Honeycomb catalyst production mechanical arm with automatic stacking function

A honeycomb catalyst and manipulator technology, applied in manipulators, mechanical conveyors, conveyors, etc., can solve the problems of complex conveyor line equipment, unable to realize honeycomb ceramic code blocks, unable to meet the urgent needs of air purification, etc., to improve work efficiency, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

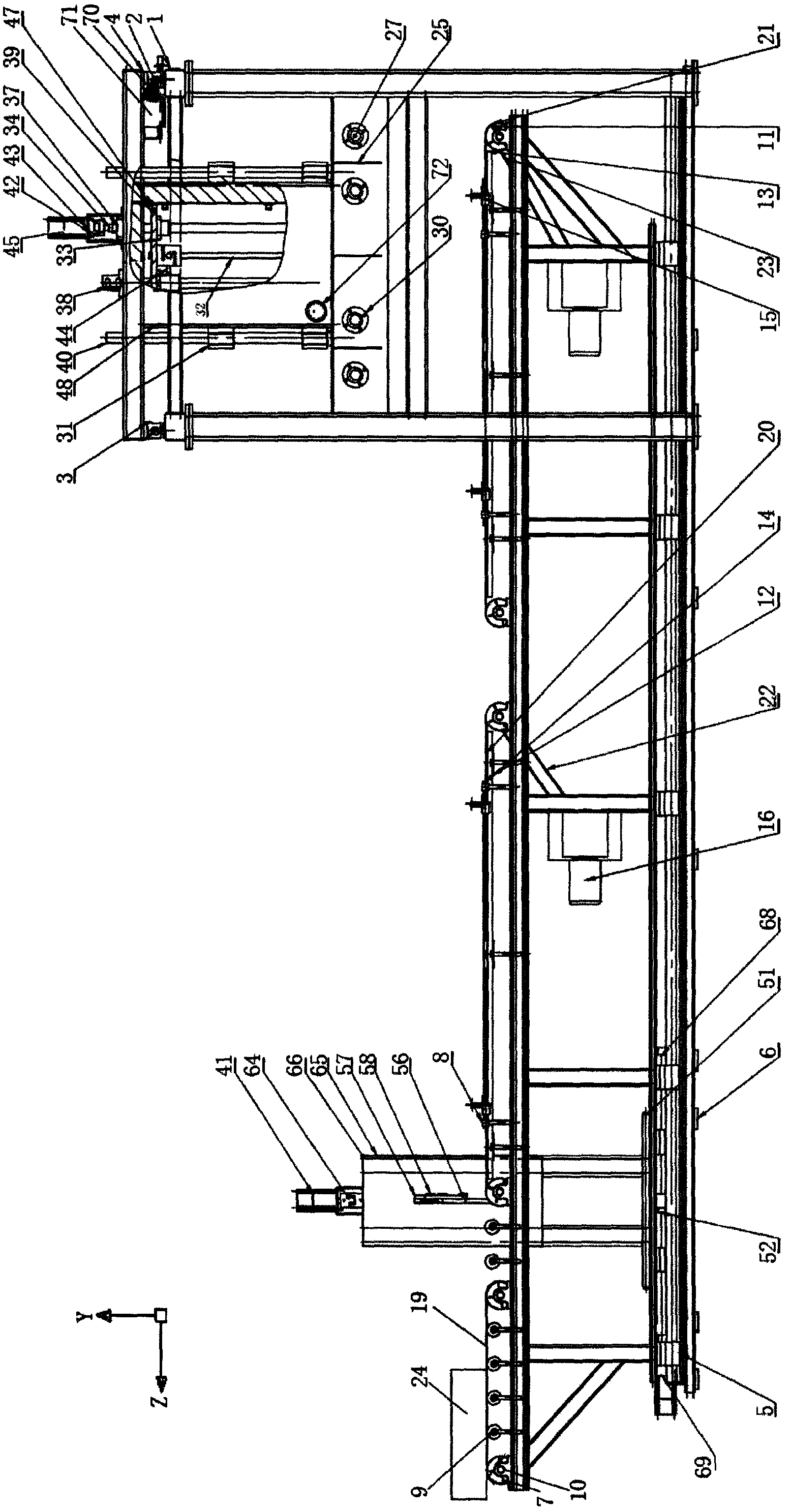

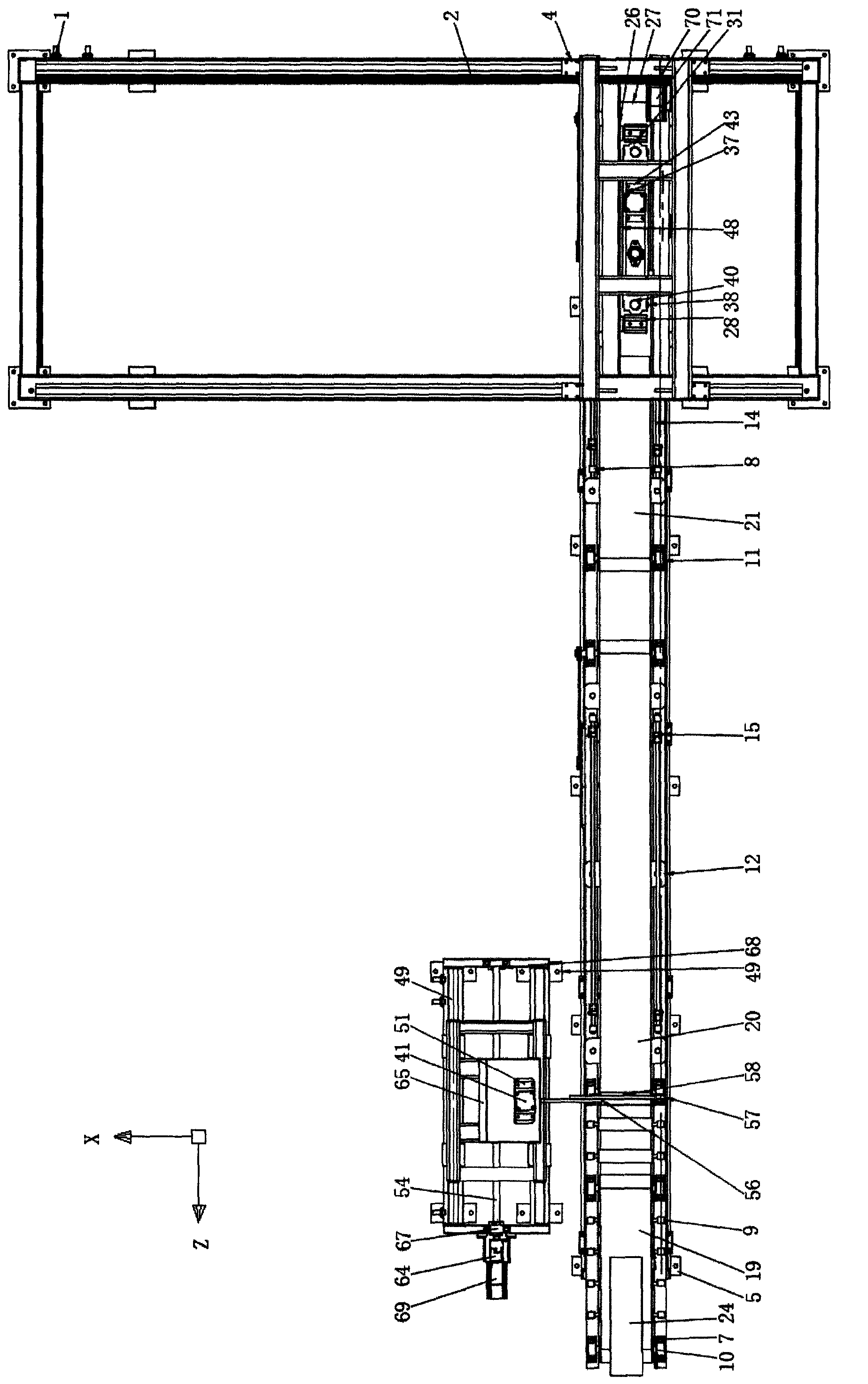

[0025] The following describes the present invention in further detail in conjunction with the drawings and specific implementations:

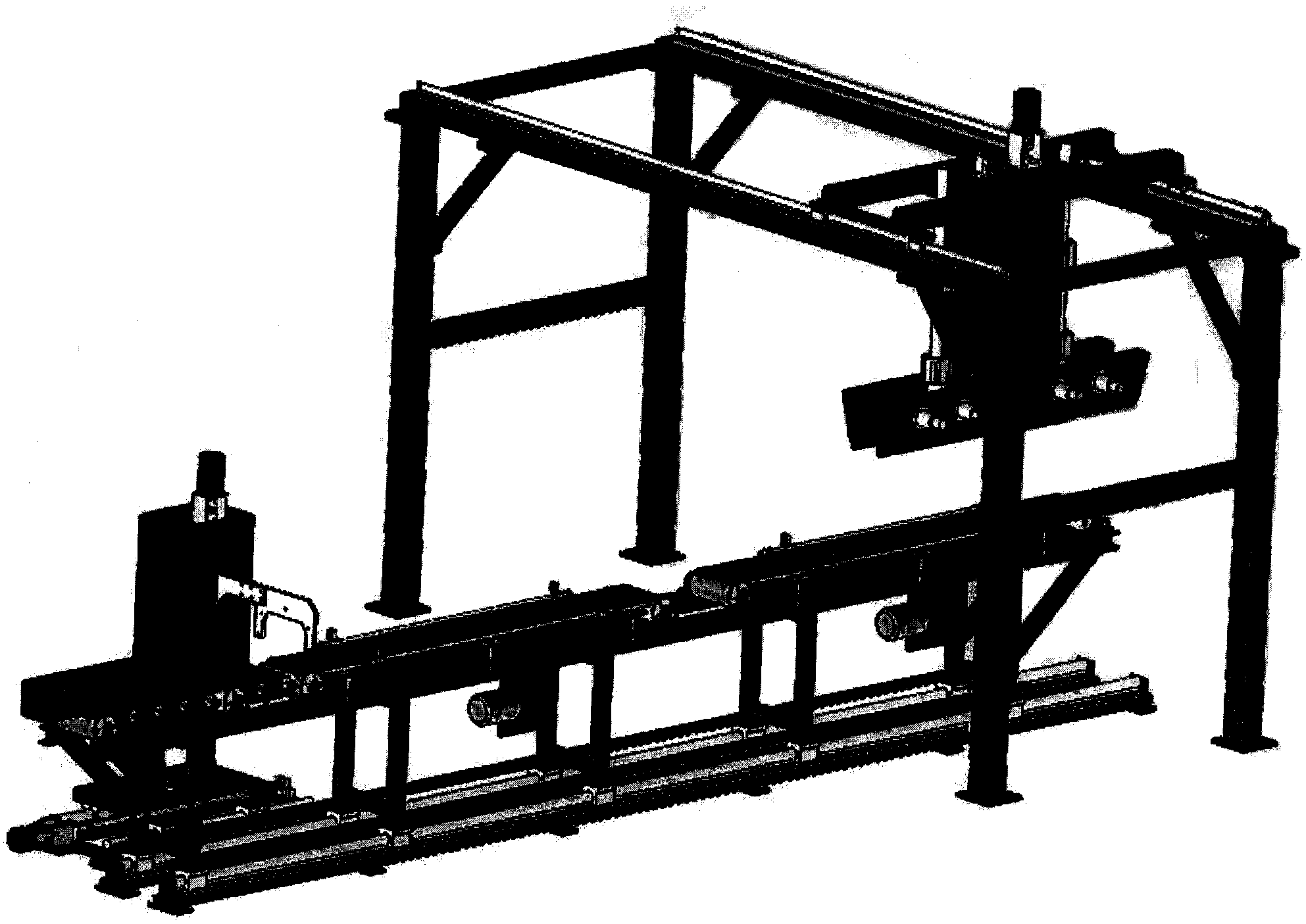

[0026] See figure 1 , figure 2 , Automatic code block honeycomb catalyst production manipulator, including three parts: cutting mechanism, conveying mechanism and manipulator mechanism.

[0027] The cutting mechanism is used to realize the cutting of cutting material. It includes a first servo motor 41, a cutting frame 51 and a cutting hand 57; a first servo motor 41 is arranged above the cutting frame 51, and the first servo motor 41 is connected to the cutting frame 51 through a first coupling 64 for control The movement of the cutting hand 57; the cutting frame 51 is connected to the cutting hand 57 through the cutting board connecting block 56; the cutting hand 57 is fixed with a rotatable wire wheel 58 with a cutting line on the wire wheel 58 which is driven by rotation The cutting line is used to cut the cutting material 24. The cutting fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com