High-speed large-current power field-effect transistor driving circuit

A power field effect tube and drive circuit technology, applied in the direction of output power conversion devices, electrical components, etc., can solve problems that cannot meet high frequency and load capacity applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

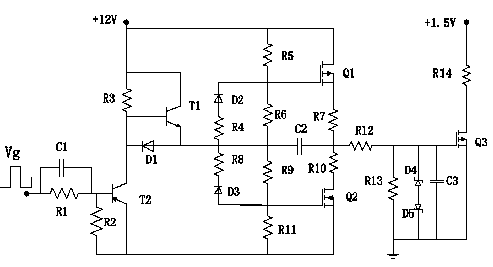

[0018] like figure 1 Among them, the driving pre-circuit is connected with the driving signal Vg, and the driving pre-circuit includes a capacitor C1, resistors R1, R2, R3, a diode D1 and triodes T1, T2, and the capacitor C1 is connected between the driving signal Vg and the base of the triode T2 ; The resistor R1 is connected in parallel with the capacitor C1, the resistor R2 is connected between the base and the emitter of the transistor T2, and the resistor R3 is connected between the emitter and the base of the transistor T1; the anode of the anti-reverse diode D1 is connected to the collector of the transistor T1, The negative electrode of D1 is connected to the collector of the triode T2; the triode T1 is an NPN type triode, the emitter of T1 is connected to the +12V voltage, and the triode T2 is a PNP type triode; the driving rear circuit is connected to the driving object Q3, and the driving rear circuit includes a resistor R12~R13, diodes D4 and D5, capacitor C3 and F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com