Vacuum desorption system and method for adsorption and recovery of organic solvent

An organic solvent, adsorption recovery technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of losing the meaning of purging, the desorption speed cannot be achieved, and the vacuum degree value of the adsorption bed cannot be guaranteed. Achieve the effect of improving flow rate and desorption speed, realizing desorption speed and running cost balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Vacuum desorption system for adsorption and recovery of organic solvents, including an adsorption bed for organic solvents, a nitrogen purging device for the adsorption bed, a vacuum desorption device for desorbing the adsorption bed, and a condensation unit for recovering the desorbed organic solvent The recovery device, the vacuum desorption device is composed of two-stage vacuum pumps connected in series, and the flow rate of the two-stage vacuum pumps is configured to decrease in proportion.

[0028] The flow rate and desorption speed of the vacuum desorption system can be greatly increased by connecting the two-stage vacuum pump configured with a proportional decrease in flow rate, so as to achieve a balance between the desorption rate and the adsorption rate. However, in order to meet the requirement of desorption flow rate in this configuration, at least one level of vacuum pump is required to have a large flow rate, and the energy consumption is high.

Embodiment 2

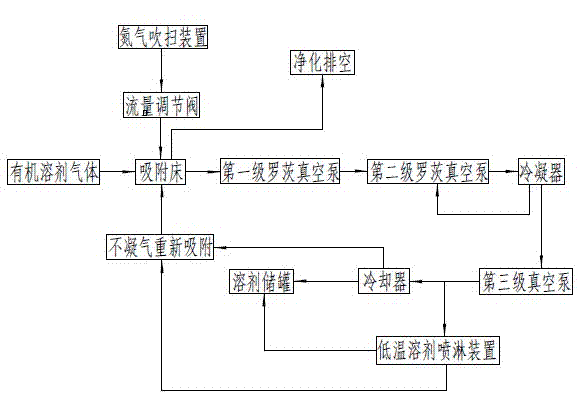

[0030] Such as figure 1 As shown, the vacuum desorption system for adsorption and recovery of organic solvents includes an adsorption bed for organic solvents, a nitrogen purging device for the adsorption bed, a vacuum desorption device for desorbing the adsorption bed, and a desorption process for the desorbed organic solvent. The recovered condensation recovery device, the vacuum desorption device is formed by three-stage vacuum pumps connected in series; the adsorption bed is connected to the first-stage Roots vacuum pump, the first-stage Roots vacuum pump is connected to the second-stage Roots vacuum pump, and the second-stage Roots vacuum pump The vacuum pump is connected to the third-stage vacuum pump, and the third-stage vacuum pump is connected to the condensation recovery device; the flow configuration of the third-stage vacuum pump is: (15-20): (3-5):1. The second-stage Roots vacuum pump is an air-cooled Roots vacuum pump, which is self-cooled through a condenser arr...

Embodiment 3

[0040] Vacuum desorption system for adsorption and recovery of organic solvents, including an adsorption bed for organic solvents, a nitrogen purging device for the adsorption bed, a vacuum desorption device for desorbing the adsorption bed, and a condensation unit for recovering the desorbed organic solvent The recovery device, the vacuum desorption device is a vacuum pump group composed of four-stage vacuum pumps connected in series, and the flow rate of the four-stage vacuum pumps is configured to decrease in proportion.

[0041] Higher vacuum desorption system flow rate and desorption speed can be achieved by connecting four vacuum pumps in series.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com