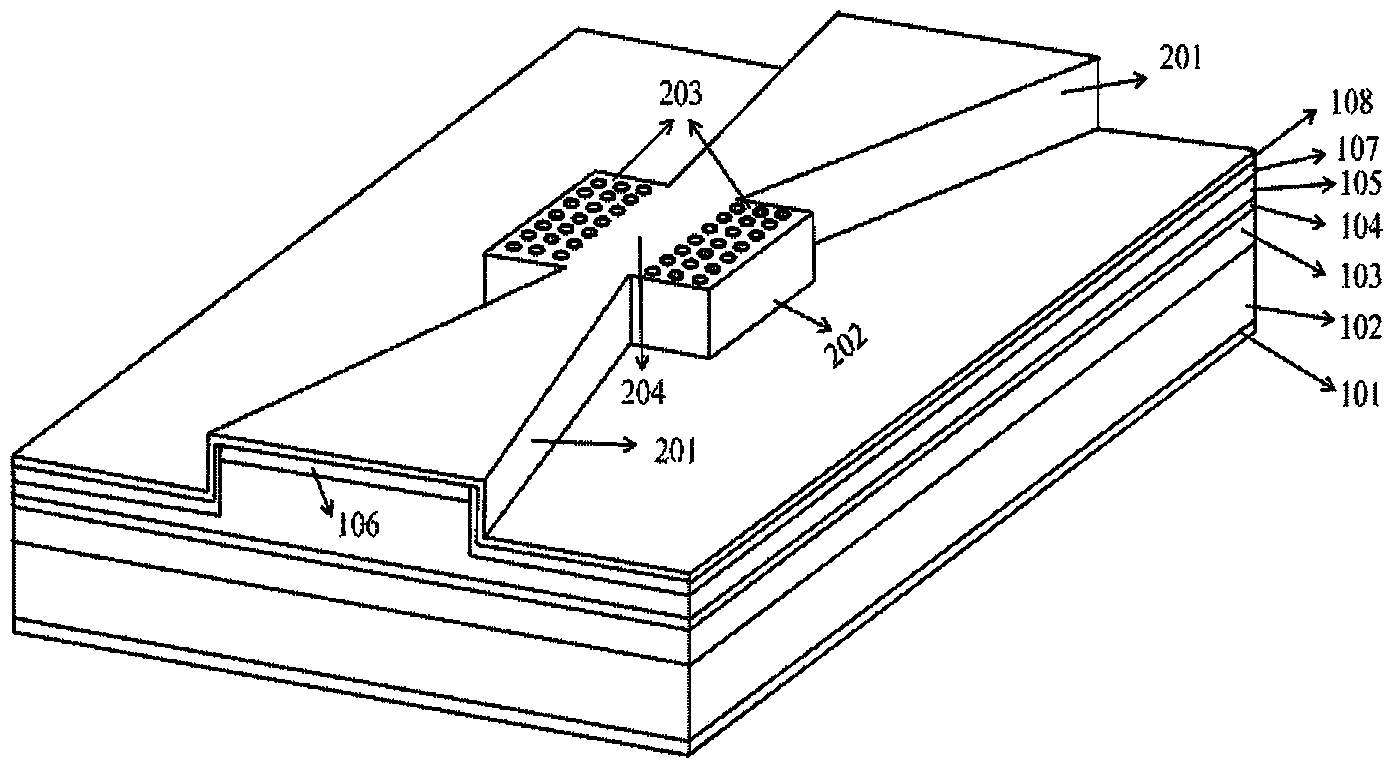

[0038] figure 1 It is a three-dimensional structural schematic diagram of an embodiment of a single-mode photonic crystal edge-emitting semiconductor laser. The lasing wavelength of the semiconductor laser is 913 nm, and the total length of the device is 1300 μm. Among them, the length of the mode selection region is 300 μm, and the length of the two symmetrically distributed mode amplification regions is 500 μm. In the mode selection area, the width of the air hole arrays 203 on the left and right sides of the photonic crystal waveguide 202 is 27.5 μm, the period and duty cycle are 3.05 μm and 0.5 respectively, and the width of the line defect 204 is 5 μm. In the mode amplification region, the width of a single tapered waveguide 201 increases linearly from 5 μm at the narrow port to 60 μm at the wide port. The etching depth of the raised three-section waveguide in the middle of the P-type confinement layer 105 and the air hole array 203 is 1.1 μm.

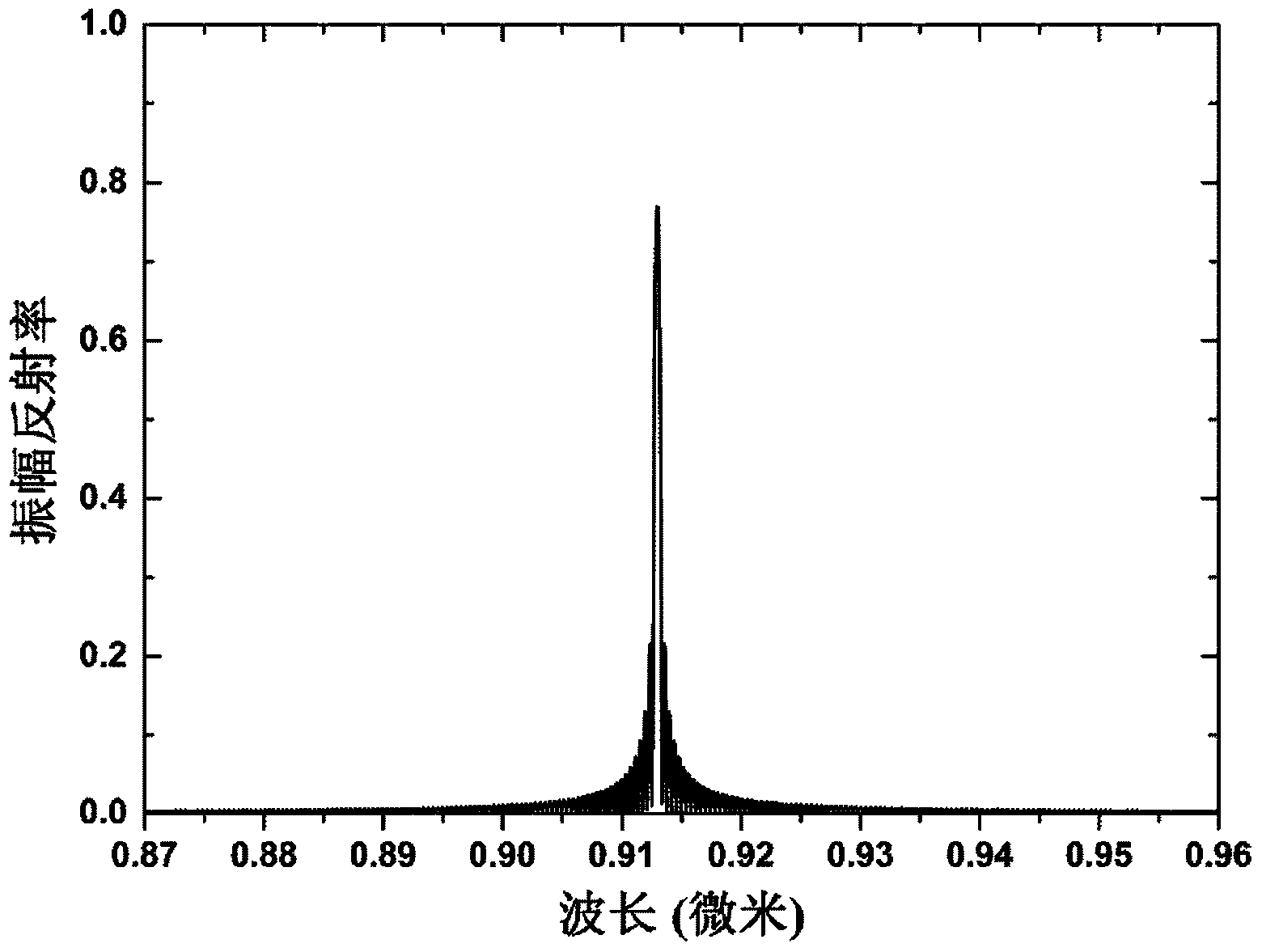

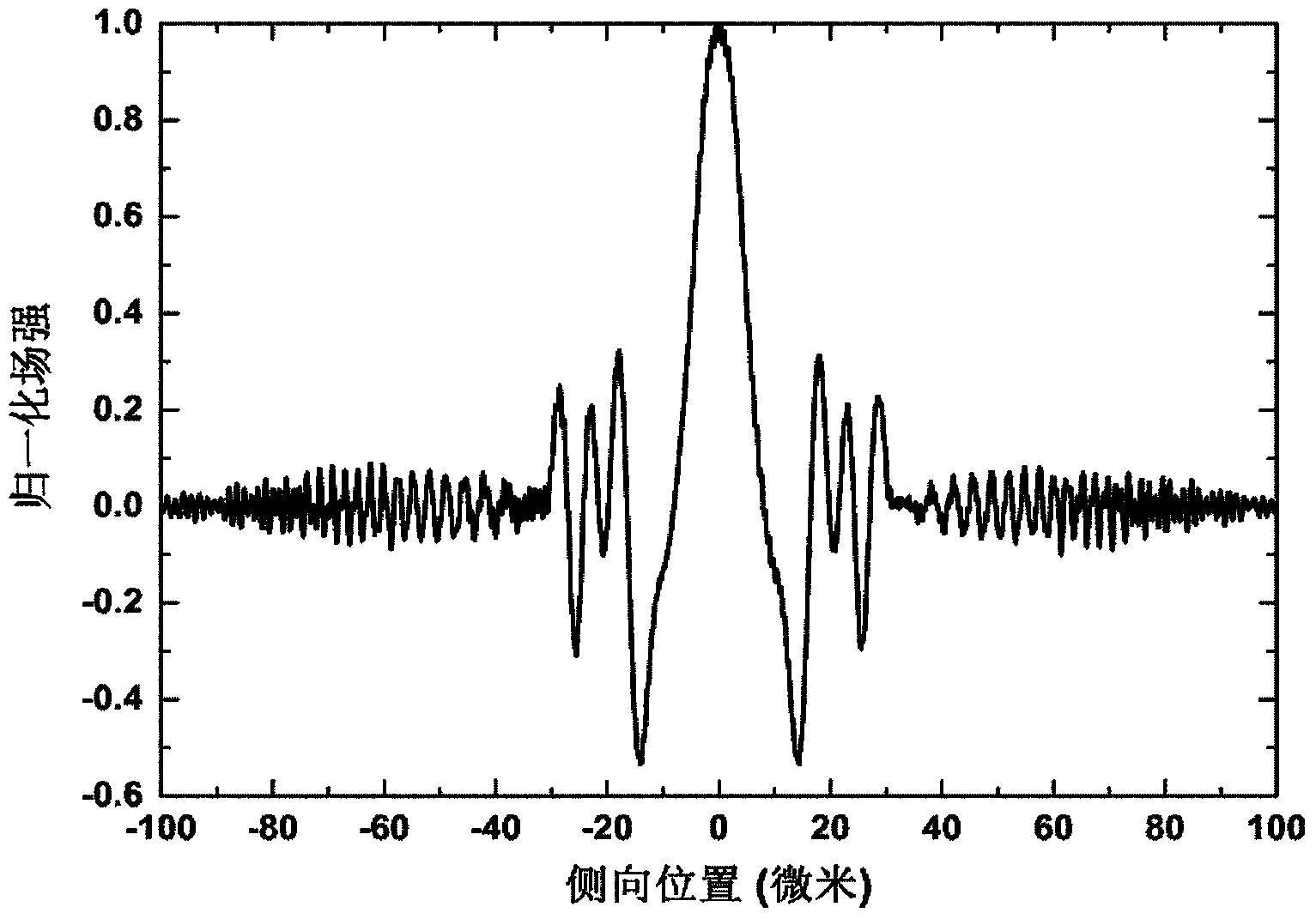

[0039] figure 2 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com